PCB Design

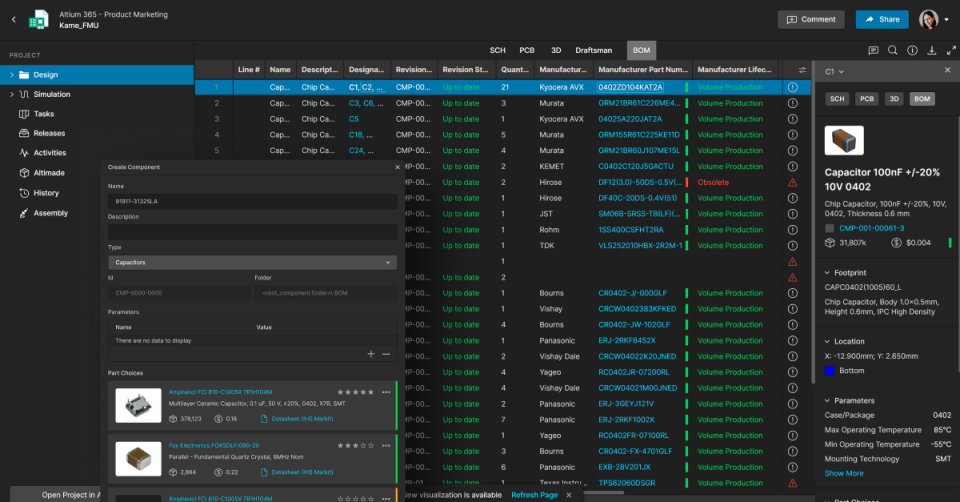

Read the latest PCB Design information from the industry's leading experts. Altium is paving the way for enhanced engineering by designing the next generation of tools unifying the PCB design industry. Our resources are meant for everyone, so if you are a beginner learning what is a PCB, seeking advanced solutions for getting component data in real-time while designing a board and collaborating across design teams, or wanting to listen to interviews with industry pioneers, we have you covered. If you haven't already, we encourage you to get familiar with the best PCB Design software, Altium Designer, and Altium 365, our electronics product design platform that unites PCB design, MCAD, data management, and teamwork!

Live Webinars

See what upcoming live webinars we have scheduled and join us for one!

On-Demand Webinars

Missed our live stream webinar? Watch all of Altium's on-demand webinars here.