PCB Designer Mike Brown Offers Advice: Stay Hungry, Keep Growing, Nurture Relationships

Mike Brown is a PCB Design Consultant. He caught the design-bug at the tender age of 17 and has never looked back. Recently, he shared the story of his career path from being a young, to design manager, to entrepreneur and finally selling his company, Interconnect Design Solutions (IDS), last year to the Maryland-based contract manufacturer, Zentech Manufacturing.

Warner: Mike, looking back, what indicators can you see from your childhood that suggested you might become a PCB one day?

Brown: I loved erector sets and fixing anything from a spring-loaded curtain rod to a car door handle. I wanted to know how everything worked. I have a captioned photo of myself from the fourth grade that says, “what I want to be when I grow up” and there’s a drafting table in the background. That’s what I wanted to do – I wanted to design “stuff”.

Career Day 4th Grade (drafting table in background)

Warner: I often say no one becomes a PCB on purpose; people tend to “fall” into this line of work. How did you come to be a ?

Brown: I aspired to be an architect when I was in high school. I was in a tech program, offered by my high school, and I excelled in drafting. There was a work study co-op opportunity I participated in when I was a senior.

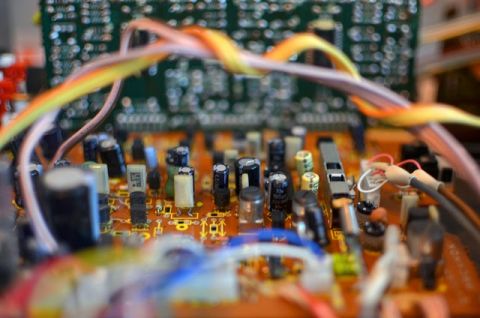

That first job involved mechanical drafting on a drafting table with a pencil before CAD was mainstream, creating technical drawings for computer peripherals, and sheet metal enclosures.

That is where I met my first mentor, Mary Kerbe, who became my boss at a small telecom company called Commtex. She gave me the opportunity to learn simple designs using a tool called P-CAD®. I was a sponge – I was having fun learning a specialized skill, getting paid while at the same time earning class credits. I was 17 years old and just finishing high school when I had designed (replicated actually, lol.) my first board.

Mary and I are still in touch and have worked together throughout my career--eventually, the student became the teacher, so to speak. After Commtex closed their doors, I followed Mary (as her protégé’) to several companies over the years: Entek, GE, Lockheed-Martin, and CTA Space Systems.

I grew tremendously over the years. I helped develop products for avionics space flight supporting customers such as NASA and Naval Research Labs. It’s an amazing sense of accomplishment knowing that you have had a part in developing something that will have a positive impact.

After this time I moved to Rochester, New York and did some contract work for Kodak designing boards for satellites. Who knew Kodak was involved with satellites? That is when I met my second mentor, Manny Marcano from EMA Design Automation. Through my relationship with Manny, I gained exposure to other EDA tools, such as ViewLogic (now DX-), OrCAD / Allegro and my resource network started to grow.

After my contract with Kodak was up, I went back to Maryland and Orbital Science (now Orbital-ATK) to once again work with my mentor Mary Kerbe, making products that would live in space for 10-20 years.

The work was a bit slow paced and repetitive for my liking at the time, so I went to work for Ciena Corp (specializing in DWDM - expanding bandwidth in the Datacom market developing optical networking systems) from 1997-2012. I started as a Sr. , then became a Group Lead.

Next thing you know, I was responsible for leading various design teams on a global scale with 5 teams in three different countries and various time zones. We were developing state of the art equipment virtually around the clock. It was truly an amazing accomplishment not only in product development but in teamwork and collaboration like no other.

All of my fellow designers were truly skilled in their craft; whom I have a deep respect for. I remained an , even though I was a manager--which I think was an important choice. I used many tools such as PADS, Allegro, Valor, CAM350, AutoCAD, ADIVA and Gerbtool.

In 2012 Ciena made some organizational changes where I as well as many of my colleagues were, unfortunately, let go. It was a business decision that many companies face, nothing personal. Buy hey – when one door closes, another opens. In hindsight, my tenure, experience, relationships and work ethic would pay off.

