Susy Webb On Self-guided Learning, Success and PCB Design Conferences

Judy Warner: Susy, tell us about where you work and what kind of PCBs you design?

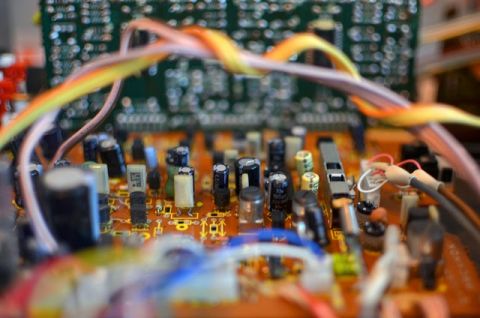

Susy Webb: I work for Fairfield Nodal in Houston, which makes oil exploration and monitoring equipment for land and ocean environments. The devices we make are spread out in an area and pick up energy waves that are sent down into the earth and return. Those energy waves can be interpreted and give an idea if there may be oil deposits in the earth in a given area.

Judy Warner: How long have you been designing boards, and what other types of products have you designed?

Webb: I’ve been designing PCBs for over 35 years. I have worked at service bureaus and companies that designed memory systems, computer motherboards, industrial computers, and now twice for oil exploration companies. I kept challenging myself and stepping up, and growing because I enjoyed the challenge and learning that goes with it. I believe anyone that is committed to always learning, and growing in this industry will make a great designer. You must be responsible for that learning, too. Don’t expect your boss or company to decide to send you to a conference or hand you a magazine article. I gained a great deal by going to conferences, and it gave me a base to build on. I went to all the classes I could afford. I have a degree, but not in Engineering--so I knew I could either self-educate by going to classes and conferences or go back to get an EE. Honestly, I wasn’t sure I would get the practical knowledge I needed from an EE program, so I looked at my conferences as an investment in self-education just the same as a tuition.

Warner: Why do you think people are resistant to travelling or perhaps spending their own money?

Webb: They may not have extra money to spare, or have the perspective that helps them realize how critical it is to their skill set or career trajectory. It’s to get in a particular company culture and just stick to that company’s methods and assume they’ve learned all they need to know. That’s ok if you plan to stay at that company, but what if they have a layoff or if you decide to move on. I believe designers have to be proactive about their career, and that includes buying books and standards and attending every learning opportunity they can.

Warner: So how did you end up becoming a designer?

Webb: Lots of classes, networking, books, and great mentors. I bought a lot of books and articles and highlighted them as I read. Authors like Bruce Archambault, Lee Ritchey, Todd Hubing, Henry Ott, Hall, Hall, and McCall, and Howard Johnson. I read some books several times because I wasn’t sure I fully understood them the first time. But you can’t just learn from books; you need mentors to help clarify things and answer real-world questions. I’ve been very fortunate to have people like Gary Ferrari and Rick Hartley as mentors through my involvement in conferences like PCB West and IPC’s APEX. When I would go to a conference, I could ask them specific questions about DFM or signal integrity for example. We could meet face-to-face and discuss these things in depth. I also volunteered my time, and am on the Executive Board for IPC Designers Council. I also joined committees which developed designer certifications and other standards. IPC is an international organization that people from around the world can join and contribute time as volunteers. I can’t emphasize enough the value of getting involved. I joined the IPC Designers Council executive board in 1998 and the Houston DC chapter before that. Unfortunately, Houston’s chapter is not currently active. We need some new people to step up and be a part of it. When the same officers have served for a long time, others need to step up and take a turn. I think people are reluctant perhaps they are afraid of getting pulled into doing too much—which I can understand. However, with just a few people sharing the work, it’s quite easy to run a chapter with minimum time investment.

Warner: What started you on this path of PCB Design, since you weren’t an engineering student?

Webb: I was an art major and had excellent manual dexterity! (You didn’t need to know much about electronics back then.) I started in the commercial art business but thought I might not want to go back to work full-time after having my first child and taking the brief six-week maternity leave which was standard at the time. However, I still wanted to make a little money. A friend of mine was a PCB designer that worked from home. She needed some help, so she offered to teach me to design boards. I learned from her and was employed by her for two years before I decided to start my own business and design bureau. I had a spare bedroom that could fit two giant light tables, and I worked 12 years from home. At that time all PCB design was done by hand, but the whole world was moving to computer-aided design (CAD). One of my customers offered to buy me a computer and software if I agreed to design their company's boards. That was in the late 80s, and the tool I used was P-CAD®. I worked long hours, often worked day and night to meet schedules and deadlines.

Warner: What do you believe are the greatest obstacles for designers today?

Webb: I think it can be hard to decipher what information is correct. There are many conflicting sources like datasheets, design standards, engineers, books, and articles and they may all say something slightly different. That is when I turn to a book or class from a source I trust, and of course, discuss it with the engineer. Often, the only way to know if the information works for your design is to analyze it all and apply what seems to be the most correct for your situation. Then test the board to verify the results.

Warner: What advice would you give to new engineers and PCB designers?

Webb: I would tell them to learn and study everything they can. Read books and attend all the classes you can and don't be afraid to ask questions during the class. (You will NOT be the only person who does not fully understand something!) Even electrical engineers are not trained in their college courses about how a signal will behave inside a printed board. Also, try to find one or several mentors. There are many designers out there that are getting closer to retirement, and they are eager to pass on their cumulative knowledge. The people leading the presentations at those classes will also be glad to help and can point you in some new directions sometimes. If possible, have instructors come to your company to talk to your whole department at the same time. I've been on the giving and receiving side of this equation, and it's great because it tends to get everyone on the same page! And of course, network!

Susy Webb, Sr. PCB Designer at Fairfield Nodal

There are online groups from IPC, software tools, manufacturers’ forums, and much more out there. Lots of help is available. It's also important to get involved in groups in your area or at a national level to be a part of deciding what information will get published out there. None of this is easy, but the benefits are invaluable, particularly in the jobs that a person would then qualify for and the salary they might earn as a reward for that hard work and knowledge. Every single job I have gotten in this business, I have found through networking!

Warner: So when you're not designing boards, what do you like to do for fun?

Webb: A lot of my time is spent developing presentations and classes. I enjoy it tremendously, and it helps me to learn more at the same time through my research. It has also taken me to some individual companies and conferences in the US and Canada, Mexico, and Australia.

I love to travel. I have a bucket list of people, places, and things I want to see, and I am working on that. I enjoy researching my genealogy and that somewhat ties in with my travels. Additionally, I like to read for pleasure, listen to live music, and of course visit with friends and family.

Warner: Susy, thank you very much for taking the time to share your history, insights, and advice with us.

Webb: My pleasure, Judy, always happy to share and help fellow designers!