Redefining the Assembly Process for Miniaturization and Ultra HDI Technology

Staying ahead in electronics assembly means embracing innovation and redefining standard processes. Seven years ago, the SMTA Test Board was introduced as a groundbreaking solder paste testing tool, addressing the challenges posed by the accelerating trend of electronics miniaturization. We embark on a journey to revamp and enhance this test board and invite you to stay tuned for the upcoming ebook, with each chapter being a part of the story of "Evolving Excellence."

Why Migrate to Ultra HDI?

The need for evolution is undeniable. The landscape of electronic components has transformed, with miniaturization reaching unprecedented levels. As we jump into this redesign process, the spotlight is on Ultra High-Density Interconnect (UHDI) technology. This cutting-edge approach aligns with current industry trends and anticipates the future demands of electronics manufacturing.

Ultra HDI presents a paradigm shift, pushing the boundaries of what's possible in PCB design, fabrication, and assembly. As electronic devices shrink in size and demand for higher performance rises, traditional methods no longer suffice. The migration to Ultra HDI is not just an upgrade; it's a strategic move to accommodate finer pitches, tighter spaces, and advanced assembly techniques.

The ebook will chronicle the journey of incorporating miniaturization and Ultra HDI into the SMTA solder paste testing tool. From concept to realization, each chapter will unveil the challenges, breakthroughs, and innovations that define this transformative process.

