Reducing Costs with Efficient BOM Management

Are you looking to reduce material costs, minimize supply chain risks, and keep production running smoothly in the unpredictable supply chain environment? This article will guide you on how to achieve this in a simple way.

For every electronics manufacturer, the goal is to cut costs without compromising quality or production speed. A highly effective way to achieve significant cost savings in hardware design and procurement is through the efficient management of your BOM. A clean, well-organized BOM helps your team keep accurate, up-to-date information on every component, from resistors to microcontrollers. With clear visibility into availability, pricing, and alternatives, engineers and buyers can make smarter decisions early in the design process, long before small gaps turn into major sourcing challenges.

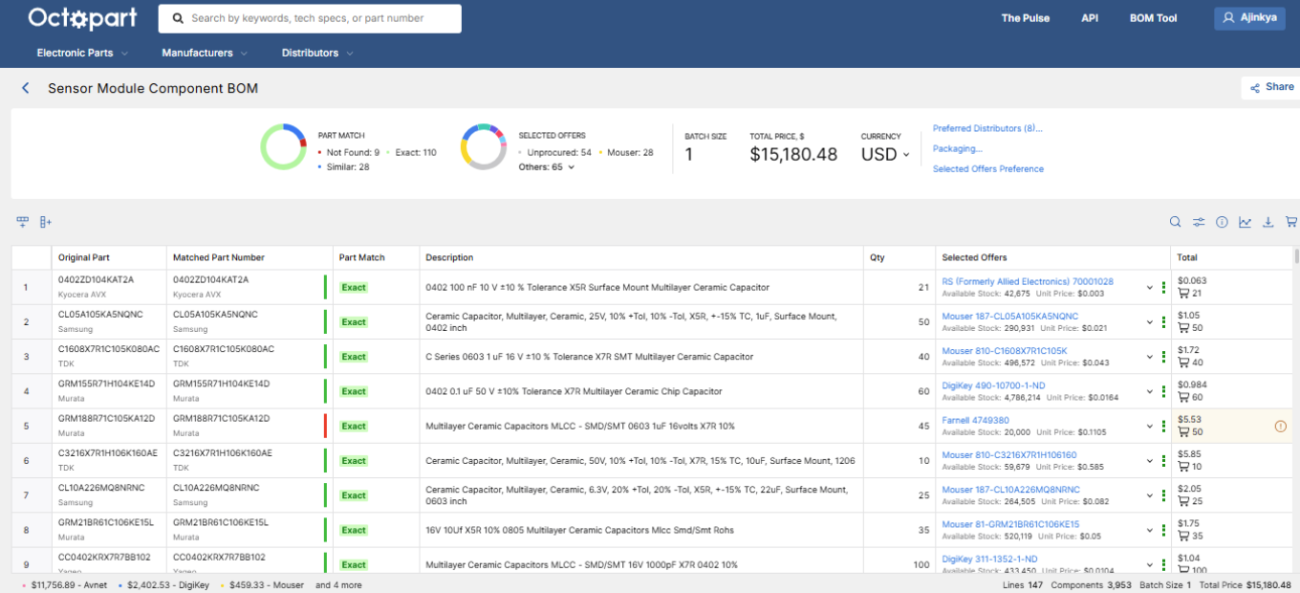

That’s where the Octopart BOM Tool comes in. It gives a clear and up-to-date view of your components, covering lifecycle status, availability, compliance, and alternative options all in one place.

Key Takeaways

- An up-to-date BOM is a core control point for hardware cost, risk, and schedule. Small errors or outdated data can snowball into re-spins, requalification delays, and major financial losses.

- Effective BOM management depends on clear visibility into lifecycle status, availability, pricing, compliance, and viable alternates so engineers and buyers can make tradeoffs early instead of firefighting later.

- Supply shocks like the Nexperia export ban highlight the need for proactive BOM risk management. Quickly finding and qualifying replacements is critical to keeping production and revenue on track.

Why Is BOM Management Important?

More than just a parts list, a Bill of Materials (BOM) is the blueprint for your product's design and manufacturing process. It details every component and serves as the foundation for procurement, assembly, quality assurance, and compliance.

