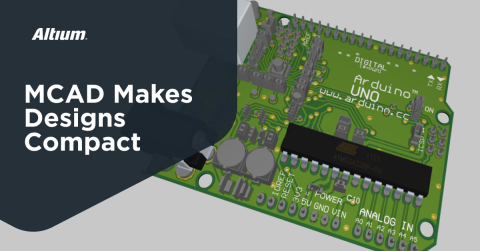

Beyond the Guess: Eliminating the Thermal Blind Spot with Native 3D Copper Geometry

For most electronic product teams, thermal failure isn't just an engineering inconvenience, but a business emergency. When a product overheats, the time-to-market clock stops, and the cost of a design re-spin easily explodes into the tens of thousands of dollars. The ultimate penalty is a catastrophic late-stage failure that confirms your electrical, mechanical, and supply chain disciplines were never truly aligned.

Modern product development demands design confidence. To truly empower procurement and manufacturing, engineering teams must eradicate this risk at the source by eliminating the primary thermal blind spot in mechanical validation: the reliance on guessing the thermal performance of the PCB’s most critical heat spreader - the copper itself.

The ability of a modern ECAD-MCAD workflow to transfer precise 3D copper geometry is the single most powerful tool for mitigating this thermal risk and securing the integrity of the final design. We simply cannot afford to have mechanical validation run on flawed data.

Key Takeaways

- Estimating PCB copper behavior instead of modeling real 3D copper geometry creates a “thermal blind spot” that can cause simulations to miss critical hot spots.

- Legacy ECAD-MCAD exchanges (e.g., STEP/IDF without intelligent copper data) force MEs to use synthetic “effective conductivity,” turning an excellent conductor into a near-insulator in the model.

- The guesswork leads to two big business risks: expensive re-spins from thermal failures and inflated BOM costs from over-engineered cooling solutions.

- A modern ECAD-MCAD Codesigner workflow that transfers native 3D copper geometry enables high-fidelity, traceable simulations, giving engineering and procurement the confidence to optimize thermal design without over- or under-specifying.

The Fatal Flaw of Estimation: Modeling a Conductor as an Insulator

The mechanical engineer (ME) is tasked with solving a conjugate heat transfer problem: predicting how heat spreads from components through the PCB into the cooling system. However, traditional data exchange protocols (like legacy STEP or IDF files) sabotage this effort.