Meet the Key Contributors

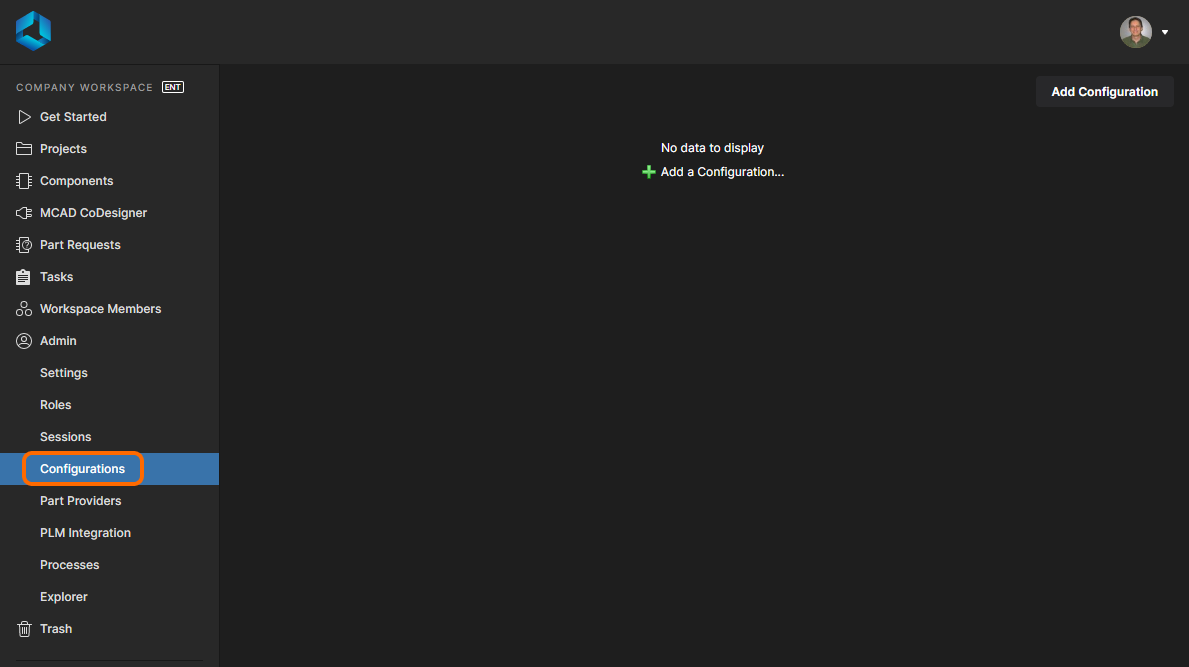

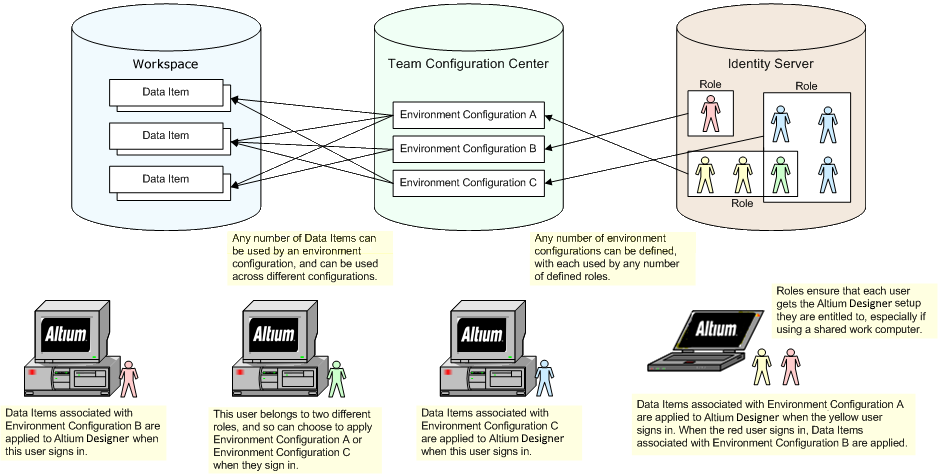

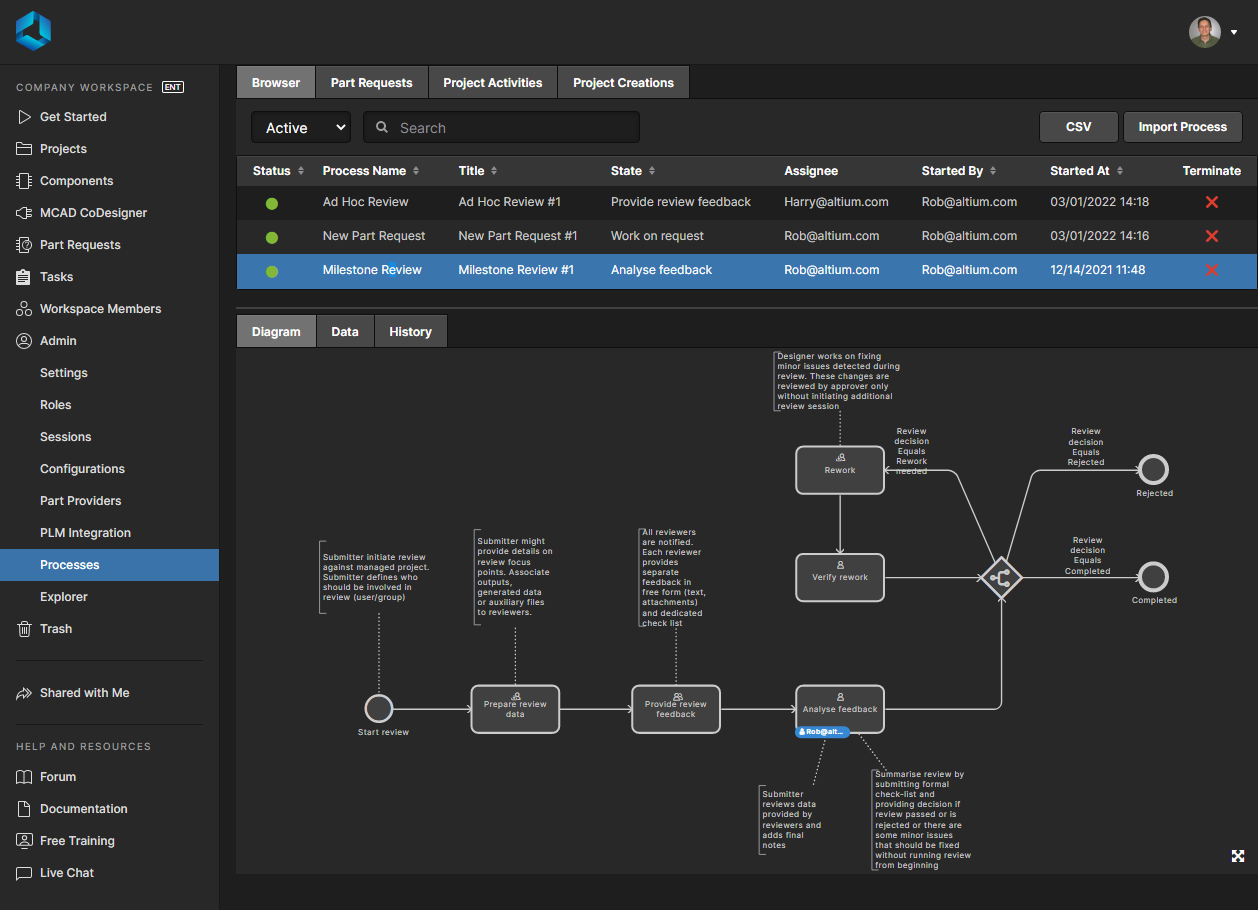

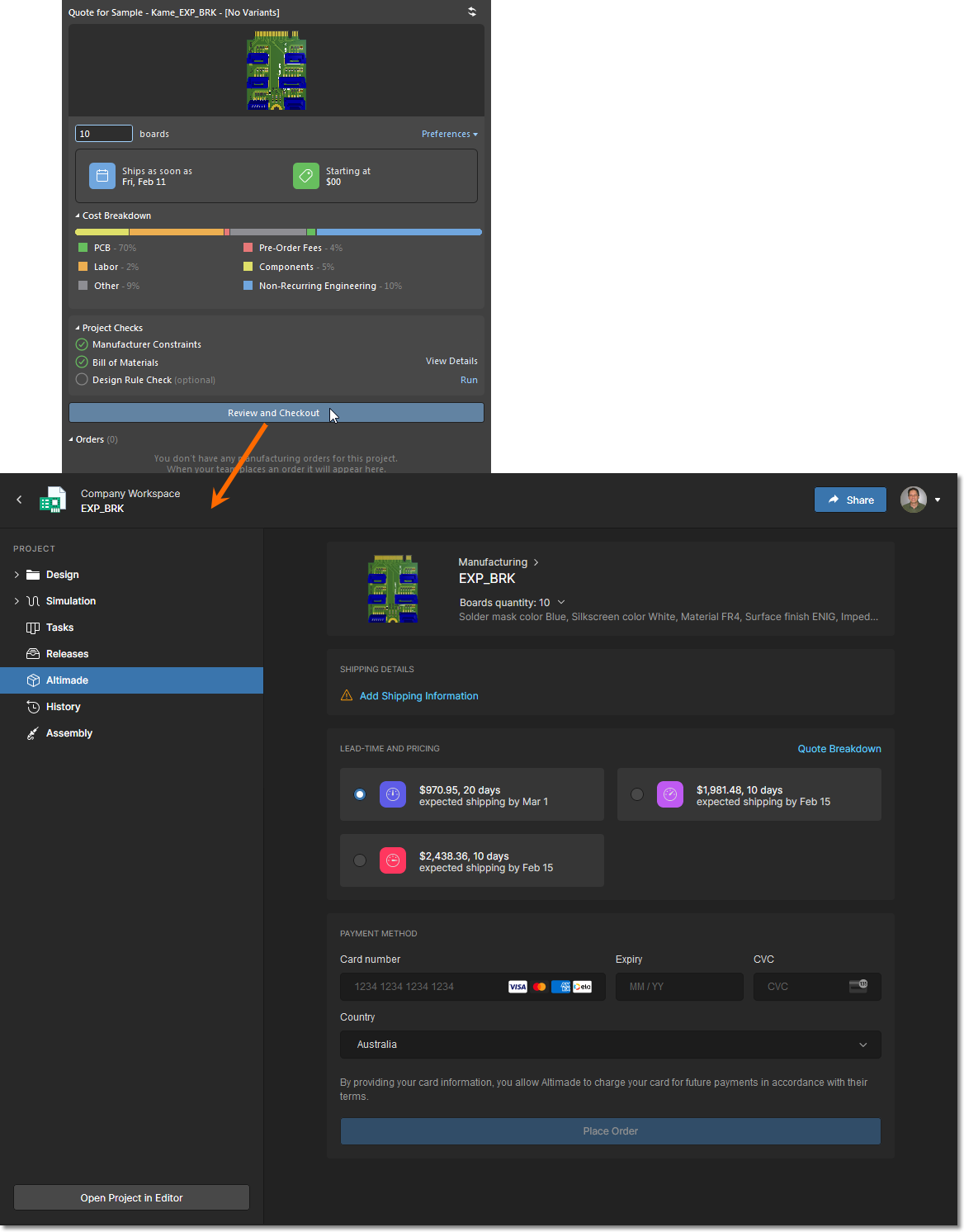

- Altium 365 Innovation: Altium 365 supports this project’s development collaboration. When completed, the board will serve as a reference design with the Altium 365 Embedded Viewer. Explore the synergy of the Altium 365 electronics development platform as we push the boundaries of innovation in electronic component testing. Witness how the latest features enhance the design process for ultra-miniaturized components.

- Shea Engineering's Expertise: Delve into the engineering brilliance of Shea Engineering, the driving force behind the assembly process. Chrys Shea has been designing tests and test boards for new assembly processes for over 35 years. Learn the strategies employed to seamlessly integrate numerous tests into efficient evaluations that uncover the best and worst characteristics of machines, materials, or processes.

- American Standard Circuits' Precision: Experience precision at its best with American Standard Circuits, the PCB fabricator partner. Discover how their advanced manufacturing techniques bring the redesigned test board to life, meeting the highest standards of quality.

- SMTA's Industry Insight: Gain valuable insights from the Surface Mount Technology Association (SMTA), providing industry perspectives on the evolving landscape of electronics assembly. Understand the implications of miniaturization and UHDI from a broader industry standpoint.