According to the industry data, 80% of electronics designs require a part replacement, with each taking approximately 40 hours to source and validate. A single PCB re-spin can cost $46,000 in rework, and simple BOM errors like wrong quantities, missing components, or outdated supplier data can result in wasted $23,000 on a purchasing mistake or even a lost $500,000 contract due to delays in quoting or delivery.

Properly managing your BOM is exactly what prevents these outcomes. It protects your budget, reduces risk, and keeps your entire design-to-production workflow running smoothly.

BOM Cost Optimization Strategies

The table below shows how different cost-saving strategies work best when you have clear data, reliable alternate parts, and up-to-date pricing. Octopart gives you all of this in one place, allowing you to verify parts, compare suppliers, check availability, and find qualified substitutes so you can apply these strategies with confidence.

| PCB BOM Management Cost Optimization Strategies | |||

| Strategy | Potential Savings | Implementation Complexity | Risk Level |

| Volume Consolidation | 15-25% | Low | Low |

| Alternative Sourcing | 10-20% | Medium | Medium |

| Standardization Programs | 20-35% | High | Low |

| Supplier Negotiations | 5-15% | Medium | Low |

| Market Timing | 10-30% | High | High |

| Design Value Engineering | 25-50% | Very High | Medium |

Source: EMA Design Automation

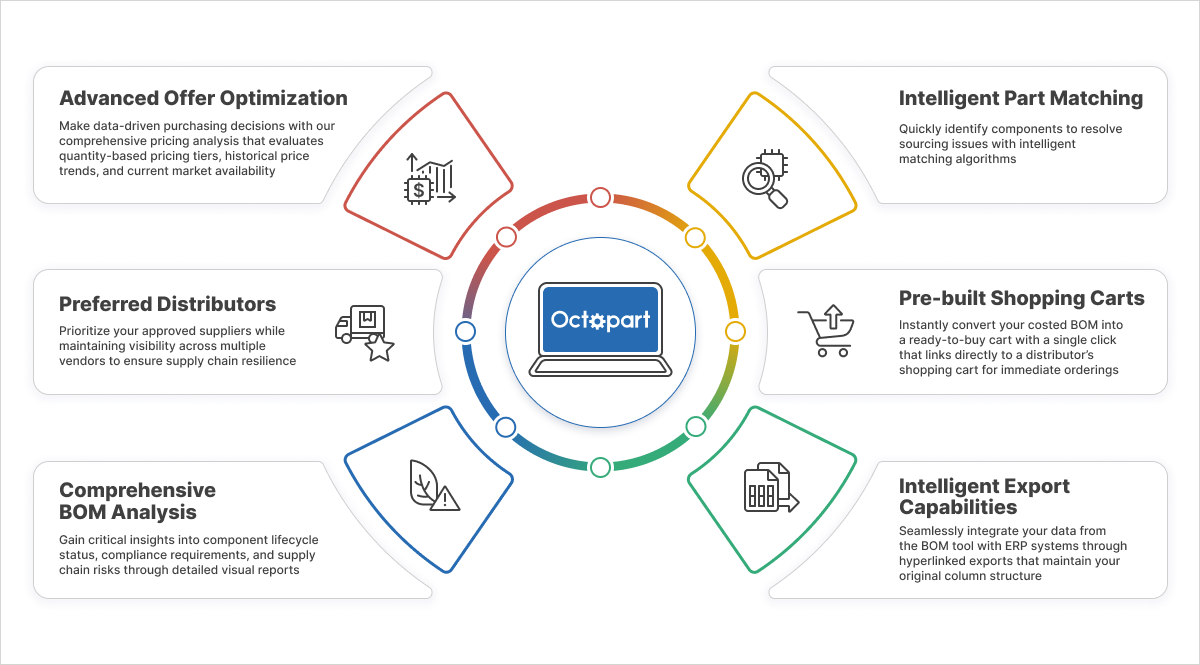

Octopart BOM Tool: Features That Save You Money

When you’re managing a BOM for an electronics project, every extra hour you spend hunting for parts, checking availability, dealing with obsolescence, or choosing cost-inefficient suppliers eats into your budget. Here’s how the Octopart BOM Tool helps you reduce costs and make quicker, smarter decisions.

