Top Issues in PCB Data Management Systems and Processes

PCB Data Management is a journey with no final destination. On this journey, significant issues can and often pop up. If you decide to ignore them, they can worsen and ultimately lead to completely ruining your PCB data management systems and processes.

In this blog, we will look at several of these issues. I prefer to call them pitfalls because they can appear suddenly, and you can easily fall into them if you’re not careful. But, if you are aware of them, half the battle is won.

Too Many Chefs in the Kitchen

One of the more common issues with almost every PCB Data Management system is allowing too many chefs in the kitchen. Meaning that everyone is permitted to do certain things. Companies often do this for the sake of either expediency or availability, but it is a terrible mistake.

I believe that the librarian performs an essential role in the PCB design process. The very foundation for every PCB Design are the components, and the quality of those components falls solely on the shoulders of the librarian.

I recently had this experience when the “decision was made” to allow everyone to create components in the library. We were talking about a group of around 40 people. It was not long before we quickly began to lose control of the entire library because of incorrect parts.

The solution is to control which individuals have access and what they can do. Once we select our few librarians, we quickly had control over component creation, significantly increasing the quality.

Rogue Libraries

Another huge PCB Data Management issue, and I would add to a company, is the proliferation and use of Rogue Libraries. As the name implies, rogue libraries are outside of the controlled PCB Data Management System. They usually contain components which are not reviewed and are flat out wrong. For various reasons, designers have and use them. However, they also risk the PCB Design failing. I have seen multiple problems, caught only in Fabrication and assembly, which came from bad Rogue Library components.

We regularly check each design using the Item Manager in Altium Designer to verify the source of each component. When we see that an uncontrolled library was used, we handle it immediately to get rid of them.

The solution to that particular issue is a simple one. Don’t allow Rogue Libraries under any conditions.

Quality Assurance of information

A PCB Data Management system represents one thing to a company: money. The big question is on what side of the accounting ledger will it fall? The information can either be a profit or a loss. That all depends on the quality of the data. I don’t know which is worse; a Rogue Library used on a PCB Design or unmanaged components? They both have the same results. The producing of a bad PCB Design and wasting of that money.

Review Process

What we need is a detailed plan in place to review an overall component and its parts. Since Models, such as the Schematic Symbol, Footprint, 3D Models and Simulations, make up the overall components, problems with any of these models will impact multiple parts. When reviewing, I concentrate on these models much more because of that reason.

This model review process is a part of the overall review of a component before we release it. We usually quarantine those components for review, so they do not mistakenly slip in and ruin a design.

Administrating Changes

One thing that is guaranteed when working with PCB Designs is that it will change. How you identify, implement, and verify those changes is a vital issue. You must specify between the Static vs. Dynamic information knowing that the specific data will probably change. Then, we use an audit process to identify those changes.

When you finalize those changes, the lifecycle state of the component reverts back to “New” to send it back through the Review process to make sure you correctly implemented the changes.

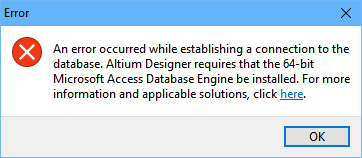

Not using the correct Software

The biggest problem by far is having everything you need for a successful PCB Data Management System and a substandard software package that falls far short of your needs. To accomplish your objectives, you must select not just the right software package but rather an excellent one. The best that I have seen has been Altium Designer®. The various software packages are flexible to tailor for your particular company needs. This is the most crucial point of this blog. You can have the best plans, organization, managed data, but if your software cannot keep up. What is the point?

I have seen companies operate from where they are at but never consider where they will be. That is the most significant benefit of working with a company like Altium. They have a partnership with the PCB Designers, which has a single goal; that we are successful.

Conclusion

I hope you are starting to see that PCB design is not a straightforward process. There are so many problems and issues that come up and must be considered to make sure your PCB design is a success. Knowing those significant problems and being proactive about avoiding them will help you tremendously.

Recently I was asked what advice I would give to new PCB designers. I knew right away what that would be “Never stop learning”. There is always something more to learn in this business. Fortunately, we have some of the most significant training resources available to us — one of the best being Altium itself.

Would you like to find out more about how Altium Designer can help you avoid the top process issues in PCB data management? Call an expert at Altium.