Overview of PCB Design Outputs and Manufacturing Files

Before your board can be put into production and prepared for assembly, you have to generate a set of files that assist your manufacturer. These are your PCB design output files, also known as manufacturing files, fabrication data, assembly files, and a host of other names. Fabricators and assemblers will use different sets of output files to produce your PCBA, and the design team will have to generate these before a product can be quoted and put into fabrication.

Before you send your design file off to a manufacturer in an email, make sure to get a list of their required fabrication and assembly files first. If you’re a new designer, take some time to read over the basic PCB manufacturing file extensions below.

The Standard List of PCB Design Output Files

A list of common PCB manufacturing files is shown below. You might not need to generate everything on this list for every manufacturer, but it’s good practice to just create all of them so that you can ensure your device will be producible almost anywhere.

- Fabrication files - File formats used to create stencils for bare-board production include Gerber RS-274-X/X2, X3 or IPC-2581 smart data formats, and ODB++. NC drill files are used to program CNC drilling machines to place drill holes in the bare board.

- Assembly files - The two main files needed for assembly are the bill of materials (BOM) and pick-and-place file. Both are used to match up parts and placement during assembly. The paste mask file used for assembly will be generated with your fabrication files.

- IPC-D-356 netlist - The 356 netlist (most commonly IPC-D-356A format) is used by PCB fabricators as a standardized point-to-point netlist for reading Gerbers. It is required to detect shorts between different nets as this information cannot be determined from a Gerber file. It is also used to identify probe locations for bare-board testing.

- Prints and drawings - Fabrication and assembly drawings are like the blueprints for your design and will contain a wealth of information. Normally you would put this information in a quote form, but creating a fabrication drawing helps ensure fabricators anywhere will understand exactly how you want the board produced.

- STEP files and 3D prints - These two sets of files go together and they give an assembler the ability to clearly see the orientation of some components with non-standard packaging.

- Testpoint report - This file includes a set of nodes that are designated for electrical measurements, either for continuity testing or more specific in-circuit testing.

- Miscellaneous files - There are some miscellaneous files that might be requested by certain manufacturers. These might include your schematics, netlist, mechanical layer photoplot files (e.g., in DXF or Gerber format), or other reports with comments and back drill requirements.

- Binaries and testing documentation - In high volume manufacturing, some products may require on-the-line flashing of binaries and subsequent functional testing to ensure each product that comes out of manufacturing is fully functional. These requirements need to be specified and a test fixture design may need to be supplied to aid automated functional testing.

It Starts With PCB Fabrication Files

Before your design ever makes it into fabrication and assembly, your fabrication files must be sent in for DFM review and quoting. Your fabricator will examine these files to ensure the design is within their capabilities. This is done with more specialized CAM software, which will check your fabrication files for clearances, feature sizes, feature spacing, and any other aspects of the physical design that will present challenges in manufacturing. Gerber files are most commonly used in this stage of the process, but any fabricator should be able to use other standard fabrication file formats (ODB++ or IPC-2581).

Fabrication notes are also important as they provide all the other information used to fabricate a bare PCB. Things like conformal coatings, surface finishes, specific materials to be used (LPI soldermask, etc.), impedance requirements, your stackup layer/material specifications, and much more are specified in your PCB fabrication drawing. Complete and clear fabrication notes will help ensure your design can be produced anywhere.

PCB Assembly Outputs

Your design may also need to be viewed by your assembler to ensure the design can be reliably produced without defects. Your assembly drawing, pick-and-place, and BOM are used to quote the board and to ensure accurate assembly once bare boards and components are received by the assembler. Assembly drawings contain their own set of notes that aid this process and eliminate any ambiguity in manufacturing.

Simple assembly drawings do not contain much information beyond a 2D view of the PCBA. For example, a basic assembly drawigng shows the assembly layers with component outlines, reference designators, and the board outline. Typically, these are shown for the front and back sides (see below).

3D views in assembly drawings are also useful for an assembler to verify the intended look and feel of the completed PCBA, although these are not required. Typically, this will be an isometric or orthographic 3D view which provides perspective on the location and height of the components in the PCB assembly. Not all PCB design software offers support for these drawings in an automated way; the typical workflow is to export a 3D model, use MCAD software to extract a DXF of the 3D view, and then import the 3D view into a drafting tool like AutoCAD to create a PDF drawing. Altium Draftsman bypasses this workflow and creates the 3D view directly from your PCB layout file.

An alternative 3D view is to show the surface layer and side views, as shown below.

In the assembly drawing, we also have important specifications for the PCB assembler. At a high level, these include:

- The relevant qualification standard or quality standard for the assembly (most commonly IPC-A-610)

- Handling instructions or standards, e.g., for ESD protection, storage, and/or packaging

- Soldering requirements, including RoHS requirement or specific solder alloy and type

Some items, such as the application of thermal pads/TIMs, or the use of adhesives or underfills, may be identified as callouts in the assembly drawing. When using a callout, make sure to include a corresponding assembly note which clearly explains the purpose of the callout.

There is sometimes additional data needed for the assembly process which is not contained in the standard output files or drawings. These are outlined in the next section.

Additional Design Output Data

Some additional data that might be needed in manufacturing could include mechanical models or 3D prints, as well as MCAD data for an enclosure. The data required depends on the level of service being requested from the manufacturer and the scope of work. For example, in assembly, some radial or axial lead capacitors may need to be bent over on their side in a very specific orientation; your 3D prints and a STEP file can show this clearly. Other documentation includes prints, multiboard assembly instructions, packaging instructions, and wiring harness/cable assembly documentation.