- Clear, Up-To-Date Component Data: Instantly access over 95M components from 670+ distributors, along with up-to-date pricing and stock availability. With that level of visibility, you can avoid buying obsolete parts, prevent last-minute premium buys, and make truly informed decisions that actually fit your budget.

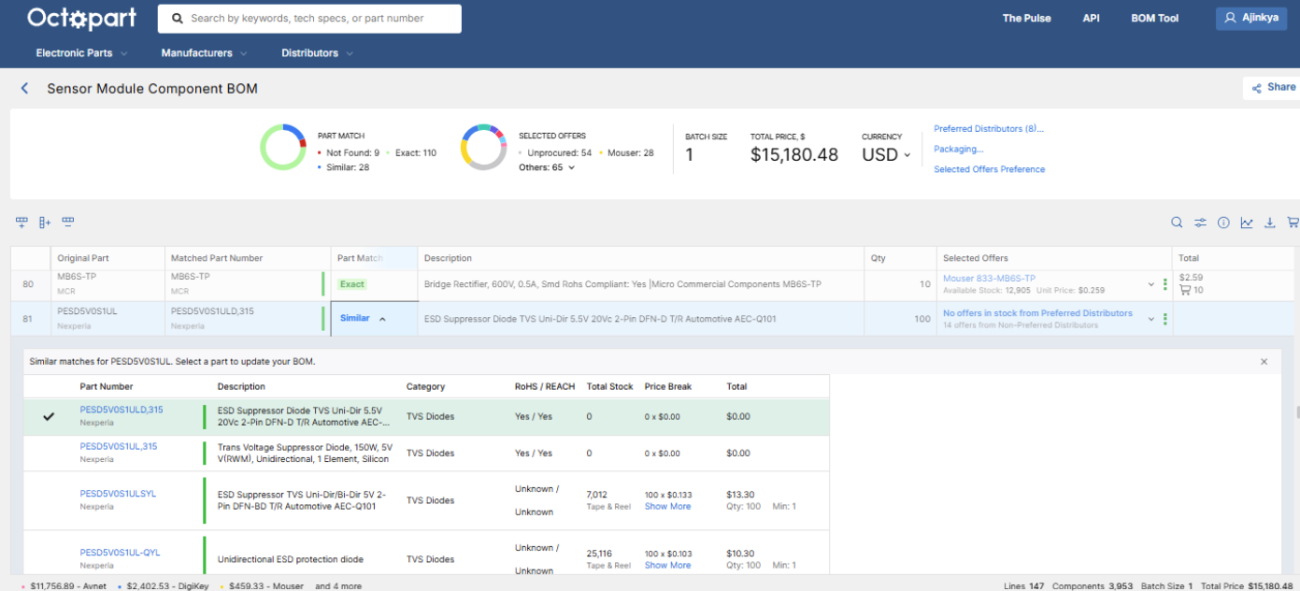

- Smart Matching and Alternate Suggestions: When you upload your BOM, the BOM Tool automatically matches part numbers and suggests cheaper or more available alternates to keep your design flexible and cost-effective.

- Price and Distributor Comparison: You can compare up-to-date offers, set preferred suppliers, and see bulk discounts instantly, making it easy to pick the best deal without manual searching.

