How Agile BOM Management Helps You Lock in Pricing Before Market Shifts

Supply chains can be unpredictable and locking in part prices is the deciding factor on whether you will achieve your margin goals or not. All it takes is a sudden increase in demand, a supply chain disruption, or a global event, and prices can suddenly go up or parts can disappear overnight. For complex product manufacturers, even a small delay or price increase can disrupt the entire production line, driving up costs and slowing delivery. This is exactly where agile BOM management software can turn risk into opportunity.

Important Takeaways

- Agile BOM management in Altium Develop allows up-to-date visibility into suppliers and market data for engineers and procurement managers, helping them lock in the best pricing.

- Automated procurement processes and updating the BOM reduce project delays and unexpected price increases due to sudden market changes.

- Integrated automation, such as obsolescence checking and alternate part recommendations, mitigates shortages, supply chain disruptions, and single-source risks.

- The latest BOM costing and supplier comparison allows you to make proactive decisions and lock in pricing to secure the best rate before the market fluctuates.

What Is Agile BOM Management?

Agile BOM management means managing BOMs in a flexible and connected way. Instead of keeping static spreadsheets that quickly go out of date, agile BOM management keeps all electronic part and design information in one live system that updates automatically. When someone changes a part, design, or supplier, everyone involved (engineers, buyers, and manufacturers) sees the update right away. This level of visibility gives companies a strategic advantage by allowing them to commit to component pricing before the market suddenly changes.

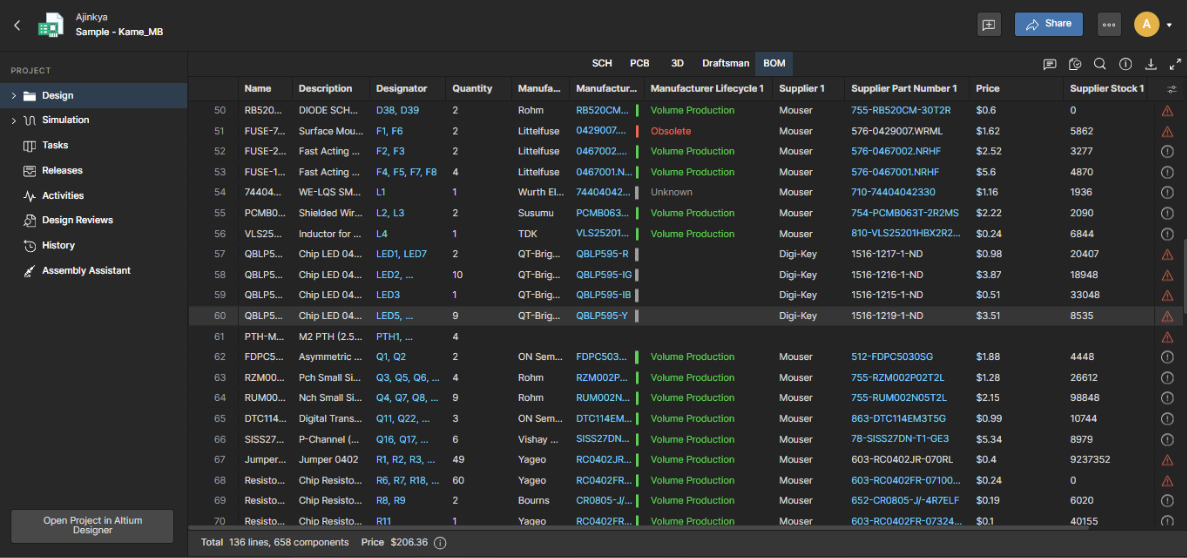

With tools like Altium Develop, design and procurement teams can access up-to-date supplier data, compare prices instantly, and analyze part lifecycles with ease. Far more than a simple part list, your BOM becomes an active hub helping you make smarter, risk-aware supply chain decisions.

Why Agile BOM Management Matters In an Unstable Market

The electronics component market is highly volatile, often disrupted by supply chain shortages, geopolitical tensions, and sudden shifts in demand. In such conditions, relying on outdated BOM data can have serious consequences, including missed chances to lock in lower prices, delays in sourcing critical components, and costly redesigns caused by end-of-life (EOL) parts.

