Case Study: How Companies Transformed Sourcing with the Octopart BOM Tool

Key Takeaways

- Unified workspaces accelerate quotes. When upload, matching, lifecycle checks, pricing, and purchasing live in one tool instead of being scattered across spreadsheets and distributor tabs, quote-to-buy cycles move faster with fewer surprises.

- Early visibility prevents redesigns. With the right tools, lifecycle and compliance risks surface before pricing work begins, flagging NRND/EOL status and RoHS/REACH concerns before layout locks choices in.

- Realistic pricing models mirror production buys. When teams model batch sizes, MOQs, and packaging formats in their BOM tool, pricing totals become credible, and purchasing decisions are made with confidence.

One Workspace, Different Stories

Across contract manufacturers, OEMs, and design services firms, we heard the same story. Teams were losing hours to spreadsheet gymnastics, tab-hopping between distributor sites, and discovering showstopper issues late in the quote cycle. Then, they consolidated their BOM workflow into the Octopart BOM Tool, and the friction dropped. With a single shared workspace, risk surfaced earlier, quotes moved faster, and confident decisions replaced guesswork.

The following case study draws from interviews held with engineering and procurement professionals who have adopted the Octopart BOM Tool. We've anonymized roles and quotes to protect confidentiality while preserving the substance of their experiences.

Who We Spoke With

We talked to people managing the quote-to-build process, including:

- A head of operations at a UK-based EMS provider handling quick-turn prototypes.

- A sourcing manager at a US medical device OEM who treats lifecycle vigilance as non-negotiable.

- A supply chain lead at a consumer IoT company who balanced alternates and continuity through pandemic-era shortages.

- A program manager at a design services firm who coordinates prototype-to-production handoffs where one misstep derails schedules.

Different roles, same challenge: get the BOM right, price it accurately, and order components without surprises.

The Problem: Spreadsheets, Stale Data, and Late Surprises

Before teams adopted a unified BOM workspace, the process commonly looked like this:

- Customer BOMs arrived incomplete or inconsistent, forcing manual cleanup before any real quoting could begin.

- Part numbers required manual mapping across distributor catalogs, making it easy to miss NRND or EOL flags until late in the cycle.

- Approved vendor lists lived in spreadsheets disconnected from market data, so policy drifted without anyone noticing.

- Packaging realities and minimum order quantities surfaced at the purchasing stage, often forcing rework and schedule slips.

One operations lead described the old routine: "I used to go through line by line, click on each supplier, go to their website, and add parts to the basket manually. It took forever." Compliance checks, lifecycle reviews, and pricing happened separately. Every handoff created friction, every check a delay. When everything is scattered across different systems, nothing moves fast.

What Changed: One Workspace, Clear Decisions

The Octopart BOM Tool brought the entire workflow into one place. Teams told us what changed at each step.

Upload and Match in Seconds

Teams can upload XLSX, CSV, or JSON files, and the BOM Tool immediately detects columns and aligns part numbers. Close-match suggestions repair partial or outdated MPNs, which prove especially useful for generic passives when customers omit exact part numbers. One project manager noted, "The BOM Tool makes it easy to compare parts side by side. I don't have to keep scrolling like I used to."

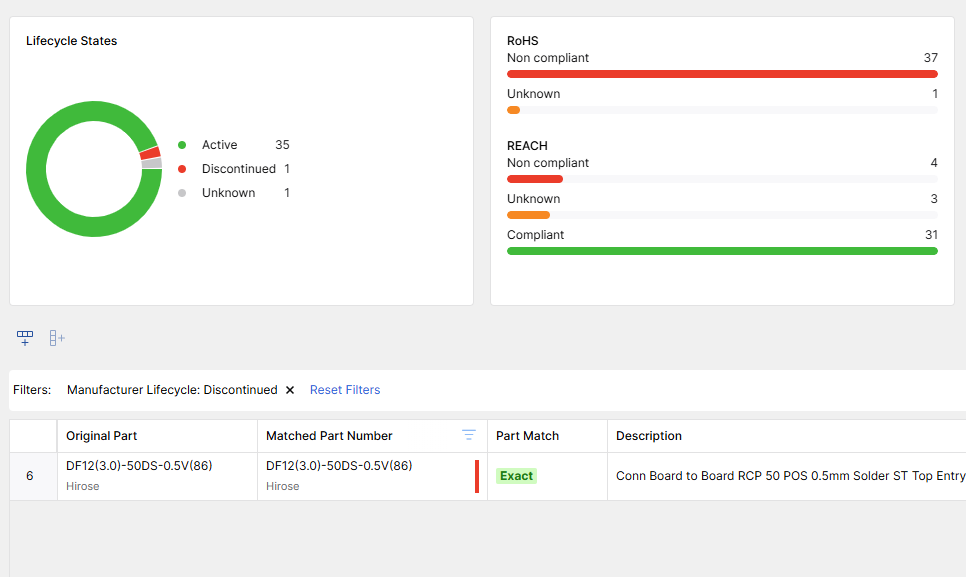

Lifecycle and Compliance First

The Octopart BOM Tool has a color-coded lifecycle status indicator (Active, NRND, EOL) and a dedicated Analytics tab that surfaces RoHS and REACH compliance risks before pricing begins. A senior design engineer told us, "CAD tools don't show lifecycle and availability. Octopart helps me avoid parts that will be dead in a year."

