Supply Chain Disruptions: Octopart Is Built for This

Geopolitics, extreme weather events, and the “innovation supply squeeze”—your supply chain holds countless points of failure. And when those risks aren’t addressed early on, the implications are predictable and painful: parts aren’t available when needed, or come at a cost you didn’t plan for, timelines slip, budgets are blown, and brand trust erodes.

When all it takes is a single poorly chosen component to derail a program, maturing your design process is the pragmatic solution that delivers business value. McKinsey report shows top design performers grow revenues and shareholder returns at nearly twice the rate of competitors.

In 2024, electronics and related sectors saw tens of thousands of discrete supply chain disruption events globally, with key categories like semiconductors, electronics, and industrials among the most frequently hit. Recent industry surveys also show that more than half of manufacturers still report significant supply chain disruption in 2024–2025, even as headline shortages have eased, underscoring that volatility is now structural rather than a temporary spike.

High-stakes, real-world applications demand reliable solutions that enable resilience from the start. Octopart’s tools make it easier to bake risk awareness into every component choice. By centralizing critical component data, including stock levels, lead times, and lifecycle status, Octopart transforms reactive problem-solving into proactive supply chain management, giving teams the structure they need to make early, risk-smart choices the norm, not the exception.

Here’s how.

Key Takeaways

- Supply chain volatility is a structural reality, with long lead times, frequent EOL events, and ongoing disruption across key categories like semiconductors and industrial electronics.

- Managing lifecycle status, lead times, historical inventory, and authorized vs. unauthorized distributors up front is critical to avoiding redesigns, schedule slips, and counterfeit risk.

- BOM- and part-level tools that centralize data (lifecycle, availability, specs, CAD models, risk flags) let teams filter out vulnerable parts early, evaluate alternates, and quantify risk at the design stage.

- Capabilities like intelligent part-matching, stock notifications, and BOM risk scans support a more resilient, proactive sourcing process instead of last-minute scrambling when parts disappear or lead times spike.

Lifecycle Status

Short IC lifetimes, commonly two to five years for advanced semiconductors, make early visibility essential.

Across the industry, roughly 750,000 components went EOL in 2022 and 470,000+ in 2023, with redesigns costing $20K–$2M, making early lifecycle filtering non-negotiable.

Octopart’s lifecycle status helps engineers filter out vulnerable parts from the start and design around components built to last.

Lead Time

Even in a “normalized” 2025 market, average factory lead times still hover around 34 weeks for passives, about 26 weeks for discretes and MCUs, and roughly 31 weeks for sensors, keeping many critical categories in the several‑month range. Outlooks from distributors also flag ongoing tightness in certain power, automotive, and AI‑related components, where individual SKUs can still approach 40–50‑week waits when demand surges.

Octopart gives engineers access to factory lead-time data for 95m+ electronic components, letting teams spot availability issues early and build designs around components that will actually be there when needed.

Part Specifications View

Octopart’s Part Specifications tab surfaces key attributes across millions of components, letting engineers compare specs and evaluate alternatives in one place. Industry analyses indicate that a large majority of PCB designs ultimately require at least one component substitution due to availability or cost changes, turning every spec decision into a potential re-spin if alternatives aren’t evaluated up front. By combining visibility with filtering power, teams can confidently swap risky or unavailable parts without derailing schedules.

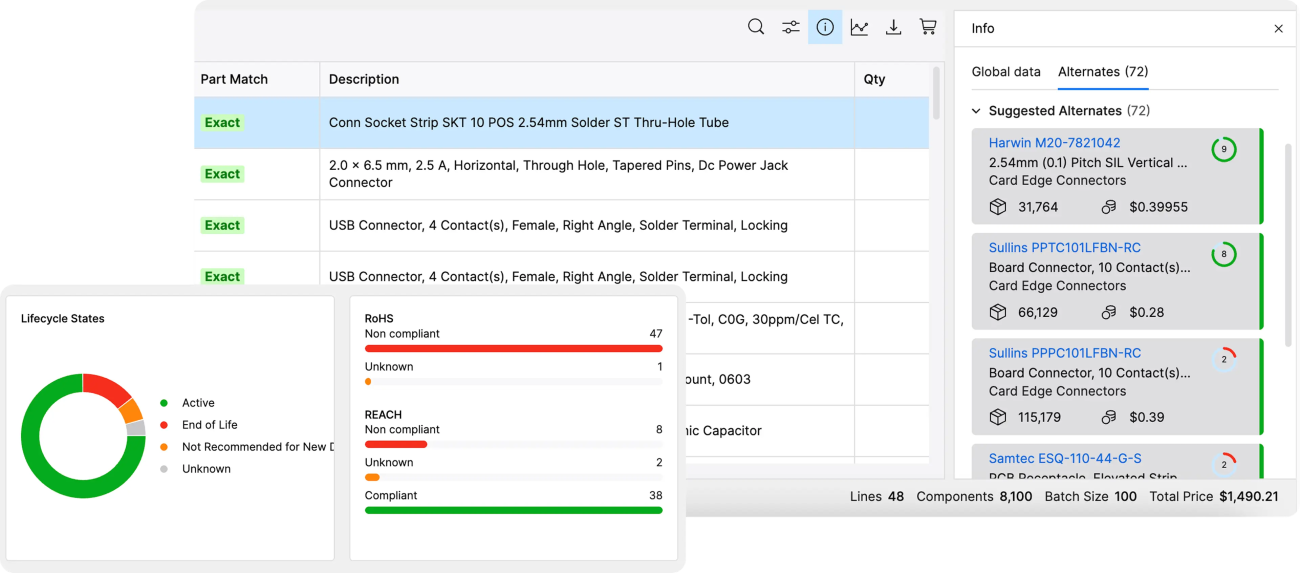

Octopart BOM Tool

The Octopart BOM Tool gives you an instant read on design risk. Upload a BOM and the tool flags parts that are unknown, discontinued, end-of-life (EOL), or not recommended for new designs (NRND), with clear availability indicators for every line. It’s a fast way to catch issues early—when roughly 80% of lifetime product risk and cost is locked in by decisions made during the product’s design phase.

