Escape the Pain of a Gerber Files Viewer and Invest in a 3D PCB Editor

As the design of printed circuit boards grows more challenging with flex, rigid-flex, RF, and other technologies, it is becoming more important than ever to be able to see exactly what it is that you are designing. Then compounded by shorter design cycles and fewer prototype builds the need for full verification of the design before manufacturing has become a necessity. Thankfully PCB design tools have kept pace with different ways to view and verify your final Gerber files with 3D PCB editors.

There are several options now to be able to view your design in 3D while you are still in layout. This can be an enormous benefit to your PCB design team as long as you are using layout tools that truly let you interact with your design in 3D. Some tools, however, may advertise that they have the 3D capability, but fall short of giving you the full functionality that can really help you. Here are some of the things to consider in the world of 3D PCB design, answer what is 3d viewer and do I need it.

The Painful Difference Between Gerber File Viewers and 3D PCB Editor Systems

There are still many PCB design systems that do not offer any sort of Gerber to 3D model environment for their design. In order to do any kind of 3D checking with these systems, you need to be able to rely on the traditional 2½ D component height values that PCB design systems have used for years. This will give you a maximum height value, but it won’t reflect component or mechanical obstruction contours accurately. This limits your ability to do an accurate 3D check of your component placement and ultimately hampers your Gerber data capabilities.

There are viewers that can be used to see how your layout will look in 3D, but instead of relying on industry-standard models for 3D accuracy, they will use the 2½ D information from your layout system. Again this will leave you with a less-than-accurate picture of what your layout will truly look like once it is actually assembled. Without the ability to see your layout in 3D, you really must rely on prototype builds to get an accurate idea of what your component placement will look like.

There are also some systems that advertise that they have Gerber file to 3D model capability, but in reality that 3D view isn’t any better than aftermarket viewers. These systems are using the same 2½ D data from your design system to create a 3D view of your design. Systems like this usually don’t allow you to interact with your layout in 3D either. They really are just viewers and any layout or verification work that needs to be done will have to be done in the regular 2D layout.

Viewing and editing your component placement in 3D is a real benefit

The Additional Pain of Working with Design Systems that Don’t Offer a Full 3D Solution

There are also PCB design tools that offer 3D as part of their layout system, but their 3D isn’t completely integrated with the overall design system. Working with systems like these usually requires that you push your layout from 2D into 3D through some sort of creation or update process. Although this process will work, it will require more manual intervention on your part in order to demonstrate components and component placement during layout.

The disadvantage here is that you may have some functionality that only works in 2D as opposed to 3D. For instance, some of these tools will allow you to move a part in the 3D environment, but won’t allow you to undo a process unless you go back to 2D. The functionality in 3D shouldn’t be any different than the same functionality in 2D.