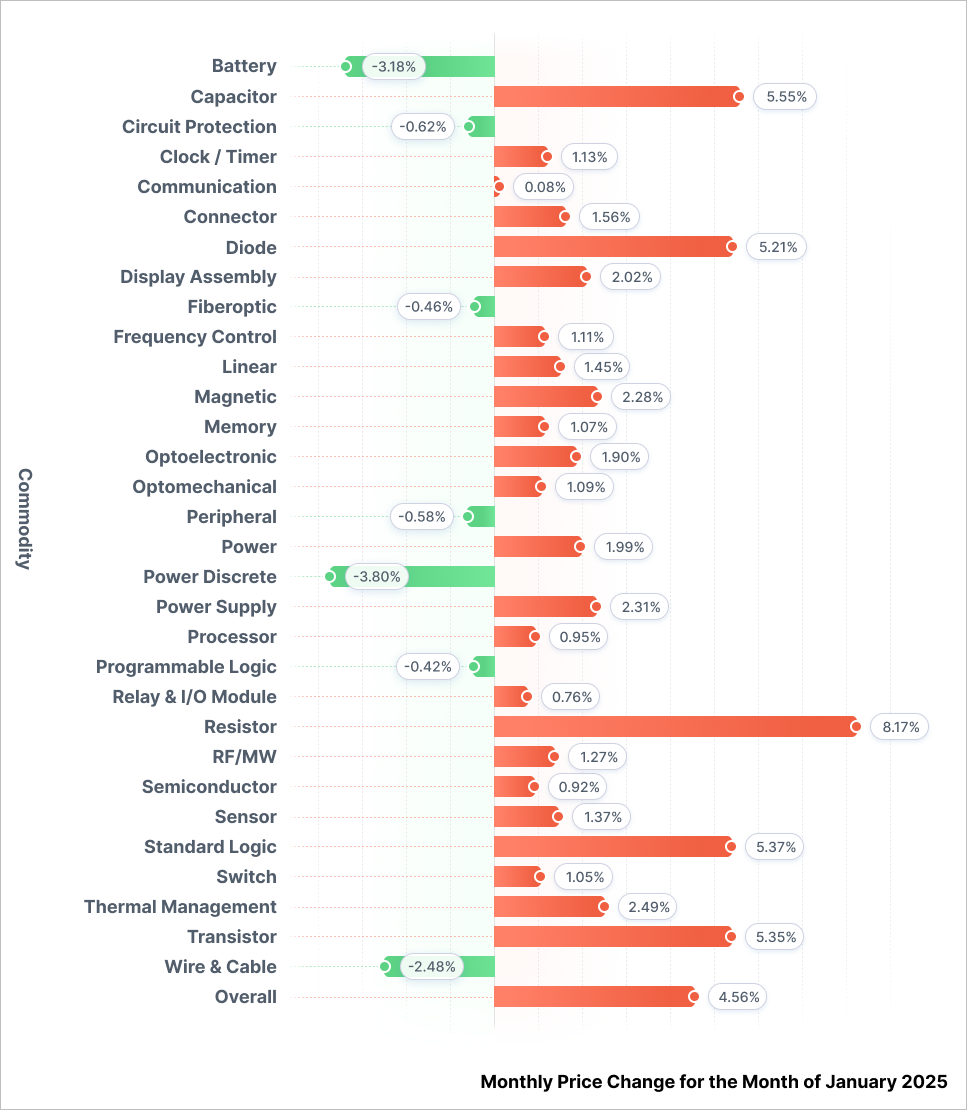

Lytica’s electronic component spend analysis shows an average component price increase of 4.56% at the start of 2025, the second-largest monthly increase in a year. This is driven by a significant cost increase in categories like resistors, capacitors, and standard logic, along with growing challenges over potential tariffs impacting global electronics procurement..

Agile BOM management helps companies stay ahead of these challenges by enabling up-to-date visibility, rapid response to market changes, and smarter sourcing decisions before disruptions escalate.

