How 3D Printing & AI Are Reshaping Wire Harness Prototyping

3D printing and artificial intelligence (AI) are rapidly transforming wire harness design and production. These innovations reduce prototyping timelines, increase design precision, and lower costs, all while refining how engineers approach complex harness development and manufacturing.

The Role of 3D Printing in Wire Harness Prototyping

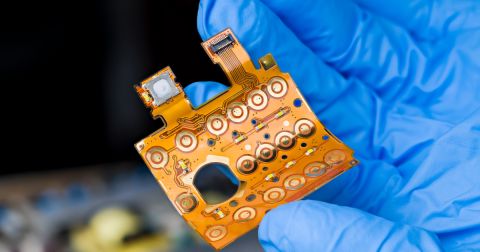

3D printing has emerged as a pivotal tool in wire harness prototyping, replacing slow, expensive traditional methods with a faster, more flexible approach. Engineers now print physical prototypes with intricate geometries and high precision—eliminating the need for molds and long lead times.

1. Accelerated Iteration and Testing

Legacy prototyping methods often required weeks or months to build physical models. In contrast, 3D printing enables near-immediate iteration. Engineers can print and test functional harness prototypes, adjust designs, and reprint updated models within hours.

A printed prototype might include routing guides, brackets, or enclosures, while the wiring and connectors are manually integrated. If issues surface during testing, the team can modify the CAD model, reprint the component, and resume evaluation without starting from scratch.

2. Complex Geometries and Tailored Designs

Modern vehicles and electronic systems demand compact harnesses that conform to tight, non-linear spaces. 3D printing supports this complexity, enabling custom components that align with the form factor of specific devices.

For example, in electric vehicles (EVs), where space optimization is at a premium, engineers use 3D printing to produce harnesses that maximize efficiency without compromising fit or function. This approach reduces reliance on high-volume tooling and minimizes unused inventory.

3. Streamlined Validation and Pre-Production Testing

3D printing simplifies performance evaluation. Engineers print working harness models, validate mechanical fit, and run physical tests, including routing checks and enclosure integration, before investing in mass production. Advanced simulations assess thermal performance, flexibility, and vibration resistance, guiding design refinements before physical testing begins.

4. Cost-Effective Low-Volume Manufacturing

Beyond prototyping, 3D printing also supports low-volume production. Instead of investing in expensive tooling, manufacturers can print limited runs of specialized harness components. This proves ideal for experimental builds or niche models.

For instance, a prototype EV may require custom enclosures or unique connector housings not available off-the-shelf. 3D printers can deliver bespoke components on demand, accelerating the shift from prototype to production.

AI: Automating & Optimizing Wire Harness Design

While 3D printing accelerates physical iteration, AI revolutionizes the digital process by automating complex tasks, refining layouts, and predicting failure points with greater accuracy.

1. AI-Driven Wire Harness Routing & Optimization

AI-powered design tools evaluate countless routing possibilities across a vehicle’s structure, identifying the most efficient cable paths while minimizing material use and mechanical stress. These tools also predict EMI risks, thermal load distribution, and stress concentrations, allowing engineers to preempt design flaws.

2. Automation of Manual Design Workflows

Tasks like wire length calculation, connector placement, and compliance verification consume time and introduce opportunities for error. AI streamlines these operations by automating routine steps and freeing engineers to focus on critical decisions.

For example, AI algorithms can analyze performance parameters and recommend connector locations that balance durability with spatial efficiency.

3. AI-Powered Predictive Simulation & Virtual Testing

AI simulates real-world stressors like vibration, thermal cycling, and electromagnetic interference. These simulations reduce the need for extensive physical testing, cut development costs, and identify structural or electrical weaknesses early in the process.

Manufacturers use these insights to model lifespan, anticipate failures, and avoid costly redesigns.

Companies Driving Innovation in 3D Printing for Wire Harnesses

Several companies now lead the way in combining AI and 3D printing for wire harness applications:

-

Q5D: Q5D specializes in robotic 3D printing and automated wire laying, enabling manufacturers to directly print conductive paths onto 3D surfaces. Their technology is helping to eliminate traditional wire harness assembly, making the process faster and more cost-efficient.

-

TE Connectivity: TE Connectivity uses 3D printing (through their 3D4P process) to speed up wire harness prototyping and make designs more customizable. They quickly create parts like connectors and clamps, which saves time and money compared to traditional methods. Their 3D Printing and Prototyping Center in Pennsylvania uses different 3D printing technologies to produce parts fast. They also use HarnWare software, which helps engineers design wire harnesses in 3D and test them before production. This combination of 3D printing and software makes the process faster, cheaper, and more flexible.

-

MasterGraphics: MasterGraphics offers 3D printing solutions for the wire harness industry, using digital light processing (DLP) printers to produce low-volume electrical connectors. Their rapid prototyping capabilities make it easy to iterate on designs, providing flexibility in customizing wire harness components.

-

Makenica: Makenica leverages 3D printing for custom wire harness connectors in the automotive, aerospace, and healthcare industries. Their additive manufacturing approach optimizes connector designs for weight reduction, performance efficiency, and reliability, making them a key player in advancing wire harness prototyping.

-

Meridian Cable Assemblies: Meridian Cable Assemblies integrates 3D printing technologies like the Fuse 1 to produce wire harness components such as connectors and fixtures. These technologies allow them to quickly create complex parts, cutting lead times and improving prototyping efficiency.

The Future of Wire Harness Prototyping: Where AI & 3D Printing Converge

The convergence of 3D printing and AI continues to reshape wire harness engineering. These technologies coexist and integrate into a single workflow that accelerates design, reduces error, and ensures long-term reliability.

Expect to see:

- AI handling full end-to-end harness design workflows

- On-demand 3D-printed harness components for rapid deployment

- AI-based predictive maintenance detecting issues before failure

Together, these capabilities enable teams to move from concept to final product with greater confidence and efficiency.

Engineering the Next Generation of Harness Systems

AI and 3D printing already define the future of wire harness prototyping and production. By investing in these tools now, engineering teams can improve iteration speed, reduce development costs, and produce higher-performing systems.

Wire harness design no longer depends on outdated methods. With intelligent software and agile manufacturing, teams can move faster, build smarter, and stay competitive.

The next generation of wire harness engineering has already arrived. Are you ready to lead it?

Experience the power of wire harness design in Altium Develop.