Design Verification Made Simple: How to Validate Your Component Choices Before Prototyping

The technology landscape is evolving fast, and so are product designs. As components become obsolete faster than ever, engineers face constant challenges to keep pace. Parts validation is a must for any new development, and the ability to validate at speed is what enables redesigns to move forward with little to no disruption.

For electronics designers, accelerating time-to-market depends on validating component choices early. They do this through a three-tier verification filter:

- Confirm specs via datasheets.

- Compare alternatives through parametric evaluation.

- Validate compliance and supplier reliability.

Leverage Comprehensive Datasheets and Documentation

Traditionally, component verification meant contacting a number of suppliers or sifting through multiple scattered, inconsistent data sources. Modern tools, like Octopart, simplify the process by offering engineers a single source for all the datasheets they need to make informed decisions quickly.

With Octopart, engineers gain instant access to detailed specifications, electrical characteristics, package information, and mechanical drawings, eliminating the need to trawl through countless distributor websites. Reliable, consistent data upfront makes it far easier to confirm that a chosen part truly aligns with a project’s design requirements.

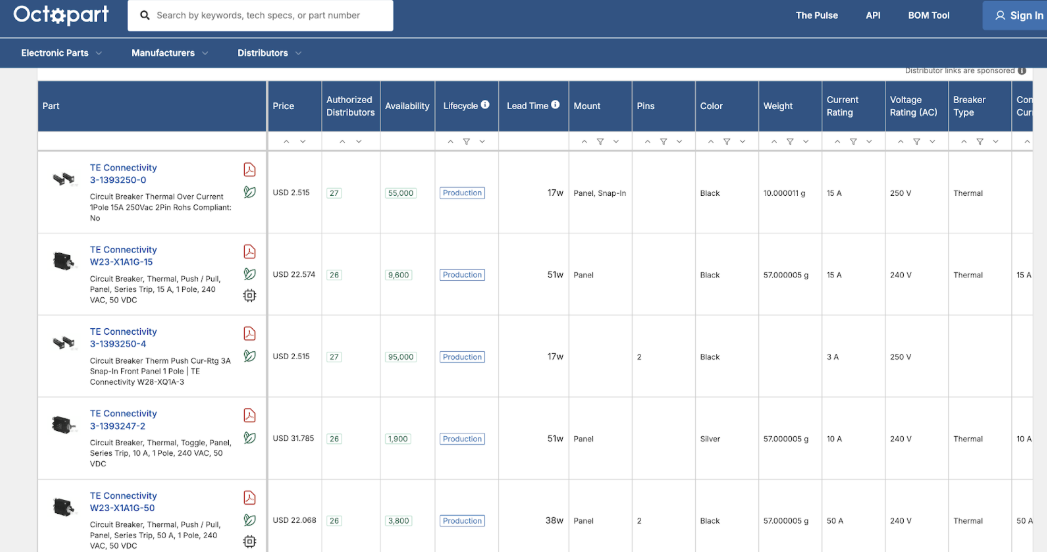

Use Parametric Comparison Tools

Selecting the most suitable part often requires evaluating multiple options and datasets to assess key factors:

- Form: Does the part match the physical size, shape, and footprint requirements?

- Fit: Will it integrate mechanically and electrically into the intended design without complications?

- Function: Can the component reliably deliver the required performance, and how might its characteristics influence thermal behavior or other specifications?

- Availability: Is inventory stable and sustainable over time?

- Price: Does the cost align with project constraints, and could subtle differences between components introduce hidden expenses later?

Octopart provides engineers with an extensive pool of parts and tools for parametric search and side-by-side comparison. Through this direct, data-driven approach, the chosen part is ensured to be the best possible fit, not just a close match. By removing uncertainty, engineers gain confidence that their design will perform as intended.

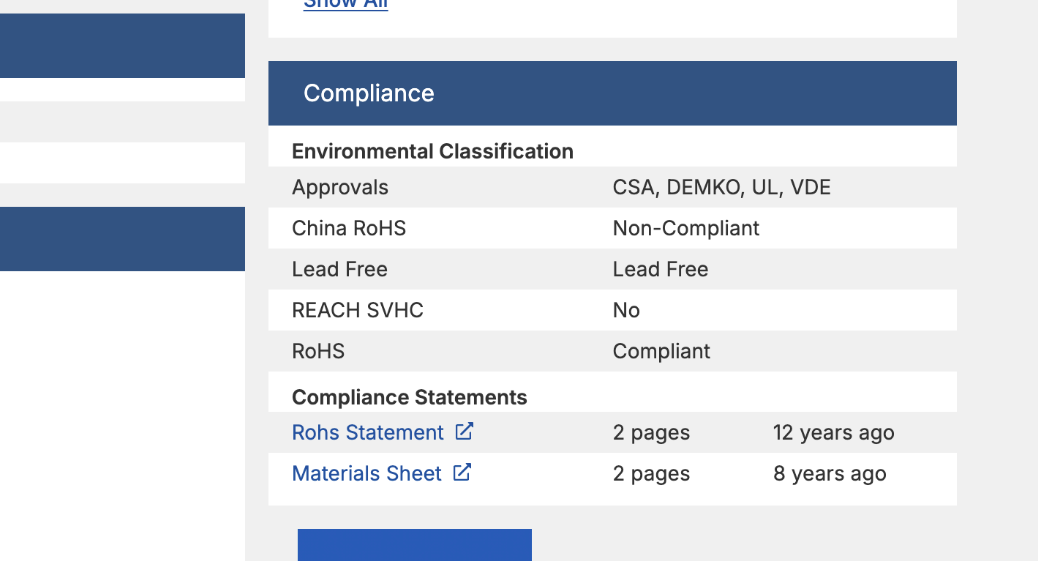

Verify Component Compliance and Supplier Integrity

For industries like automotive, aerospace, and medical devices, component compliance is a regulatory necessity, but also a critical factor in production continuity. Engineers using Octopart can confirm compliance with standards such as RoHS, REACH, and other certifications before locking in a component.

Alongside this, component counterfeiting remains a critical risk factor that can compromise product integrity, compliance, and long-term reliability. Mitigating this risk requires more than just availability data. It demands verified sourcing from trusted distributors, visibility into lifecycle status, and real-time market intelligence.

Octopart strengthens this defense by giving companies clear insight into where their components are coming from. The platform clearly distinguishes between authorized and non-authorized distributors, enabling users to prioritize traceable, manufacturer-backed sources while still offering visibility into alternative supply channels when necessary. By making supplier authorization status transparent, Octopart enables informed decision-making at every stage of the sourcing process.

Verify Smarter and Faster

Design verification doesn’t have to slow innovation down. It can be the very step that accelerates it. By bringing clarity to specifications, confidence to part comparisons, and trust to sourcing, Octopart helps engineers move from uncertainty to certainty at every stage of the design process. The payoff is faster prototyping, fewer disruptions, and the freedom to focus on building what’s next.

Back

Back