Starting Point

The current test board was developed to address the industry's need for miniaturization–as defined in 2017. As electronics manufacturing continues to evolve, many components and test structures in the existing SMTA test board can be considered mainstream. This new Ultra HDI test board will address industry trends that are emerging now and are expected to be mainstream in the next 2-5 years.

When introducing new technology, SMT assemblers often prefer specialized test PCBs over production products. Test vehicles usually have better availability and lower costs than production boards. The SMTA Miniaturization Test Vehicle (MTV) version 2.1 packs over 20 tests in one design that can be run in less than one shift, making it far more efficient than production boards.

MTV 2.1 was originally designed for solder paste evaluation. Since its introduction, it has also been used to execute a myriad of other SMT tests, including evaluations of stencils and coatings, board supports, squeegees, under wipe solvents and textiles, BTC voiding, 01005 and 008004 assembly processes, 0.4mm BGA capability, and DFM design rules. This design will not be obsoleted, but some of its larger packages will be retired to make room for the next generation of miniaturization on version 3.0. There will still be plenty of utility in the original design for the mainstream PCB assembler, and it will still be available for years.

The updated design will test SMT assembly processes, offer tests for Ultra HDI fabrication capabilities, and incorporate the rapidly emerging considerations of Surface Insulation Resistance (SIR) and Rework.

As with the original test vehicle, only one side will get populated. The unpopulated side will retain the most wetting, spread, slump, coalescence, and Print-to-Fail (PTF) tests. Some of these “standard” tests will see upgrades to challenge Types 5, 6, and 7 solder paste performance and their associated fluxes. The new layout will also contain areas for impedance and resistance tests and a surface UHDI coupon.

Both sides of the new design will incorporate more real-world fabrication and assembly challenges. The assembly arena will have more off-axis placements, footprints to create tombstoning, print patterns to analyze leading edge effects, and SIR tests with glass slides. In the fabrication arena, the design will address the need for feature sizes beyond what is available with subtractive etch processes and test fabricator capability to support feature sizes significantly less than 3 mils.

Let’s Meet!

Be sure to follow along as we chronicle the challenges and decision criteria to develop the new MTV version 3.0 assembly test design for insight into design, fabrication, and assembly and how Altium 365 streamlines communication throughout this critical supply chain.

Also, don’t miss the chance to meet us in person on March 26, 2024 at the Ultra High Density Interconnect (UHDI) Conference. David Haboud, Technical Marketing Engineer at Altium 365, will run a session on communication gaps between industry stakeholders.