Manufacturing Cost Tradeoffs with FR4 PCBs

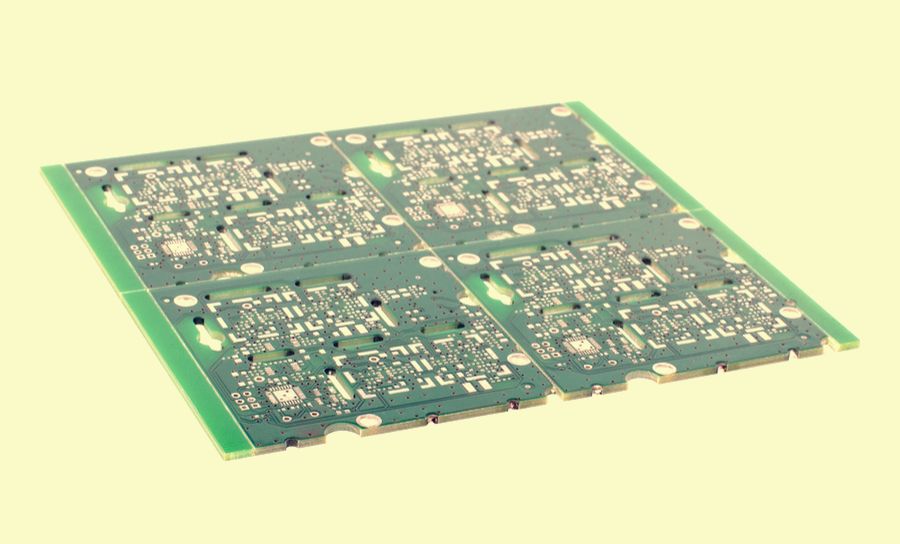

As the most commonly used material grade in the PCB industry, FR4 materials are plentiful, inexpensive, and well understood in terms of processing. Materials make their way to a huge range of products, and advanced FR4 versions are available for products with wireless capabilities or requiring higher reliability. Going even further, FR4-grade materials are also available for high-density designs with laser drill processing, further moving the applicability of FR4 into more diverse types of products.

Because so many designers will likely use FR4 in their designs, including designs produced at mass volume, it pays dividends to know the manufacturing cost trade-offs with FR4. This applies in terms of capability, processing, and electrical performance. Many of the cost differences in an FR4 PCB come down to two areas: base material cost and processing requirements. We will examine these factors in this article.

Base Material Cost

The base material cost is the first major cost driver affecting the cost of FR4 PCBs. There are many commercially available PCB materials classified as FR4 materials, and these materials vary in terms of their material properties. If you work with a PCB fabrication house and you start to build a quote with them based on their standard stackup, there will be two main factors that determine the base material price:

- Dielectric constant and dissipation factor

- Glass transition temperature

These are the two material factors used to delineate between materials used in PCB fabrication house standard stackups. We know this because these are the options that so many fabrication houses put on their quote forms. In some cases, you don't have a choice of dielectric constant; you will be limited to whatever the fabrication house provides in a standard stackup.

An exception is if you specify required materials based on their brand name or specific material properties. You can specify these for the fabrication house, but your fabrication house might need to procure those materials from a distributor or from the materials manufacturer. This results in one of the most common reasons for lead time extensions and unanticipated cost increases.

The major material impacting total board cost is the surface plating material. Low-cost immersion tin or HASL are easy to solder but are not designed for long-term reliability. Some designers will choose a more expensive ENIG or ENIPIG plating, which is suitable for long-term reliability. However, these platings are much more expensive as they contain gold, and there is no point in using them on prototypes. Some forethought about these materials during prototyping and production will help give a more accurate projection of per-board cost.

Layer Processing Costs

FR4 materials are compatible with standard photo image etching, as well as more advanced laser direct imaging for high-density circuits. As the traces and other copper features in an FR4 PCB get smaller, the trace size and spacing eventually cross a threshold where processing costs go up. While the FR4 base material cost is not impacted by etching alone, the situation changes when circuit densities become high enough for microvias to be used.

Vias are normally mechanically drilled, and the processing cost associated with building FR4 boards generally does not change based on the commercial FR4 product being used. However, when microvia diameters are small enough to require laser drilling, the FR4 material being used must be swapped for one that is compatible with laser drilling. Not all FR4 materials are compatible with this process. It requires modifications to the material chemistry in order to be laser-drillable, and these materials may carry an additional cost.

One mistake I see among new designers is the use of very small traces and vias when they are not necessary, with the size often reaching into the realm of laser drilling. To undo this mistake, significant rerouting of the PCB is often required, which adds further time and cost to the design. This is why it pays to know fabrication house capabilities and constraints early, before starting placement and routing of the PCB.

Lead Times Can Impact Your Budget

FR4 materials are produced under many brand names and are readily available, but some FR4 materials have come to dominate the market in certain parts of the world. In the US, two of the most common commercially available FR4 material sets are Shengyi and KingBoard. Both material sets are excellent options for many commercial products that only require standard processing and mechanical drilling. In particular, Shengyi is a common material used in fabricator standard stackups because it is so widely available. These materials also come in high-TG variants.

Both companies offer other FR4-grade materials which are more advanced, offering lower dielectric constant and lower loss tangent. Note that other companies manufacture comparable products which could be substituted for these common materials, but if you specify these alternatives, they may incur additional lead time as they need to be procured from a vendor. Lead times on these materials can vary from a few days to a few weeks, and this may be an unacceptable time delay in your project. This is despite the fact that certain materials may be specified as substitutes for each other based on IPC slash sheet.

IPC slash sheets are very useful tools for selecting compatible material sets and thus avoiding unexpected costs and project delays. For example, if your project specifies a less common FR4 material, and the fabrication house stocks a compatible alternate, you can avoid the additional costs and time required to procure the material in your specification. IPC slash sheet numbers give you the visibility required to quickly approve an alternate from the fabrication house material stocks.

Of course, there are valid reasons to specify a particular FR4 material and require that it be procured for your fabrication run. For example:

- A specific performance level classification (PLC) is required for high voltage

- A particular resin content is required, for example, to prevent CAF

- For vacuum or space applications, a low outgassing epoxy may be required

- Lower Dk/Df materials are required for high-speed PCB designs

Whether you need to build reliable power electronics or advanced digital systems, use the complete set of PCB design features and world-class CAD tools offered by Altium. Only Altium provides the world’s premier electronic product development platform, complete with the industry’s best PCB design tools and cross-disciplinary collaboration features for advanced design teams. Contact an expert at Altium today!