Top 5 Hidden Challenges of Cable Harness Design in Electronic Products

Cable harnesses power and interconnect critical components in electronic products, which ensures each system functions reliably. Despite their importance, designing harnesses introduces complications that often delay development, inflate costs, and compromise quality.

In this blog we review the five recurring challenges in cable harness design and explain how Altium's multi-board and harness tools counter each one with practical, engineering-driven solutions.

Challenge 1: Coordinating Multi-Board Systems with COTS Components

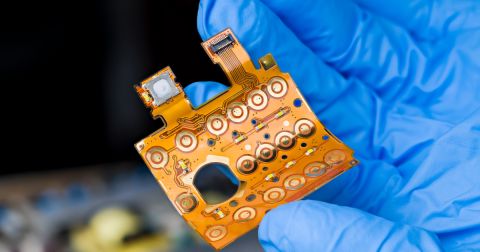

Modern electronic devices depend on multiple interconnected PCBs. These boards link via cable harnesses and often include Commercial Off-The-Shelf (COTS) components. Without precise interconnections, teams risk severe integration issues.

The Altium Advantage

- Multi-Board Schematic Integration: Altium embeds board connectors and COTS components directly into the schematic, which ensures seamless inclusion.

- Streamlined Synchronization: Multi-board schematics synchronize directly with cable harness designs, minimizing connection mismatches and enhancing design consistency.

- Pin Mapping and Validation: Engineers can efficiently map and validate connections, ensuring precision and significantly reducing the need for rework.

Multiboard Schematic – A high-level system design illustrating board-to-board connections

Challenge 2: Keeping Pace with Rapid Design Iterations

As prototypes evolve, design teams must frequently revise cable harness layouts to reflect shifts in PCB structure or component placement. Manual update can create friction, waste time, and lead to errors.

The Altium Advantage

- Real-Time Synchronization: Updates to connectivity or PCB designs are seamlessly reflected in cable harness designs, maintaining consistency throughout the process.

- Iterative Flexibility: Automated updates eliminate the need for manual adjustments, enabling faster and more efficient design iterations.

- Version Control: The inbuilt version control system is optimized for full traceability and transparency by knowing who changed the project, when, and why.

Design changes in Altium - Track full project history

Challenge 3: Integrating Mechanical and Electrical Constraints

Effective harness design balances mechanical durability with electrical performance. Factors such as tight bends, limited mounting options, and enclosure constraints push teams to make trade-offs between flexibility and robustness. Without cross-discipline collaboration, those trade-offs derail the design.

- ECAD-MCAD Integration: Turn electronic and mechanical collaboration challenges into a competitive advantage by seamlessly working across domains without losing intent or time. Bi-directional data transfer between your ECAD and MCAD tools makes it easy to collaborate with your mechanical team and share design revisions as they happen.

- Time Efficiency: Reduce design delays and bottlenecks when teams export, share, and import CAD files. Seamless ECAD-MCAD collaboration cuts development time, minimizes design responses, and accelerates time to market.

ECAD-MCAD Integration – Complete product visualization in Multi-board Assembly

Challenge 4: Managing Design Complexity, BOM Accuracy, and Manufacturing Documentation

Miniaturized, feature-rich products demand compact, intricate cable harnesses. As harness complexity grows, so does the potential for routing mistakes, overlooked electrical needs, and contradictory mechanical constraints. Maintaining an accurate Bill of Materials (BOM) and robust documentation through these changes proves difficult.

The Altium Advantage

- Simplified Complex Designs: Altium streamlines intricate cable harness designs with efficient layout routing and real-time validation, making the process faster and more accurate.

- Seamless BOM and Documentation Management: Automatically update the Bill of Materials (BOM) and generate precise manufacturing documentation, ensuring smooth production and collaboration.

Manufacturing Documentation – Ensure accuracy and readiness for production

Challenge 5: Collaboration - Bridging the Gap Between OEMs and Manufacturers

Design success depends on fluid collaboration between OEMs and manufacturers. OEMs emphasize integration and compliance, while manufacturers prioritize scalability and cost control. Gaps in communication and poorly coordinated revisions can also derail production.

The Altium Advantage

- Enhanced Collaboration: Altium enables better collaboration by providing a unified real-time environment for OEMs and manufacturers.

- Cloud-Based Data Sharing: Teams can instantly share harness schematics, layouts, and BOMs, reducing miscommunication.

- Live Commenting: This feature enables manufacturers to provide feedback directly within the design, ensuring changes are tracked and aligned.

By leveraging Altium, OEMs and manufacturers can streamline communication, accelerate design validation, and reduce production risks, ultimately leading to a more efficient and cost-effective cable harness design process.

Collaborative Design – Streamline feedback and teamwork in real time

Where Altium Bridges Functionality and Manufacturability

Designing cable harnesses demands coordination across PCBs, disciplines, and teams. The main hurdles include managing multi-board systems, maintaining synchronization during revisions, merging ECAD and MCAD requirements, controlling complexity, and ensuring collaborative design execution.

ltium's suite of tools equips engineers to meet each of these challenges head-on. With integrated features that reduce friction, minimize rework, and promote real-time collaboration, Altium accelerates harness design and improves product readiness.

Ready to build accurate, efficient cable harnesses for complex systems? Explore how Altium Develop simplifies multi-board interconnection without sacrificing performance or manufacturability.