Full 3D is important for working with multi-assemblies of system boards too

Full 3D PCB Design Systems will Provide the Solution You Need

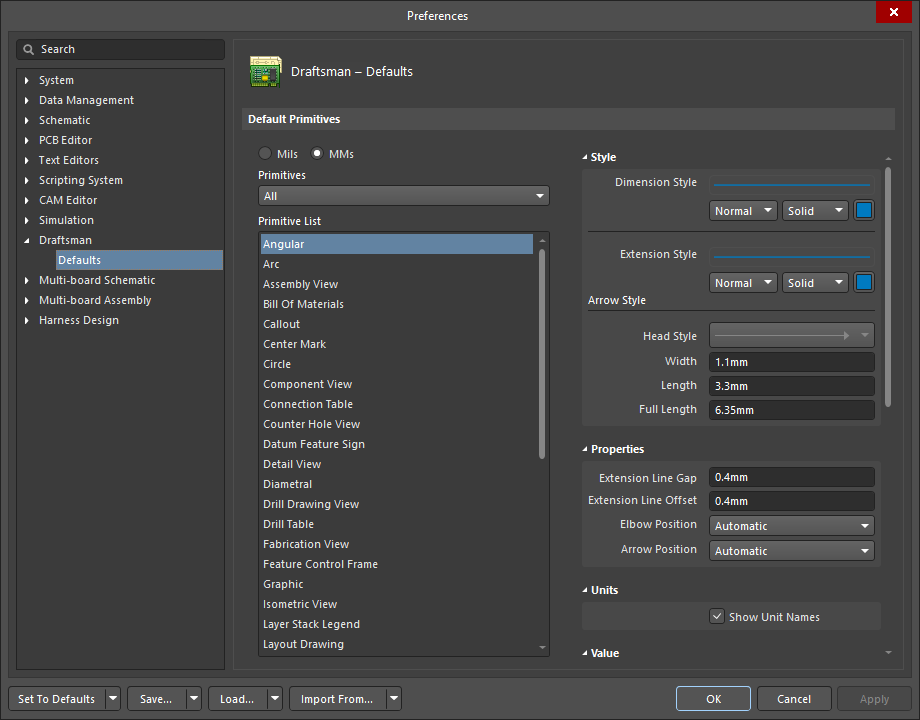

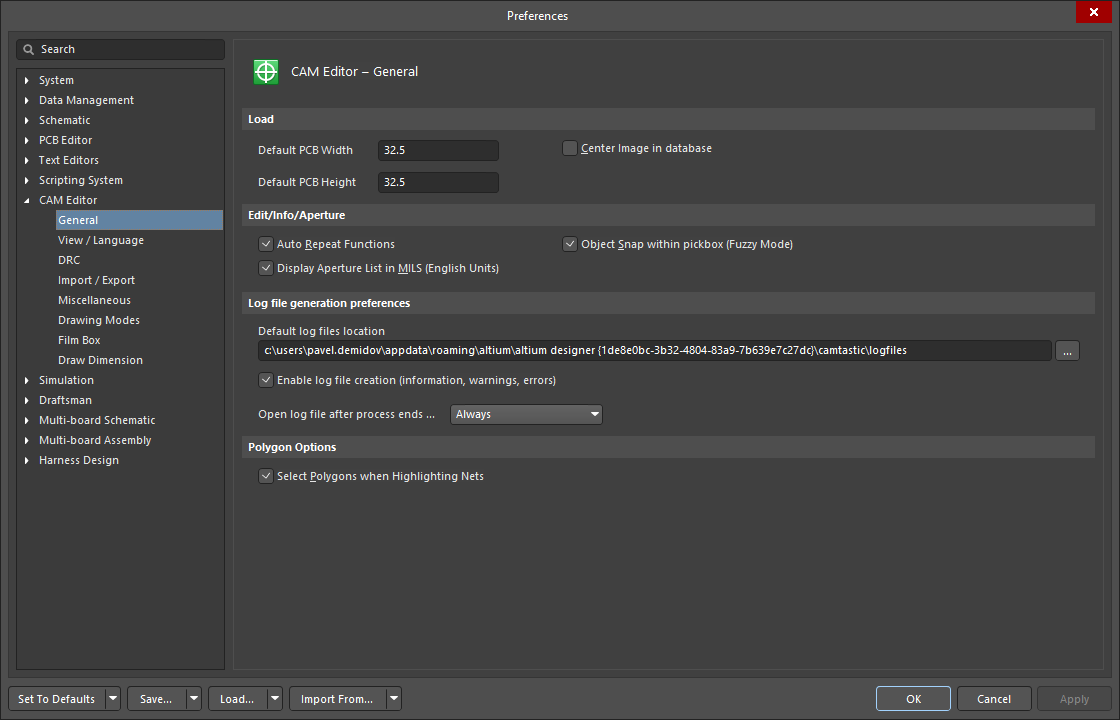

The best 3D PCB layout CAD tools will switch easily from 2D to 3D without any effort other than pushing a button. There shouldn’t be a need to convert, translate, or update the database to move from one environment to the other. Additionally, the functionality that is offered to you in 3D should mirror the same functions on the 2D side as well. If you are moving in 3D it should work the same as it does in the 2D environment and not be a different set of commands.

For our designs, we have settled on using Altium ® to give us the design environment that works best for our needs. We can easily switch between 2D and 3D by pushing a “2” or a “3.” Moving in either 2D or 3D is simple. Altium also allows us to import mechanical enclosures to verify in 3D view Altium that our component placement will work the way it is intended in the final system.

Additionally, we use Altium to import multiple PCB designs from the same system. This way we can verify the form, fit, and connectivity of all system boards in 3D to the full system enclosure. With a smart PCB editor, you can ensure that your design moves forward from component placement and schematic capture to product development and PCB manufacturing with the utmost security in its accurate assembly.

