Harness mmWave Routing with a Mode-Selective Transmission Line

High speed PCBs are pushing data rates into the stratosphere, putting tight design requirements on interconnects to ensure signal integrity and low losses. In an earlier article, I discussed substrate integrated waveguide routing for RF PCBs in an earlier article as one option for high frequency routing. This type of transmission line provides excellent isolation and is useful for simple transitions to antennas, but it’s not the only option for routing high frequency designs.

A mode-selective transmission line is one variation on a coplanar waveguide configuration for routing signals between components at very high frequencies. The goal in using a mode-selective transmission line or other geometry is to provide low dispersion and low loss routing in specific bandwidths with single-mode propagation. In this article, I’ll present this simple variation on coplanar waveguides and how you can use mode-selective transmission lines to provide high isolation routing with mode selection for RF applications.

High Speeds Bridge the Gap with RF Design

Whether you’re a digital designer or an RF designer, the push of high speed digital channels to higher frequencies is forcing everyone to take on RF concepts during design. John Coonrod, who happens to be one of my favorite speakers on this important topic, states very eloquently that concepts from RF design will be critical for digital signal integrity as we get ever closer to 1 ps rise times in practical applications. But what exactly is it that is causing us to hit the limits of standard trace geometries, and what can be done about this?

Remember, the standard PCB trace is a TEM transmission line, meaning the wave that propagates along the trace is approximately a plane wave. This holds at low frequencies until you start to reach mid-GHz bandwidths (well above WiFi frequencies!). When you get to high enough frequencies, you will start to notice behavior in the electromagnetic field that arises entirely due to wave propagation in the structure. This is where an alternative transmission line geometry could be useful to suppress higher-order (non-TEM) modes and ensure propagation to the receiver in the desired bandwidth.

Routing With Alternatives to TEM Transmission Lines

For the reasons I listed above, some waveguide geometries may be more ideal at very high frequencies and for very high data rate applications as they can be designed to allow single-mode routing, or rather they prevent excitation of non-TEM modes in a PCB waveguide. Some of these alternative routing geometries are:

- Substrate integrated waveguide. Take a look at this article to learn more about these structures. I’ve used these with a slot in the surface to couple to a conventional microwave waveguide flange.

- Coaxial stripline waveguide. This waveguide style has a stripline routed inside a substrate integrated waveguide, which involves 3 layers in total. The via wall in this waveguide provides isolation and allows diverse mode selection.

- Mode-selective transmission line. This is a variation on coplanar waveguide routing and provides many of the same advantages.

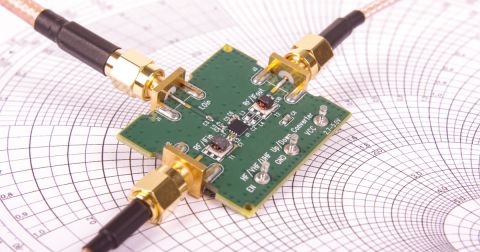

If you look in the research literature, these alternative routing styles have been around for a long time and have shown their feasibility for routing up to hundreds of GHz. These waveguide structures are simple to produce with standard fabrication techniques, but even they have limits once we get to extremely high frequencies. Among these, a mode-selective transmission line (MSTL) can be easily produced with a grounded coplanar waveguide geometry (GCPW) as shown below.

MSTL Behavior at High Frequencies (TE Modes)

The specific modes that get excited will depend on several factors, but primarily it depends on the interconnect geometry. In particular, as signal frequencies increase, the transverse modes in conventional microstrip or stripline traces will be excited, which is undesirable for both digital and RF routing. This is the reason we are running up against the signal integrity limits of conventional transmission lines, especially because we are so limited by the conventional PCB manufacturing process. For the designers who need to route at high GHz frequencies, you can engineer the GPCW structure to exhibit MSTL structure if you're designing an RF system, or you could engineer it to have maximum bandwidth for a digital signal if you're working with a high-speed digital system.

To see how this arises, take a look at the graphic below. Here we have some parameters we can use to control the mode frequencies in this structure. At low frequencies, the structure will act like a simple TEM waveguide because the propagating wave is below resonance. Above some higher frequency, the modes in the structure get excited, leading to peaks and valleys in the S-parameter spectra. Each higher order mode in the structure has a cutoff frequency, and simply exciting the structure above a cutoff will cause the electromagnetic field to propagate through the structure at a non-TEM mode. This possibility of higher order mode excitation is one of the fundamental limits on TEM transmission lines.

Source: Sain, Arghya, and Kathleen L. Melde. "Impact of ground via placement in grounded coplanar waveguide interconnects." IEEE Transactions on Components, Packaging and Manufacturing Technology 6, no. 1 (2015): 136-144.

If you look at the above reference and this article on digital signals in coplanar waveguides, you'll find corresponding S-parameter data that helps explain the power loss peaks shown above.