From late 2012 to early 2013 I started IDS (Interconnect Design Solutions) in Atlanta - it was a scary sink-or-swim chapter in my life! I pulled upon all my resources and relationships I had built over the years. The engineers that had disbursed from Ciena ended up at many different companies. However, we stayed connected and in communication, especially through LinkedIn.

Through these relationships, along with the help of Mary and Manny, I quickly had work from Orbital, EMA, Trilogic, and many others all because of a good reputation and strong relationships built over many years. I attended countless trade shows, fostered relationships via LinkedIn and made sure I didn’t stay invested in a single EDA tool.

Around 2014, I began getting job requests using Altium Designer® and added that tool to my product offering in addition to an already established customer base using PADS & OrCAD / Allegro.

Within six months of being in business, I won a substantial contract through an independent rep with key customers in the mid-Atlantic region which enabled both his company and mine to experience major growth and to expand. I began doing a lot of work for Zentech Manufacturing between 2013 and 2016. Over time, I built a team of nine designers that worked with IDS.

Zentech (based in Maryland) was in need of design support. I spent the majority of my life in Maryland and was familiar with many of their customers, and had many existing relationships in the area. It was a natural fit! I began attending customer meetings with Zentech which cultivated trust and helped everyone to thrive and succeed. By 2016 IDS was experiencing 300-400% growth and Zentech made an offer to acquire IDS, which I accepted.

Warner: You’ve clearly had a very successful career in PCB Design. What would you say are some of the keys to your success?

Brown: In order to be successful, a designer has to be able to address the designs in a wide variety of markets and be proficient in many different EDA tool sets. If you’re going to build a house, you don’t just show up with a hammer to do the job. The same goes for design; you need a wide variety of tools and skills.

There is no degree path for PCB layout. Therefore, you have to be willing and able to continually learn at an engineering level and continually take on more. You’re 100% responsible for self-education; if you don’t, you risk becoming irrelevant very quickly. Technology changes and moves too fast to stop growing – you have to keep pushing forward to learn new materials, new techniques, and new tools.

Warner: In discussions we’ve had in the past, it’s very clear you have a depth of knowledge regarding both PCB Fabrication and Assembly which is a major asset as a PCB designer. How did you acquire that knowledge, and what suggestions would you give to other designers to gain this understanding?

Brown: I was fortunate that I learned about DFM while with Ciena. I was part of their quality audit team and visited many PCB fabricators which was a learning experience. Ciena had an in-house assembly facility when I first started there, which also gave me an invaluable access and understanding of how my design choices impacted the assembly process.

As far as advice I would give, I would say self-education again. Make or take the opportunity to learn to solder in-house, take the time to understand why you have to route a a certain way (component manufacturers often provide reference designs to source), visit a board fab shop to really learn and understand the fabrication process – ask a lot of questions, tour an assembly house or Electronic Contract Manufacturer. Build relationships with your CM to learn about their processes as a whole. Ask other designers on forums, participate in IPC, attend trade shows. Don’t be afraid to ask questions: Why do they use tooling holes? Why do they make a panel array for assembly? Ask lots of questions and never stop learning!

Warner: One final question, Mike. I’ve noticed there seems to be a trend of EMS or CM companies either having design services in-house, or purchasing a capable design firm much like Zentech did with IDS. What do you think is driving this trend?

Brown: The trend is this; there has been an economic downturn where engineering firms don’t want to carry in-house designers on their payroll due to the overhead burden and EDA tool cost. For the same reason, many OEMs don’t want to have to employ their own designers. This has caused a migration of designers out of the engineering firms and OEMs to the EMS and CM level. At this level, many designers are exposed to a broad product mix and EDA tools. It also gives them exposure to the manufacturing and supply chain which means DFM becomes stronger and a more integrated part of the design process.

Warner: Final thoughts?

Brown: PCB designing is a great vocation and career. Unfortunately, the available pool of designers is shrinking because there is not a direct academic path with many experienced designers who really know their stuff starting to retire. The current available academic path is tailored to the Double-E or perhaps an EET degree and not focused on the specialized skill of board layout & design. As an industry, we need to find a way to expose young people to PCB design and give them a path they can follow. Mentorships are really key at this point to going from a “CAD Guy” to an experienced and well-respected designer in the engineering community.

Warner: Thank you so much for telling us about your amazing journey as an accomplished PCB professional, Mike. Wishing you continued success!

Brown: Thank you, Judy.