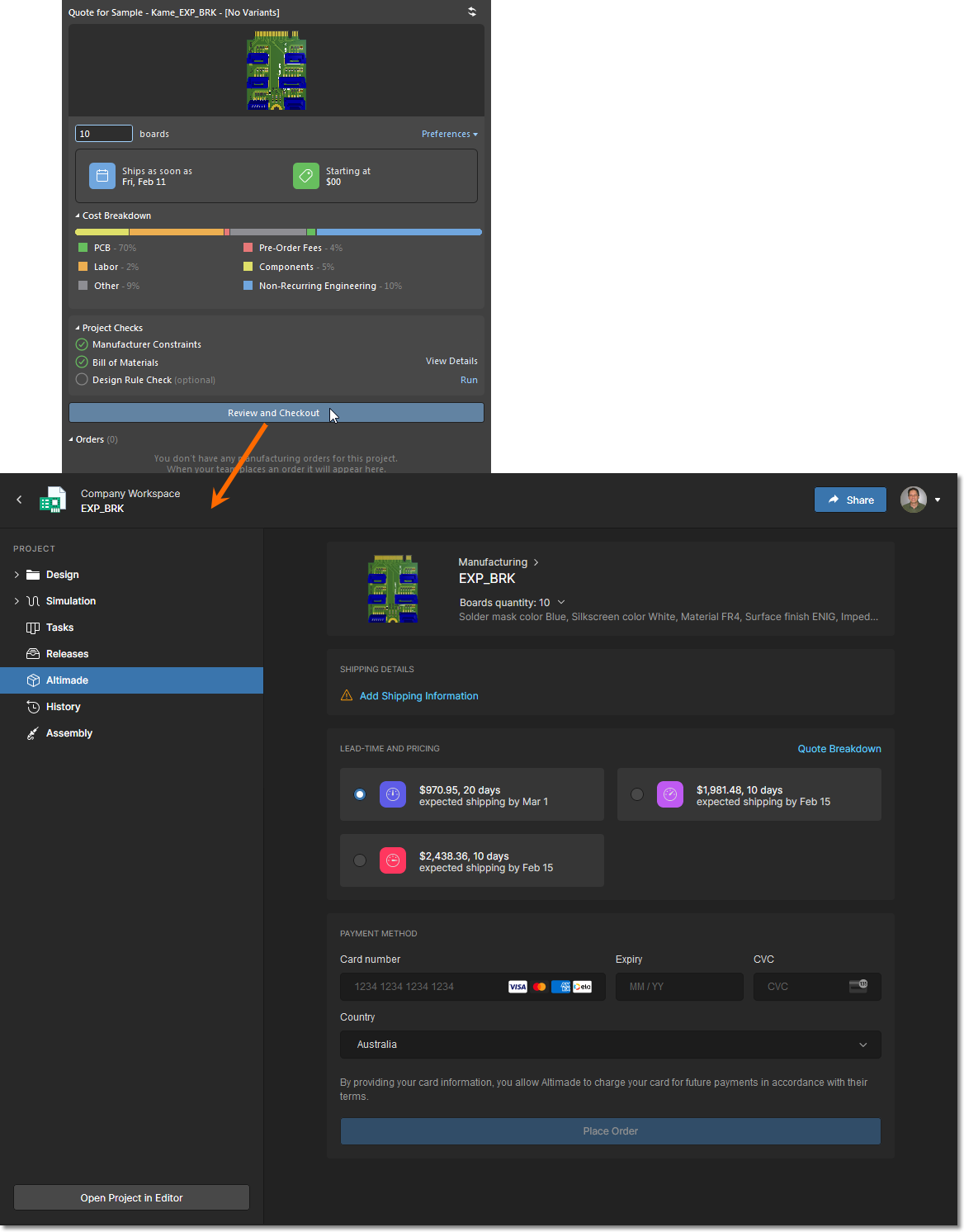

Altium is a full-featured PCB design software system with schematic capture, simulation, layout, auto-routing, multi-board assemblies, and many other tools and capabilities as well. You will find out as we did that using Altium’s 3D engine for placement verification and alterations is a real benefit to our design department schedules and budgets.

Would you like to find out more about how Altium can help you to work with your next PCB design placement Gerber to 3D model? Talk to an expert at Altium.

Start the journey to switch over to Altium Designer today.

“We were using OrCad and switched to Altium for improved functionality, better capture/layout/database integration, ease of use, and team design support. The price point is attractive and really the Altium package is impressive at any price point.

We do rapid prototyping so we need a package that is easy to learn and use, seamlessly integrated, supports team design and handles documentation and version control with minimal manual overhead so we can get projects completed on short timelines. Altium provides all of this and at a reasonable price.”Todd Cicchi,

Manager/engineer - Photonics at Coriant