Cybersecurity in Wire Harness Networks: Protecting Connected Vehicles & Systems

As vehicles evolve, they are no longer just a form of transportation. They can now function as smart, connected hubs for data and communication. With the rise of electric vehicles, autonomous driving technologies, and cloud-linked features on the rise, the complexity of the wire harness networks that support these innovations continues to expand.

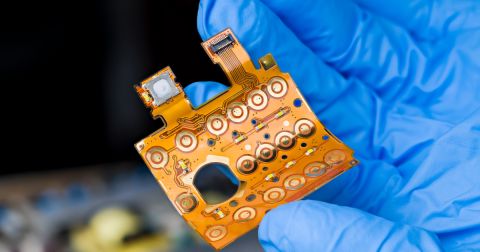

Wire harnesses, once limited to power and signal distribution, now facilitate data exchange, system control, and external communication. However, as vehicle connectivity expands, so do cybersecurity risks.

The Increasing Need for Cybersecurity in Modern Vehicles

Cybersecurity in the automotive domain has become a high-stakes issue. Hackers constantly probe for vulnerabilities, and modern electric vehicle wiring systems, which are now responsible for managing essential operations, have become prime targets. Data transmitted through these harnesses could provide entry points to vehicle controls, braking, steering, or even personal driver information.

To address these threats, manufacturers must reframe how they approach harness design. Automotive cybersecurity must factor in from the start, not as an afterthought. This is where advanced wire harness design software plays a pivotal role.

What Are the Cyber Threats Facing Wire Harnesses?

1. Intercepting Data and Unauthorized Access

Data interception poses one of the most serious risks. Wire harnesses now transmit extensive information across vehicle systems, sensors, and cloud interfaces. Without protection, hackers could manipulate functions such as acceleration, braking, or steering.

Even standard CAN bus networks or Ethernet links routed through the harness may serve as access points. Attackers could exploit unprotected systems to take control or extract sensitive data. Robust encryption and secure communication protocols help close these gaps and support secure auto networks.

2. Malicious Firmware and Software Updates

Modern vehicles increasingly rely on over-the-air (OTA) updates for performance enhancements and new features. However, these updates, if unprotected, can become channels for an injection of malicious firmware or software updates. A compromised OTA process could lead to system malfunctions or a loss of control over key operations.

OTA convenience must be matched with strong safeguards. Without a secure delivery mechanism built into the electric vehicle wiring system, attackers can exploit exposed pathways.

3. Electromagnetic Interference (EMI) and Signal Manipulation

Digital threats dominate headlines, but physical-layer attacks remain a real concern. EMI poses a serious risk, particularly in electronics-heavy vehicles. Signal manipulation through EMI could disrupt communication between subsystems like braking or navigation.

To reduce susceptibility, engineers must apply proper shielding and strategic wire routing. These physical protections are key to maintaining wire harness protection in electric vehicles, especially in dense electrical environments.

4. Physical Tampering and Vulnerabilities

Unauthorized access to the wire harness itself remains a concern, particularly during service or maintenance. Attackers could install malware or modify circuits via exposed connectors or terminals. This kind of direct manipulation undermines overall system integrity.

Embedding tamper-resistant features and limiting physical access through design helps reduce these risks.

How Can Wire Harness Design Software Address These Cybersecurity Challenges?

The best way to address these growing cybersecurity concerns is through intelligent wire harness design. With the right software, manufacturers can integrate cybersecurity into every phase of wire harness creation, from initial design to manufacturing and beyond. Here's how:

1. Proactive Risk Detection and Threat Analysis

Modern design software enables engineers to identify potential vulnerabilities early in development. These tools perform automated scans during layout creation, flagging risk areas before production begins. This proactive model integrates cyber security in the automotive domain rather than layering it on after the fact.

The software also ensures compliance with standards such as ISO/SAE 21434, which governs vehicle network security and lifecycle risk management.

2. Secure Communication and Data Encryption

Engineers must now build secure communication paths across all system nodes. Wire harness software allows them to embed encryption protocols directly into the design, which allows them to build secure data transmission systems and helps prevent unauthorized access to vehicle networks.

This step is essential to maintain secure connections between sensors, control units, and cloud-based systems.

3. Digital Twin Technology for Real-Time Testing

By simulating wire harness systems digitally, engineers can test for performance and vulnerabilities before any physical build. This digital twin model enables real-time monitoring and scenario testing, such as simulated cyberattacks or EMI interference.

These simulations support CRIND data protection through secure wiring by exposing weaknesses in control or data pathways before production.

4. Optimized Routing and Physical Protection

Strategic routing and physical layout choices are just as important as digital protections. Engineers can use design tools to avoid exposed harness paths, specify shielding, and select tamper-resistant components.

Design software helps create routes that reduce exposure, ensuring both data integrity and physical security.

5. Safeguarding Firmware Updates and Over-the-Air Security

As OTA updates become a standard feature in connected vehicles, securing the delivery pipeline becomes mandatory. Wire harness design tools can support secure update mechanisms, integrating authentication and encryption directly into the system’s architecture.

This process ensures only trusted updates reach the vehicle’s ECUs, further strengthening vehicle network security.

Future-Proofing Your Wire Harness Design Against Cyber Threats

As the automotive industry moves toward fully connected and autonomous platforms, manufacturers must treat wire harnesses as cyber-physical assets. No longer just passive carriers of current, these components now serve as the backbone of connected vehicle systems.

With intelligent design, manufacturers can bake cybersecurity into every layer—from physical routing to digital protocols. By integrating intrusion detection systems (IDS), strong encryption, and real-time testing, engineers can ensure their systems withstand both current and emerging threats.

Ready to take the next step in securing your wire harness systems? Learn how Altium Develop can help you build robust, cyber-secure wire harness solutions for tomorrow's vehicles.