MCAD Outputs

Output files are most commonly built for assembly with a PCB vendor, but some EMS companies may provide an enclosure assembly or box build service. To aid in these tasks, MCAD outputs might be requested. In particular, this could involve a 2D dimensioned drawing in DXF format showing mounting/fixation features, or it could be a full 3D model (e.g., STEP or Parasolid format).

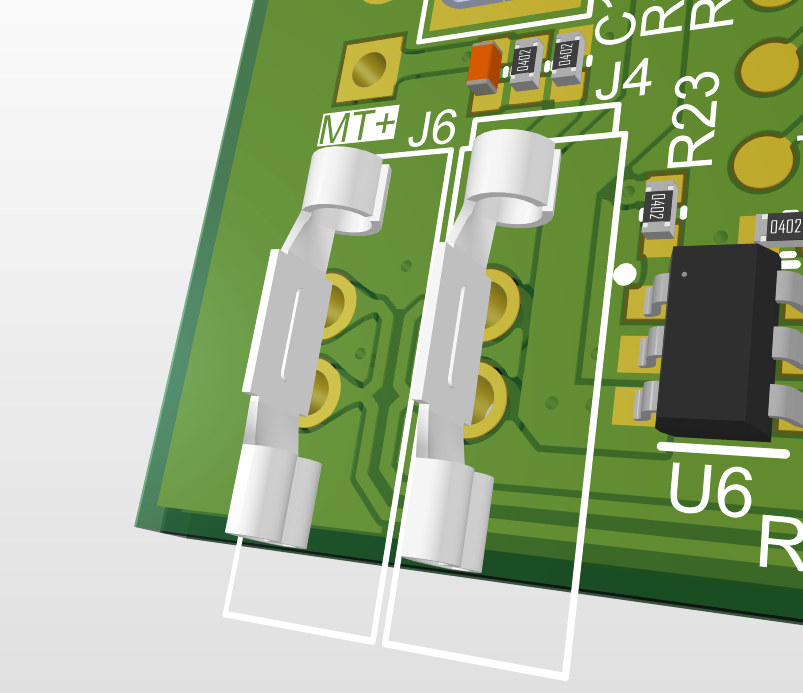

In some cases, viewing design data in a STEP file or as a 3D model in your PCB layout tool allows you to spot some DFM violations that may not be flagged by the online DRC engine. In the example is shown below, the connector outline on the silkscreen layer falls outside the board edge. When working in 2D mode in the layout editor, these defects types of can sometimes be missed, but they may be easier to spot in a 3D view.

Another specialized assembly requirement is with press-fit connectors or crimped connectors, which aren’t applied in a standard PCB soldering flow. Documentation on these components also needs to be provided; an assembly drawing or a specific requirements document might be the best place for this. If you’re unsure or you’re working with a new manufacturer, make sure to request this information and provide the right data accordingly.

Wiring Harnesses and Cabling

When your PCBA requires external connections through wiring harnesses or cable assemblies, additional documentation must be provided to the manufacturer. This typically includes cable assembly drawings that specify wire gauges, conductor counts, cable lengths, connector types and orientations, crimping specifications, and any required strain relief or protective sleeving. a wiring diagram or schematic showing the point-to-point connections between connectors will be required to ensure an assembler can build the wiring harness. These documents should also indicate any special requirements such as shielded cables, twisted pairs, color coding schemes, or labeling requirements.

Similar to PCB assembly drawings, wiring harness documentation should reference applicable quality standards (such as IPC/WHMA-A-620 for cable and wire harness assemblies) and include clear handling instructions, as well as testing instructions where applicable.

If the harness integrates directly with the PCBA through soldered wiring, press-fit terminals, or specific connector orientations, this interface information must be clearly communicated; this can be done with a callout in the main assembly drawing or the harness drawing. For products requiring both PCB assembly and cable assembly services, providing complete documentation upfront helps manufacturers understand the full scope of work and provide accurate quotes.

Additional Design and Layer Prints

Finally, layer prints can be generated which will show specific layes (or combinations of layers) in a single file. A great example is to show silk and mask layers in a single print, which gives a way to quickly inspect surface layer errors before PCB fabrication. These prints can be useful for providing a potential assmebler/fabricator information about your design without sending the actual design files or the manufacturing files.

It's also common for engineering services companies to work with clients who are not PCB design experts or who do not have CAM software to review PCB manufacturing files. Layer prints showing the mask, copper, or silk layers can help users clients review or understand the design without doing a live walkthrough in the PCB layout software.

What Happens if Something is Missing?

Anytime documentation is missing or an important fabrication/assembly requirement is not specifically stated, your manufacturer will likely email you requesting the additional information. In some cases, such as cheaper prototype manufacturers, the company will go with some “standard” capability and requirement that is applicable to most basic designs. If you aren’t worried about things like surface platings or tenting, then just focus on creating the main fabrication files and leave the rest up to your manufacturer. Different companies offer different levels of service and will be willing to help you get your first PCBA manufactured successfully.

Summary

In the past, designers had to prepare PCB design output files and manufacturing data by hand, which required compiling information from multiple design documents and manually preparing final deliverables. Today’s design tools can help you prepare this data package automatically so that you can save time and get through design reviews quickly. Next time you’re planning a new project, use the best CAD tools to help you quickly create a PCB layout and prepare it for production.

Once you’ve finished your PCB layout and you’ve completed a thorough design review, it’s easy to generate PCB design output files for your design in Altium Designer®. The OutJob file feature lets you create manufacturing file templates for your projects and quickly generate groups of files from your PCB layout and schematic data. When you’re ready to release these files to your manufacturer, the Altium 365™ platform makes it easy to collaborate and share your projects.

We have only scratched the surface of what’s possible with Altium Designer on Altium 365. Start your free trial of Altium Designer + Altium 365 today.

Back

Back