Wire Harness Design Guide for Development, Manufacturing, and Compliance

Wire harnesses play a vital role in modern electronics, keeping electrical systems organized, safe, and efficient. From automotive and aerospace to industrial manufacturing, they streamline wiring by bundling cables into a single, manageable assembly. Understanding their design and development is essential for ensuring reliable performance across various industries.

Why Electrical Wire Harnesses Matter

A wire harness is a structured grouping of wires, connectors, and protective materials that transmit electrical signals and power. Instead of dealing with a chaotic tangle of cables, engineers and manufacturers can use wire harnesses to simplify installation, improve durability, and enhance overall safety.

Beyond keeping things tidy, wire harnesses help reduce the risk of electrical failures caused by loose or damaged wiring. They also cut down on installation time, making them an invaluable part of any electrical system. By choosing the right design, businesses can improve efficiency, minimize waste, and lower production costs.

The Step-by-Step Process of Electrical Wire Harness Design and Development

Developing a wire harness design follows a structured approach to ensure efficiency, reliability, and compliance with wire harness industry standards. Each step is crucial in achieving a durable and high-performance end product.

- Requirement Analysis: Engineers begin by assessing the electrical and mechanical requirements, considering voltage, current loads, temperature ranges, and environmental constraints. This ensures the harness aligns with the intended application.

- Component Selection: The right materials are crucial before the design phase. Engineers determine the appropriate wires, connectors, terminals, and insulation materials based on electrical capacity, mechanical stress, and environmental resistance.

- Schematic and Wiring Diagram Development: Once the components are selected, engineers create detailed schematics and wiring diagrams. The schematic provides a conceptual electrical layout, defining component interactions and signal flow. The wiring diagram, in contrast, specifies the physical connections and integration within the system.

- Harness Layout Design: Engineers focus on the harness's physical arrangement of wires and components. The layout ensures optimal wire routing, flexibility, ease of installation, and proper strain relief to prevent mechanical stress and potential failures.

- Prototyping and Testing: A prototype is developed and subjected to rigorous testing to validate electrical continuity, mechanical strength, and environmental durability. This phase ensures the design meets safety and performance wire harness standards before full-scale production.

- Final Inspection and Manufacturing: Once the prototype passes all tests, the final harness design is approved, and production begins under strict quality control measures. Advanced manufacturing techniques and automation ensure consistency, efficiency, and long-term reliability.

A well-executed electrical wire harness design enhances system performance, simplifies installation, and ensures durability in various operational environments.

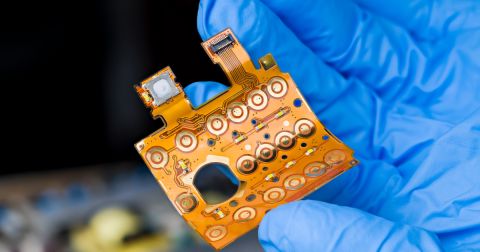

Electrical Wire Harness Manufacturing: Essential Components and Materials

A well-made wire harness relies on high-quality materials and components. The core elements include:

- Connectors and Terminals: Ensure secure links between system parts, preventing signal loss and electrical failures.

- Wires and Cables: Usually made of copper or aluminum, selected based on current capacity and application needs.

- Insulation Materials: PVC, Teflon, and silicone are commonly used to protect wires from heat, moisture, and electrical interference.

- Protective Sleeves, Clips, and Grommets: Shield wires from environmental stressors like abrasion, moisture, and extreme temperatures.

Material selection is especially critical for applications that demand high durability, where resistance to heat, chemicals, and mechanical stress is essential to long-term reliability.

Electrical Wire Harness Design Challenges and How to Overcome Them

Designing wire harnesses comes with unique challenges, from fitting components into tight spaces to ensuring long-term durability in harsh environments. Engineers must consider factors like routing efficiency and regulatory compliance to create reliable and high-performance assemblies. Here’s a look at some common harness design challenges and strategies to overcome them.

- Space Constraints: In compact environments like automotive dashboards, designing a wire harness that fits without compromising performance can be challenging. Flexible wiring materials and optimized routing strategies help engineers maximize space while maintaining reliability.

- Environmental Exposure: Wire harnesses often face extreme conditions, including heat, moisture, and vibrations, which can degrade them over time. Choosing heat-resistant insulation materials and incorporating protective sleeves enhances durability in harsh environments.

- Complex Routing Requirements: Managing multiple wires in confined spaces requires careful planning. Engineers use advanced CAD tools to optimize routing and minimize interference, ensuring proper wire organization without tangling or signal loss.

- Compliance with Wire Harness Industry Standards: Regulatory standards like ISO 9001 and IPC/WHMA-A-620 ensure that wire harnesses meet safety and performance requirements. Implementing strict testing and quality control measures helps manufacturers stay compliant while delivering high-quality products.

Custom vs. Pre-Made Electrical Wire Harnesses: Which One Is Right for You?

Manufacturers must decide between pre-made and custom solutions when sourcing a wire harness. Each option has advantages, depending on the application’s requirements.

Pre-made wire harnesses are cost-effective solutions for standard applications. They are mass-produced with industry-standard configurations, making them readily available and efficient for general use.

Conversely, custom wire harnesses are tailored to meet specific application needs. They offer flexibility in wire length, material choice, and component configurations, making them ideal for unique or high-performance applications. While custom harnesses may require longer production times and higher costs, they ensure optimized performance and durability in specialized environments.

The Future of Electrical Wire Harness Design Technology

As industries evolve, wire harness technology is advancing in several key areas:

- Smart Wire Harnesses: Integrating sensors and diagnostic capabilities enables real-time monitoring of wire conditions, reducing maintenance costs and preventing failures.

- Lightweight Materials: The transition toward electric vehicles and aerospace efficiency is driving the use of aluminum and composite materials to reduce weight without compromising performance.

- Modular Harness Designs: Standardized harness modules allow quick customization and assembly, reducing production time and costs.

The Role of Automation in Electrical Wire Harness Manufacturing

Automation integration in wire harness manufacturing transforms efficiency, precision, and scalability. Key advancements include:

- Automated Wire Cutting and Stripping Machines: Enhance accuracy and speed in wire preparation, reducing production time.

- Robotic Assembly Systems: Automate the placement and securing of wires, connectors, and terminals, minimizing human error and improving consistency.

- Data-Driven Manufacturing: Real-time monitoring and analytics optimize production, detect defects early, and enhance quality control.

- Automated Testing and Validation: Advanced testing technologies ensure compliance with wire harness industry standards, reducing failures and recalls.

As automation advances, manufacturers can expect lower labor costs, faster turnaround times, and consistently high-quality wire harnesses that meet the growing demands of modern industries.

Electrical Wire Harness Designs Moving Forward

Wire harnesses are critical components of contemporary electrical systems, providing organized and dependable connectivity. A well-designed harness streamlines installation, protects components, and ensures optimal electrical performance across diverse sectors.

The decision between pre-fabricated and bespoke harnesses depends on the application's specific requirements. Custom-made solutions offer tailored precision and enhanced performance.

Automation is revolutionizing manufacturing, yielding increased efficiency, cost reduction, and consistent quality in wire harness production.

As technology advances, wire harness manufacturing will continuously evolve, shaping the future of electrical connectivity. Organizations that adopt these innovations will maintain a competitive edge, delivering high-performance solutions that fulfill the ever-changing requirements of contemporary industries.

Want to seamlessly design wiring for your harness? Experience the power of wire harness design in Altium Develop.