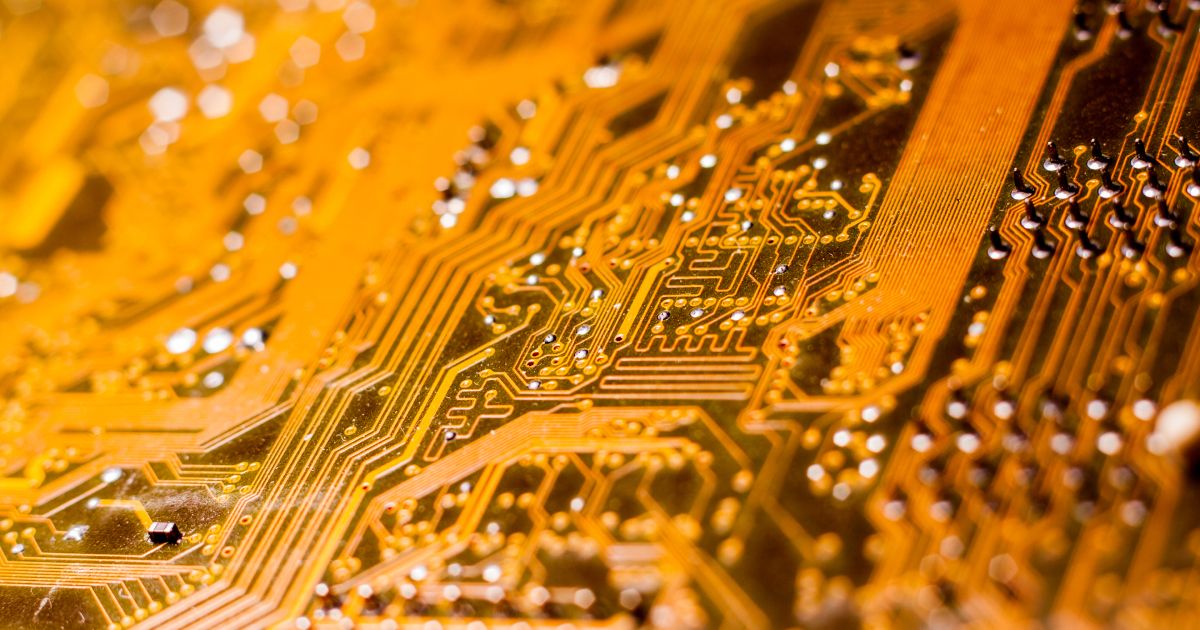

The core technical issue lies in the vast difference in thermal conductivity:

- Copper: An exceptional heat conductor at roughly $385 \ W/mK$. This is the primary heat sink.

- FR4 Dielectric: An insulator at only $0.3 \ W/mK$.

When the ME receives the PCB data, the detailed copper features (planes, traces, thermal reliefs) are either omitted or sent as simple graphics, lacking the necessary geometric intelligence for FEA/CFD solvers.

The missing data forces the ME into a costly, unreliable workaround: the forced estimation.

- Manual Guesswork: The ME must assign a synthetic material property, known as the effective or orthotropic conductivity, to the entire PCB block. This is a best guess based on estimated copper coverage (often $10 \ W/mK$ to $15 \ W/mK$).

- The Flaw: This estimation smooths out the heat distribution in the simulation, failing to predict critical hot spots that occur when heat is forced to flow only along thin traces or through congested vias.

By substituting a $385 \ W/mK$ conductor with a synthetic, low-conductivity estimate, the simulation inevitably underestimates the peak junction temperatures. This is the thermal blind spot that guarantees a failure when the prototype reaches final testing.

The Dual Financial Risk: Costly Consequences

Relying on estimation creates two significant financial risks that directly impact the bottom line:

Risk 1: Catastrophic Failure (The Respin Cost)

When the simulation underestimates the peak temperature, the resulting cooling system is insufficient. The product fails thermal testing, forcing an immediate, mandatory design respin. Procurement must halt orders and source new, expensive thermal solutions, leading to budget overruns and delayed market entry.

Risk 2: Wasteful Over-Engineering (The BOM Bloat)

Conversely, if the engineer is overly conservative, they will overestimate the cooling needs. They specify unnecessarily oversized fans, high-cost thermal interface materials (TIMs), or heavy heatsinks. This bloats the Bill of Materials (BOM), forcing procurement to buy components that are more expensive, heavier, and bulkier than necessary, directly cutting into product profitability.

From Approximation to Authority: The Guarantee of Data Integrity

The modern ECAD-MCAD Codesigner workflow eliminates these risks by guaranteeing data integrity. Instead of relying on static file translations, the Codesigner facilitates the transfer of the actual, native 3D copper geometry as intelligent CAD data, ready for immediate FEA simulation.

What This Means for Risk Mitigation

- High-Fidelity Simulation: The ME runs simulations using the exact copper features designed by the electrical team. This removes all assumptions and ensures the results are grounded in the final, manufacturable design, eliminating the thermal blind spot. This includes the critical transfer of interlayer copper, such as the copper barrels of plated holes and vias, which are essential for accurate Z-axis (vertical) thermal flow simulation.

- Real-Time Validation: Because the design data is synchronized and tracked (Traceability), the ME knows the copper geometry they are simulating is the same geometry the electrical team is designing.

- Procurement Confidence: With a high-fidelity thermal analysis complete, the engineer gains the design authority to confidently sign off on optimized thermal solutions. Procurement can order materials knowing the specifications are precise, neither leading to failure nor wasted cost.

By leveraging a Codesigner solution that guarantees the integrity of the 3D copper data, the mechanical team moves beyond the guesswork to designing with complete confidence. To explore the full depth of this ECAD-MCAD Codesign workflow and see how this collaboration empowers Agile Teams, learn more about our integrated solutions today.