How Agile BOM Management Platforms Help Lock In Pricing

Modern BOM management solutions offer the latest access to pricing, availability, lifecycle status, and compliance information. Such visibility keeps you proactive to price changes, supply chain disruptions, and changes in the market. By incorporating up-to-date pricing, alternative part options, and price forecasts directly in your BOM workflow, design, and procurement teams can take action early to prevent price increases and component shortages.

1. Up-to-Date Pricing and Availability

The traditional BOM management tools often use static data, which make it challenging to respond quickly to real-time market fluctuations. Agile BOM solutions, like BOM management, are directly linked to supplier databases through integrations with sites like Octopart and IHS Markit. This connection means:

- You see the latest part prices across multiple suppliers.

- You’re notified about price changes or stock drops.

- You can act quickly before prices jump as a result of demand increases, raw material shortages, or geopolitical factors.

2. Immediate Supplier Comparison and Decision-Making

Agile BOM management platforms make it easy to compare suppliers side by side, factoring in price breaks, lead times, location, and availability. Such functionality enables design and procurement teams to:

- Secure the most cost-effective components in advance.

- Lock in pricing by placing orders early or signing supply agreements.

- Reduce the risk of being forced to buy expensive or last-minute alternatives.

3. Flexibility Enabled by Alternative Parts

Having alternative parts in your BOM gives you a key advantage when pricing or availability suddenly changes. Agile tools make this easy by allowing you to:

- Add multiple approved parts for a single component

- Pre-qualify alternate part numbers and suppliers

- Swap components in your BOM and schematic in one click

The built-in flexibility is a game-changer. If a primary part becomes out of stock or its price increases, you’re not scrambling. You’ve already lined up alternatives to keep your design on track and your budget under control.

4. Automated Alerts and Lifecycle Insights

Agile BOM platforms provide automated notifications for changes in the lifecycle, such as:

- End-of-life (EOL) notifications

- Last-time buy (LTB) opportunities

- Obsolescence risks

With such information at your fingertips, you can take action early, securing pricing and ordering parts before they go out of stock. This way you reduce redesigns and last-minute searches for alternatives and make for a smoother transition from design to production.

5. Cost Prediction with Confidence

Agile BOM tools don’t just show what’s in stock right now. They help you anticipate availability. You can:

- Forecast inventory risk using historical availability and lead-time trends

- Monitor supplier stock levels and detect patterns (seasonality, allocations)

- Set alert thresholds for low stock or sudden lead-time spikes

- Pre-approve alternates and buffer strategies for at-risk parts

This enables proactive planning and keeps procurement and engineering aligned to avoid shortages throughout the product lifecycle.

Expert Advice: Why Timing Matters

According to McKinsey research on supply chain shifts, companies using digital dashboards for end-to-end visibility were twice as likely to avoid disruption-driven issues. Organizations that adopted a more flexible and connected approach to managing their BOMs were better positioned overall. They secured parts earlier, negotiated better pricing, and stayed ahead of costly delays, while competitors still depending on static or spreadsheet-based BOMs lagged behind.

Platforms like Altium Develop play a big role here. By giving design and sourcing teams a greater understanding of the supply chain, businesses can negotiate more effectively with suppliers and secure pricing agreements sooner – before price increases or parts disappear from stock.

Keep in Front or Stay Behind

Component pricing and availability can shift in a heartbeat. But with agile BOM management, you are not just reacting to the market. You are getting in front of it.

Whether you are managing a tight timeline or trying not to be over budget, solutions like Altium Develop give you the visibility and control to lock in pricing, mitigate sourcing risk, and accelerate your decision-making without hesitation. Experience Altium Develop today!

FAQ

Can I automate component lifecycle and price tracking?

Yes, Altium Develop provides automated checks and notifications for both component lifecycle monitoring and price change, helping you to manage risk without manual tracking.

Can Altium Develop work with multi-currency pricing and global suppliers?

Yes, Altium Develop supports multi-currency pricing, and it is directly linked with a large network of global suppliers for the best price comparison and procurement across borders. This function is critical in today's international supply chains

How does agile BOM management improve collaboration between engineering and procurement?

Agile BOM management breaks down silos by bringing engineers and procurement teams together on a shared BOM platform where they can see up-to-date data, exchange feedback, and make informed decisions together. It also means they can respond faster to changes in pricing and supply risk, avoiding project delays.