When hundreds of thousands of parts go EOL each year, and a significant share without a PCN, an instant lifecycle and availability scan on the full BOM becomes a necessary early‑stage check, not a nice‑to‑have.

Stock Notifications

Octopart’s stock-notification feature lets you “watch” specific parts from chosen distributors and get an alert when inventory reaches your preset threshold. Since its launch, this functionality has helped teams track supply chain trends and respond quickly when stock levels change—whether they’re declining or reappearing. While it doesn’t eliminate global supply-chain challenges, it empowers you to act the moment parts become available or risk running low.

In markets where passives average 34 weeks and some SKUs hit 40–50 weeks, getting alerts and 12-month stock trends turn fleeting availability windows into secured supply.

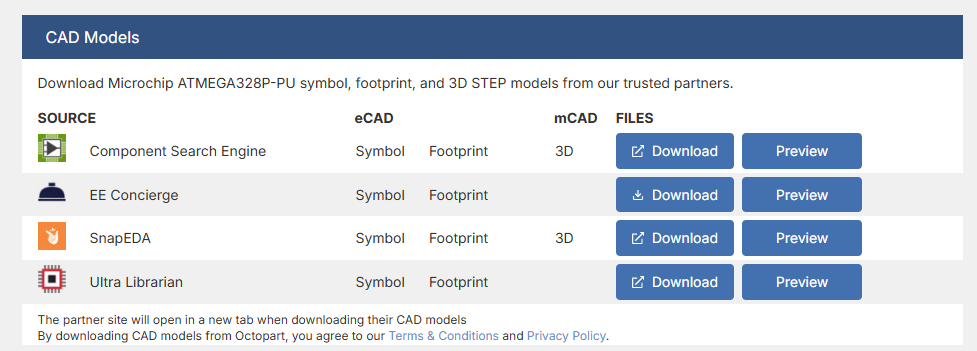

CAD Models

According to industry data, design errors, including footprint mistakes, account for up to 60% of PCB prototype failures, with major impacts on timelines and costs. Having access to millions of verified CAD models sharply reduces that class of error and the schedule slips that come with it.

CAD models in Octopart give you instant access to millions of verified, ready-to-use models that remove friction from early design. Accurate footprints and geometry reduce layout errors, cut rework, and eliminate the need to build models from scratch, keeping designs cleaner, teams faster, and late-stage surprises to a minimum.

Inventory History

Inventory History delivers up to a year of verified stock data, with 3-month and 12-month views that quickly show whether a part is steady or volatile. Backed by Nexar Spectra, it highlights restock cadence, stock-outs, and demand shifts that influence future availability. With this historical insight, sourcing teams can choose suppliers more confidently, forecast with greater accuracy, and avoid components that may undermine production plans.

Intelligent Part-Matching

When the parts you originally spec become unavailable or risky, the last thing you want is to scramble through dozens of datasheets, cross-reference footprints, and verify compatibility manually. Octopart’s intelligent part-matching system automates that process, offering alternative components that match critical parameters (electrical specs, pin-outs, package type, lifecycle status, and availability).

With intelligent part-matching, engineers and sourcing teams can:

- Immediately surface viable substitutes when a part goes out of stock or becomes obsolete.

- Compare alternatives in a unified view, with matching specs and up-to-date stock or lead-time data.

- Avoid “footprint traps” or subtle mismatches that cause redesigns or delays.

- Maintain design momentum, without compromising performance or compliance, even under supply strain.

In a world where component availability shifts rapidly, intelligent part-matching gives you agility: the ability to pivot fast with confidence when your original parts fall through.

Authorized Distributors

Octopart uses a simple star system to help you quickly assess sourcing risk.

- Green stars mark distributors authorized by the manufacturer or ECIA members, ensuring proper handling, warranties, and reduced counterfeit risk.

- Yellow stars indicate non-authorized stocking distributors — they hold inventory from secondary channels and can be helpful when authorized stock is unavailable, though extra caution is advised.

- Grey stars identify non-authorized dealers or brokers who source hard-to-find parts and appear only when no authorized or stocking distributors have immediate stock, requiring careful verification.

The labeling system helps teams make informed sourcing decisions and maintain supply-chain reliability.

Counterfeit and substandard parts remain a serious concern. Industry estimates suggest that counterfeit components account for a non‑trivial share of returns and failures in some electronics segments, with risk rising sharply when sourcing shifts away from authorized channels. Using green‑star authorized or ECIA‑member distributors wherever possible is one of the simplest levers to cut counterfeit exposure and avoid reliability issues that only become visible in the field.

Understanding the differences between these distributor types — their roles, risks, and when each makes sense — is critical to responsible sourcing and long-term product reliability. For deeper insight into how distributor status affects procurement choices, refer to Authorized Vs. Unauthorized Distributors in the Electronic Components Supply Chain.

Building Resilient Designs, Together

Octopart is built for supply chain disruptions because it helps you design and source with confidence, using the latest availability signals, lifecycle status, lead times, and stock history to spot risk early and keep builds moving.

With tools like intelligent part matching, you can quickly find viable alternates when shortages hit, reduce last-minute surprises, and make faster, better-informed decisions across the entire BOM.

Whether you’re navigating a disruption today or planning for the next one, Octopart helps teams stay resilient, responsive, and ready.

Let’s build a smarter, more reliable electronics supply ecosystem together.

Back

Back