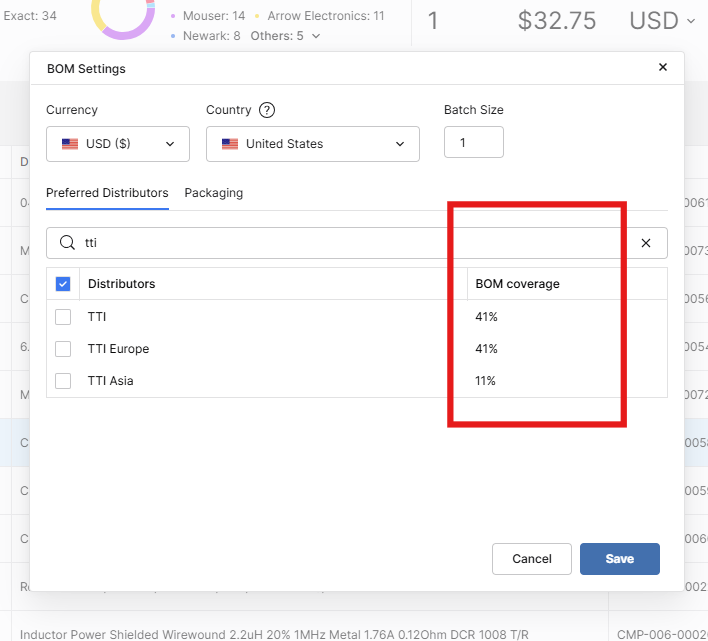

Policy Meets Market Reality

Preferred distributor settings keep teams inside AVLs while preserving visibility across the broader market. BOM coverage metrics show what percentage of the list each supplier can fulfill, making policy adherence measurable. As one operations lead put it, "There's such an extensive, up-to-date stock list across loads of suppliers, we've never felt the need to go elsewhere."

Model Real Costs, Make Smarter Decisions

Batch size adjustments, MOQ considerations, and packaging type selections (cut tape versus tape-and-reel) drive realistic extended totals. Teams see price breaks and inflection points before committing. One procurement lead shared, "I have Octopart open all day – checking stock, cost, alternative packaging, and datasheets."

One UK EMS team shared how a small BOM priced at $237 per unit dropped to $11 per unit when modeled for 100 units in the BOM Tool. Seeing those break points during quoting changes conversations with customers about batch commitments.

From Search to Cart

In-place alternate suggestions accelerate replacement searches. Hyperlinked exports preserve BOM structure for ERP workflows. Pre-built shopping carts on supported distributors eliminate manual re-entry. One user said simply, "When I see something out of stock, I immediately go to Octopart to find it elsewhere."

Results: Faster Quotes, Fewer Fires

Speed Without Sacrifice

When lifecycle and compliance issues surface at the start of the process, engineering and procurement spend less time revisiting decisions under deadline pressure. A UK EMS operations lead said, "Octopart has helped us grow as a business. Massively. We get quotes back to customers faster because everything is clean and organized instantly."

Risky Parts Never Reach Layout

Early flags on EOL and NRND components reduce design churn and schedule risk. One engineer summed it up: "Even engineers who say supply chain isn't their job use Octopart." When the data lives where designers work, better decisions happen naturally.

Policy Holds, Options Stay Open

Preferred-vendor filtering improves AVL compliance without eliminating market visibility. Teams identify coverage gaps and make informed decisions about when to expand sourcing or swap parts. The system supports governance without becoming a bottleneck.

Momentum Stays Intact

The Octopart BOM Tool facilitates side-by-side offer comparisons, fast alternate suggestions, and direct cart passthrough to keep work in a single flow. Context-switching drops and teams stay in sync. One lead called the BOM Tool "my massive source of truth."

Quantified Impact

Throughput That Scales

A three-person operations team at a UK EMS provider processes five to ten BOMs per day, with each BOM ranging from a handful of components to 150–300 lines for complex builds. Over roughly five years, the company doubled its headcount and tripled its revenue. Faster and more accurate quoting and cleaner sourcing contributed directly to that growth.

Always-On Usage

Procurement and engineering professionals keep the BOM Tool open throughout their shifts, checking up-to-date inventory levels, costs, alternates, and datasheets multiple times throughout the day.

Batch Economics Drive Strategy

Teams report that modeling batch sizes inside the BOM Tool has changed how they approach quoting. Instead of defaulting to prototype quantities, they now proactively show customers cost breaks at higher volumes, making it easier to discuss batch commitments during the quote phase.

Decision Clarity at Quote Time

Teams flag unavailable components early in the quote, giving customers time to re-issue lines or supply alternates. One operations lead explained, "If a part isn't available, we flag it on the quote so the customer can re-issue the line or supply an alternate. No scramble later."

Pro Implementation Tips

Based on our interviews, here are the practices that delivered the strongest results:

- Standardize before upload: Include MPN, Manufacturer, and Quantity columns for the strongest first-pass match and fastest cleanup.

- Use the Analytics tab first: Resolve lifecycle, RoHS, and REACH issues before optimizing offers. Fix weak lines early.

- Document policy exceptions in the BOM: If you intentionally broaden sourcing or approve alternates outside standard AVL, capture the rationale so purchasing can see it.

- Snapshot the quoting moment: Export a CSV at quote time to record what was in stock at what price, then re-check availability at buy time.

- Lean on description plus filters for generics: When customers don't specify MPNs for resistors and capacitors, use description search with package and value filters to speed up selection.

- Finish with exports or pre-built carts: Preserve ERP structure through hyperlinked exports, or push directly to supported distributors when ready to purchase.

For more hands-on details, see:

- Getting Started with the Octopart BOM Tool

- How to Simplify Component Sourcing with Octopart BOM Tool

Putting It All Together

When procurement and engineering use the Octopart BOM Tool to share one accurate BOM workspace, quoting accelerates, compliance friction drops, and purchasing decisions arrive with confidence. The BOM Tool supports that workflow from upload through risk checks and realistic pricing to completed purchase orders.