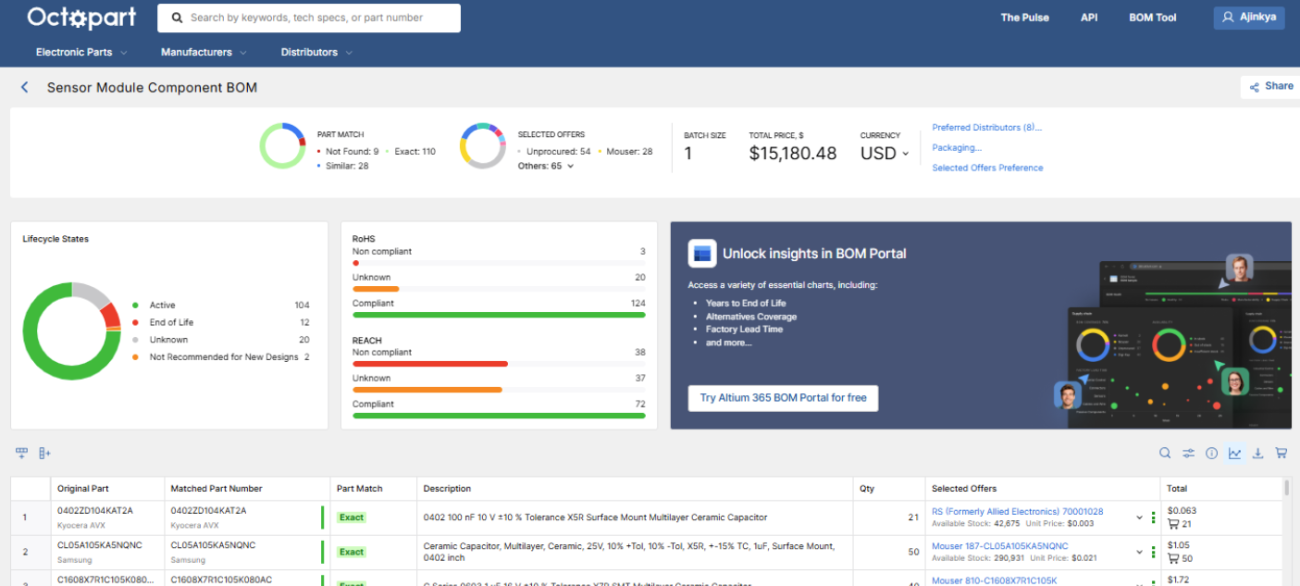

- Lifecycle and Compliance Insights: The BOM Tool highlights NRND and EOL status and shows RoHS and REACH compliance, helping you avoid risky or obsolete parts that could cause expensive redesigns later.

- Easy Export and Ordering with Octocart: Once optimized, you can export your BOM or send it directly to distributors’ carts, eliminating data errors and shortening the procurement cycle.

What the Nexperia Export Ban Taught Us About BOM Risk Management

One recent example of why BOM management is important is the Nexperia export ban. In October 2025, China’s Ministry of Commerce restricted Nexperia's Chinese operations and stopped the shipments of semiconductor components. The disruption had a large impact on the automotive industry, as Nexperia is a primary supplier of power chips used in electronic control units (ECUs) in vehicles. The companies had to requalify parts and adjust the production schedules to keep operations on track.

My procurement and engineering teams were initially in the same situation as many other companies facing the sudden impact of the Nexperia export ban. However, we mitigated this risk quickly by using the Octopart BOM Tool.

We uploaded our BOM and the tool instantly matched components, showing up-to-date pricing, availability, and technical data from a vast network of authorized distributors. As a result, we eliminated manual searching, reduced procurement hours, and avoided expensive last-minute orders.

The tool showed up-to-date inventory, pricing, and lifecycle status on every part using color-coded labels – green for active, orange for 'not recommended for new designs' (NRND), and red for end-of-life (EOL). It also checked for RoHS/REACH compliance to make sure every part we procure met the required standards.

With the help of verified alternate part suggestions, we quickly located replacements that met both electrical and form-fit requirements, avoiding costly redesigns and requalification delays, and reducing the need for premium expedited sourcing.

