Your PCB Layout Checklist: What’s The Difference Between DRCs & MRCs?

When you're working your way through a complex PCB layout, there is a large number of important design features to keep track of. Will it be high speed? What about the vias and solder mask? Your PCB layout can be quite complex, and your layout will have to conform to multiple design guidelines to ensure it will function properly once manufactured. Your layout will have to go through multiple design rule checks (DRCs) to spot electrical errors and manufacturing rule checks (MRCs) to spot DFM errors. All these points should be put into a PCB layout check design rules and should be examined at multiple points when creating the layout.

So how can you ensure you've checked everything on your PCB layout checklist? Today's ECAD applications play an important role in helping you follow important design rules and check that you've passed a design rule check and MRCs. When you need to ensure your circuit board complies with important electrical design rules and DFM rules, there are some simple utilities in your ECAD software that can help.

PCB Layout Checklist

If you try to write out a complete list of DRCs and MRCs, you'll easily fill up a sheet of paper and you'll probably still forget a few points. Some common DRCs and MRCs that most designers can follow on instinct are:

- Conductor-to-conductor clearances

- Trace width for current requirements and controlled impedance

- Minimum via and hole sizes

Obviously, there is much more than feature sizes and clearances that need to be followed in a PCB layout. I once read a PCB layout checklist that included over 40 items that needed to be checked, and these should be checked at multiple points in the design. No one can keep track of all of these rules, let alone check them at multiple points in the design.

Modern ECAD tools continue to add more of these design and DFM rules to DRC/MRC routines. Usually, these rules are are accessible in a single menu and are broken up into separate categories for convenience. Your PCB design application basically creates a PCB layout checklist for you and lets you run DRCs/MRCs on-demand.

Need to Run DRCs? Use Online DRCs Instead

While it's nice to be able to run DRCs/MRCs on-demand, running these checks sporadically creates a number of risks that can force a redesign. These risks can fall in the domain of your electrical layout, manufacturing, or both. Historically, PCB designers would run DRCs in their ECAD software, then they would give the design to a manufacturer, who would run MRCs in more specialized software. This workflow puts you at risk of:

- Inefficiency: Everytime a problem is spotted after running manual DRCs, the designer has to go back and make potentially large changes to the PCB layout. Running DRCs sporadically increases the extent of any redesigns.

- Low yield and reliability: MRCs are meant to catch manufacturing errors that affect reliability and yield, as well as the ability to manufacture the design. When a design doesn't pass MRCs, it might get sent back to the designer for changes.

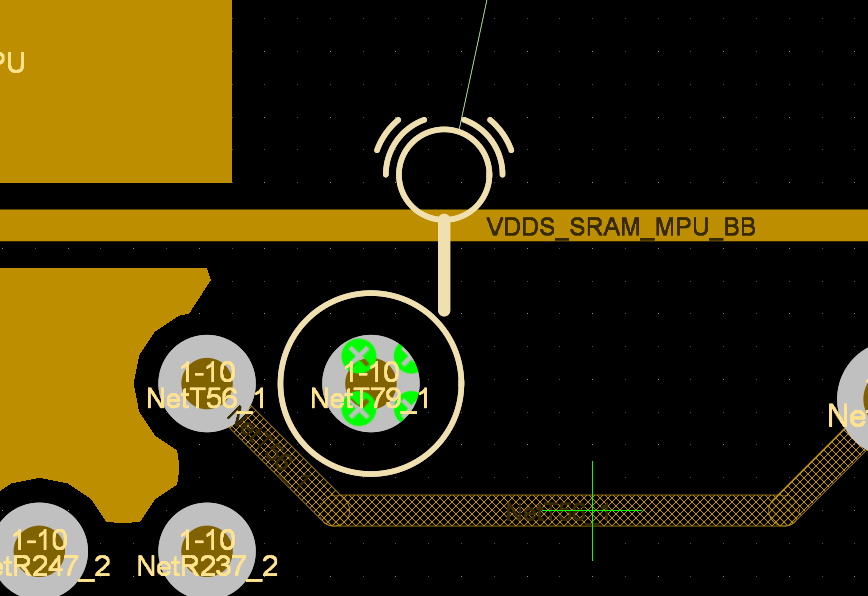

Instead of running DRCs and MRCs in separate programs, and instead of running them sporadically, you need an online DRC engine that checks every item in a PCB layout checklist within a single program. I said at the beginning there is a difference between DRCs and MRCs, but today's CAD tools just lump electrical and DFM rules into a single set of design rules. As you place components, route traces, and make other changes to your design, an online DRC engine will flag the user visually whenever there is a design rule violation. The designer can see an electrical error or DFM error as soon as it is made, rather than running DRCs after a large number of errors accumulate in the PCB layout.

Once the error is flagged, a designer can instantly make changes to the layout and resolve the error. In the above example, we have a collision error on a different layer where the highlighted via passes through an existing trace and flags a design rule error. The designer can watch rules get resolved as changes are made in the layout, as shown below.

When you use the best PCB design software, like Altium Designer, you'll have access to powerful layout and routing tools that include an online DRC engine. These design rule checks will happen as you place components, route traces, and make other changes to a design. These tools help you stay productive and deliver a clean design to your manufacturer the first time.

Would you like to find out more about how Altium can help your next printed circuit board design with its advanced online DRC engine? Talk to an expert at Altium.