The reason all this occurs is wave propagation through the structure, which can excite the formation of modes on a standard interconnect. When the carrier frequency of a wave gets high enough, it could excite some modes in the transmission line structure in the PCB. This will create peaks and valleys in the insertion loss and return loss spectra. If you have a digital signal, these power loss peaks tell you that the signal could get distorted. For an analog signal, it limits the signal's frequency to specific ranges where excessive losses and distortion will not occur.

Isn't This Just a Grounded Coplanar Waveguide?

Yes! But what makes this style of waveguide important is the width compared to the wavelength of the carrier signal. The spacing between the vias is the most important mechanism you would use to control the useful bandwidth. This simple change in the width between vias isn’t the only difference between a grounded coplanar and mode-selective transmission line, but it is the major point used to predict the excitation of modes and the breakdown of the standard TEM transmission line.

Just to compare what happens during GCPW behavior and MSTL behavior, take a look at the following graphic. This graphic shows what happens when a signal's frequency gets very high and causes excitation of non-TEM modes. The TEM mode does not create excitation of a longitudinal magnetic field (Hz = 0 in the top row). At higher frequencies, we now have excitation of a TE mode, which will have a longitudinal field component.

Source: Fesharaki, Faezeh, Tarek Djerafi, Mohamed Chaker, and Ke Wu. "Guided-wave properties of mode-selective transmission line." IEEE Access 6 (2017): 5379-5392.

In a typical microstrip or stripline, you will eventually excite the parallel plate waveguide modes. Unfortunately, in these geometries, there is no way to suppress these modes except to make the laminate thinner, which will eventually reach its limit and isn’t applicable in all designs.

As shown above, waveguides have geometric parameters that can be tuned to allow or suppress various modes by selecting the appropriate geometry. The structure of a mode-selective transmission line gives it the following characteristics:

- High isolation. This is the primary benefit of routing in any waveguide, including a mode-selective transmission line. The grounded via fence along the edge provides shielding from other traces.

- Mode suppression. Modes in a mode-selective transmission line are a combination of a substrate integrated waveguide mode and quasi-TEM mode for the center conductor. The via fence spacing along the edge can be used to suppress substrate waveguide modes to ensure single-mode propagation.

- Broadband low dispersion. By suppressing a surface wave, you’ve ensured flat dispersion out to a higher bandwidth than in a microstrip or stripline. By keeping dispersion low over a broader bandwidth, there is less distortion and deviation from target impedance, which also suppresses intersymbol interference seen at a receiver.

Routing a Mode-selective Transmission Line in Your PCB

Routing a coplanar waveguide geometry like a mode-selective transmission line takes the right set of CAD tools. Here’s a simple procedure to route these lines:

- Calculate the wave impedance for the desired mode you’ll be working with. To do this, simply calculate the required propagation constant and use the standard wave impedance equation from an RF design textbook.

- Set the required clearance between your mode-selective transmission line nets and any nearby grounded polygons.

- Fill in the area around your routed nets with grounded copper.

- Place stitching vias on the selected polygon to hit your VL, VP, and SGW targets.

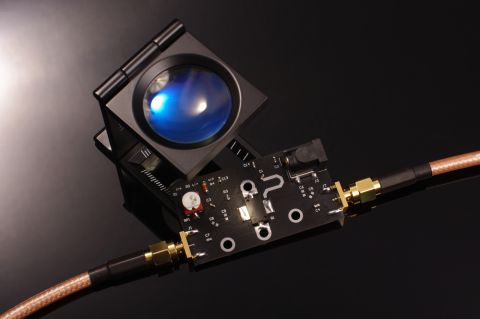

The example structure below is designed to provide 50 Ohms impedance out to 127.2 GHz. It is routed on 30 mil RO3003 to provide low-loss characteristics. It still has some DFM checking that is needed to ensure it can be fabricated, but the spacing, via sizes, and hole wall-to-hole wall separation are initially appropriate for the structure to provide low-loss low-distortion wave propagation.

This transmission line geometry has been shown to allow terabit per second data transmission and it may soon become a critical part of the high speed design landscape. In the above example for an RF line, if we wanted to exicte a specific mode in the structure, we could change VL and VP so that the 1st mode cutoff is at a lower frequency. To learn more about the theory of mode-selective transmission lines, read this paper from IEEE (cited above).

The interactive routing and layer stackup creation features in Altium Designer® give you the freedom to design any kind of interconnect you can imagine. The Layer Stack Manager provides highly accurate impedance calculations for standard trace geometries, or you can use the CAD tools in the PCB Editor to design your own non-standard geometries like mode-selective transmission lines. When you’re ready to release your board fabrication files and drawings to your manufacturer, the Altium 365™ platform makes it easy to collaborate and share your projects.

We have only scratched the surface of what’s possible with Altium Designer on Altium 365. Take a look at our flexible licensing options for Altium Designer + Altium 365 today.