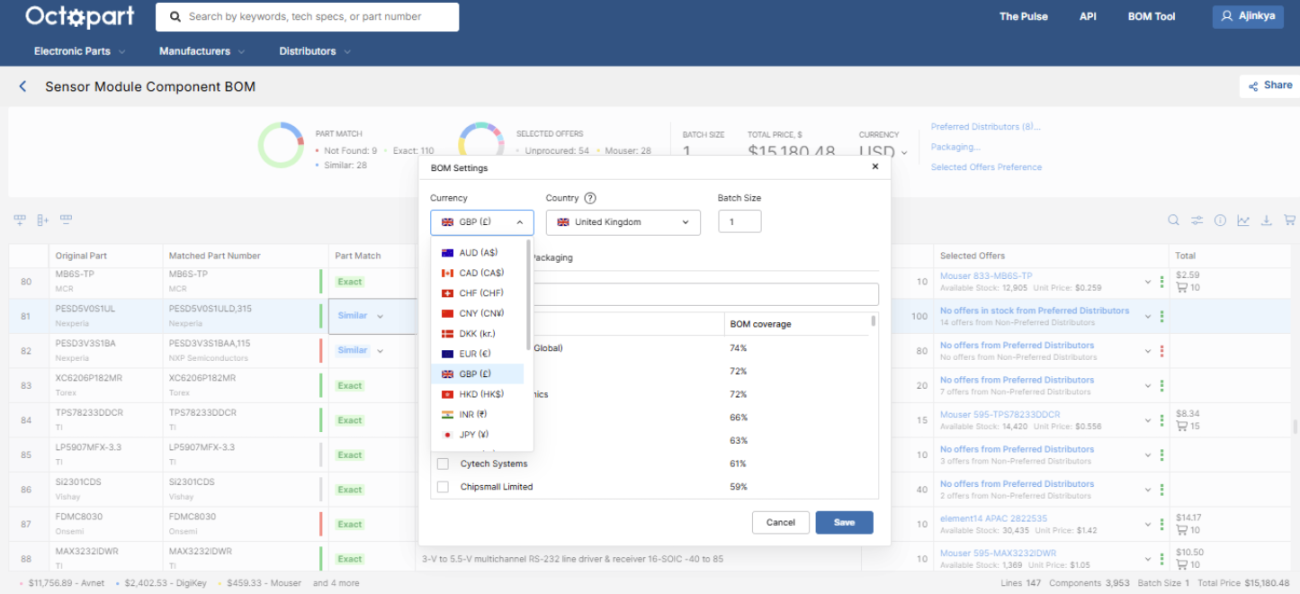

We filtered by preferred vendors, region, and currency to identify the most cost-effective and readily available stock for immediate purchase. That helped us keep our sourcing decisions in line with internal policies.

Once the BOM was updated, we exported a structured file that integrated smoothly with our ERP system, ensuring seamless coordination between procurement and engineering.

Why We Choose the Octopart BOM Tool for Cost-Efficient Sourcing

Efficient BOM management depends on a few essentials: broad market visibility, deep component data, reliable alternates, and up-to-date pricing. We use the Octopart BOM Tool because it brings all of that into one workflow, making it easier to control costs and make better decisions across the entire product lifecycle.

With more than 95 million electronic components, 1.3 million CAD models, and the data from around 670+ distributors, Octopart gives engineers and buyers a genuinely complete picture of the market. The platform processes over 208 million offers every day, 4 million searches per month, and more than 173,000 BOMs a year, so you’re always working with the latest, verified data. That level of depth, accuracy, and reach supports better pricing, better availability, and fewer surprises when it’s time to order.

Many platforms only list their own inventory, which hides alternative suppliers and often pushes teams to pay more for a part that’s available at a lower price from another supplier. Octopart pulls data from hundreds of distributors, so procurement teams can see the full market and choose the most cost-effective option that still meets the requirements.

Slow data refresh is another hidden cost driver, especially during disruptions. We used to rely on tools that updated their data infrequently, so engineers and buyers ended up comparing options based on stock levels and pricing that were already out of date. Octopart’s continuous processing of millions of offers provides a more accurate view of what can actually be bought right now.

Gaps like limited market visibility, shallow pricing intelligence, and stale data make it harder to react during supply shocks or evaluate realistic alternatives. With the Octopart BOM Tool, we can quickly identify suitable replacements, requalify components, and keep production running without delays or excessive premiums on impacted parts. Meanwhile competitors are still paying high premiums and struggling to develop a mitigation plan.

Final Thoughts

Octopart BOM Tool goes far beyond keeping your parts list organized. It brings sourcing intelligence directly into your workflow and brings engineering and procurement closer right from the start. The alignment reduces risk, shortens project timelines, and helps you avoid extra costs that come from late changes, stockouts, redesigns, and manual work. Start using Octopart BOM Tool today!