Bill Brooks Accelerates Design-based Over Tool-based Curriculum

Judy Warner: How long have you been designing PCBs and what led you to the profession?

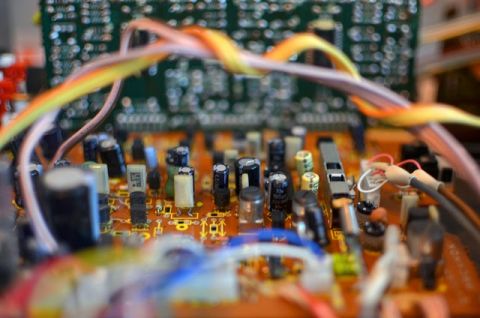

Bill Brooks: I’ve been designing boards since about 1970. My father introduced me to electronics. He was an aerospace professional working in R&D at Hughes Aircraft Company, UCSD, and later at Aerospace Incorporated. He decided to open up a printed circuit shop out of our garage in Vista, CA while I was still in junior high school. In 1969 he taught my brothers and me all of the processes involved in making printed circuits. He introduced me to printed circuit layout with a schematic I chose from the Texas Instruments Datebooks for a 10 watt solid state transistor-based audio amplifier. I planned out the circuit using colored pencils on vellum and then did the artwork on a light table using Bishop Graphics die cut tape and patterns on 7 mil Mylar for ICs and then did the photo reduction of the 2:1 scale artwork with some orthographic film on our process camera to create the working photo masters. I prepared the copper clad material by cleaning it and coating it with photoresist and then exposed it to UV light using those films that had been registered and pin-punched and then developed the image in a vacuum frame to prepare it to be etched. After etching, I drilled it and coated it with solder and then trimmed the board to size. Then I gathered the components and assembled the board and checked my work and then powered it up and tested it...and it worked!

I took electronics classes in summer school and learned to build my own tube-based superheterodyne radio and a 400 watt DC Power supply. We worked with ferric chloride as an etchant in that class to make a printed circuit as well, although it was more primitive than the process we used in my dad’s shop. I did an electronic metronome as my science fair project that year.

Eventually my dad closed his shop and I began working for other companies as a Draftsman®. Schematics, fabrication drawings, and printed circuit artworks became my livelihood for a while. From there I became a technician, then finally began doing layout. I also did some mechanical design and packaging of electronic circuits for a few companies as a temporary employee. During that time I worked for dozens of companies, several with recognizable names such as Teledyne, SAIC, and Hughes Aircraft.

I have been involved with the IPC Designers Council since about 2000. I taught PCB design classes at Palomar College in San Marcos, CA over about a 10-year period and wrote for PCB Design Magazine.

Warner: Since you have a long history in layout, what do you think is a young designer's greatest challenge today?

Brooks: There are many challenges faced by new designers. One of the greatest challenges is finding a valuable source to teach them how to do board designs that are reliable, cost-effective, easy to assemble, easy to test, functional, and can meet all of the agency approvals needed to get a product to market or meet their customers’, consumer, commercial, industrial, military or medical requirements.

Warner: What kind of board complexity do you design today, and where do you think EDA technology is headed (or should be headed)?

Brooks: The boards I do today can be reasonably complex. Some are flex circuits and some are rigid circuits. The environmental and reliability requirements are fairly extreme: high vibration, EMI/EMC requirements, environmental testing, HALT/HAST, and EMI testing is done on all of our board assemblies. Our customers expect their equipment to be long-lived. Ten years of operation is not uncommon to see a machine in service. There is a mix of analog and digital circuitry, specialized machine interfaces, robotic control of machine operations, conveyorized machine processes, power efficiency and low emissions of electromagnetic radiation or interference. We have a mix of communications protocols to deal with, including fiber optic communication as well… typically our boards have differential pair requirements.

EDA needs to integrate good tools to tackle the difficult designs like RF and microwave design, high-speed digital communications, flex circuits, mechanical interfaces, multi-board assemblies, tolerances and derating, vibration analysis, EMI/EMC requirements, and Safety Agency and regulatory agency issues. Expert systems should guide designers to make informed and intelligent decisions about their designs to save the users money, time and effort, and help them avoid making costly mistakes.

Warner: If you could only give three practical pieces of advice to a less experienced designer, what would they be?

Brooks:

- Learn as much as you can and get certified through the IPC CID courses. Knowledge of electronics, manufacturing, mechanical design, and drafting standards is key.

- Ask your employer to let you attend PCB West and other training venues to get more training in specific aspects of design. Learn about equipment safety, reliability, testability, manufacturability, EMI/EMC, proper shielding, bypass caps and their use, etc.

- Get involved in the local user group organizations that support your CAD tool.

Warner: Bill, you’ve been passionate about teaching designers over the years. Please share about your tenure at Palomar College teaching PCB design, and where is that program today?

Brooks: When I took over the program it was using PADS PCB as the platform. It was in place for a number of years with a few different instructors at the helm. I tried to change the program from a ‘tool-based’ curriculum to a ‘design-based’ curriculum. I wanted the students to learn more about design so that they would not just be trained in the use of the tool. The administration was wooed by Mentor Graphics to use their new Expedition Software to teach board design as an upgrade from PADS, but we had a lot of trouble with it and it became too unreliable as a learning tool because of the tool interface idiosyncrasies, and structured input requirements made it impossible for beginners to learn the tool rapidly enough to really begin to learn design principles. I recommended a change to Altium Designer® as the tool for the class because of its ease of use and user interface, and once we had an agreement, things got a lot easier for us to progress past tool training so we could focus more on the design training as opposed to spending all our time just trying to get the tool to do what we needed. Funding and attendance issues and administrative bias seemed to create some headaches for us. After I left they got someone else to teach the program. I think they are looking for someone else to keep the program alive today. The students were from all walks of life, some exceptional, others were very challenged, but we managed to get quite a few students out there trained to layout boards.

Warner: Some compare PCB design to art. Since you are a talented sculptor, do you agree or disagree, and why?

Brooks: There is an aspect to PCB design that to me seems artistic in nature. An artist senses things like symmetry, economy of space, patterns, and paths through a pattern, and this is true also of a designer. I think almost every good designer I have known has had some interest in art, whether they are painting, drawing, sculpting, photographers, or musicians. PCB design is not just a left brain technical challenge, it’s also physical, aesthetic, and has aspects of human engineering as well as ease of use and functionality. A good designer needs good visualization skills. We didn’t have the advantage of seeing our components in 3D before 2006. When Altium Designer added that feature it revolutionized the way designers can work. All the other CAD companies followed suit once they could see what a tremendous advantage it was to be able to see the mechanical relationships between the board designs and the environment they were being installed into. Design tools have come a long way since I was doing tape-ups!

Warner: They certainly have! Thank you very much for sharing your rich history in PCB design, teaching design and all you’ve contributed to the industry.

Brooks: It’s been my pleasure, Judy. This career has certainly been a fun ride!