Transforming RF Design with Ultra HDI

RF and microwave technologies are evolving at a rapid pace, and PCB design is changing right along with it. One of the most exciting innovations in the industry is Ultra High-Density Interconnect (Ultra HDI) technology. This advancement isn't just about packing more circuits into a smaller space, it's about improving performance, ensuring signal integrity, and tackling thermal challenges head-on.

If you're designing PCBs for RF applications, Ultra HDI technology is interesting. It's redefining how we approach high-frequency circuit design, allowing for sleeker, more efficient, and more powerful solutions. But what makes Ultra HDI so special?

Signal Integrity: The Heart of RF Performance

If there's one thing every RF designer knows, it's that signal integrity is everything. High-frequency signals are incredibly sensitive, and any interference or loss can mean the difference between a great design and a failed one. That's where Ultra HDI comes in.

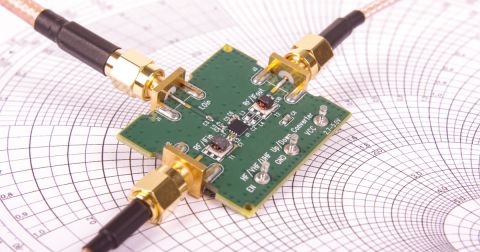

With controlled impedance routing, Ultra HDI features and tighter manufacturing tolerances on trace widths, ensures that signals move smoothly through the PCB, minimizing reflection and distortion. And llet'snot forget via placement—by strategically positioning vias, Ultra HDI helps maintain smooth impedance transitions, keeping your signals clean and consistent. Plus, low-loss materials mean signals can travel farther with less degradation. The result? A more reliable, high-performing RF system.

In RF designs, unwanted noise and interference can be disastrous. The advanced materials used in Ultra HDI help prevent signal degradation, maintaining performance across various environments. With increasing demands for high-frequency applications in telecommunications, aerospace, and defense, ensuring optimal signal transmission is more important than ever.

Boosting RF Performance with Ultra HDI

Performance is everything in RF design, and Ultra HDI delivers in ways traditional PCBs simply can't match. By reducing interconnect widths and lengths, it minimizes signal and insertion loss, meaning signals travel faster and more efficiently. This is especially crucial for broadband applications where high data rates and wide frequency ranges are necessary.

Ultra HDI is also built for high-frequency operation. Even at GHz frequencies, these PCBs maintain performance thanks to carefully engineered substrates and precision routing. What's more, the compact layouts allow for seamless integration of key RF components like amplifiers and filters. This not only saves space but also enhances overall efficiency. Whether you're working on a cutting-edge communication system or advanced radar technology, Ultra HDI helps bring your design to the next level.

Another major advantage is the ability to handle complex multi-layer designs without compromising performance. As RF applications become more sophisticated, the need for tightly packed components grows. Ultra HDI provides the necessary structure to support high-density layouts while maintaining stability and efficiency.

Managing Heat: A Smarter Approach

RF circuits generate heat—there's no way around it. But with Ultra HDI, managing that heat becomes much easier. One of the biggest advantages of this technology is its ability to incorporate thermal vias, which help dissipate heat efficiently and keep the system stable.

High-conductivity materials further enhance heat management, ensuring that even high-power applications stay within safe operating temperatures. Some designs even integrate cooling solutions directly into the PCB, such as embedded heat sinks or thermal pads. These features make Ultra HDI an excellent choice for applications where reliability under demanding conditions is non-negotiable.

Thermal management is particularly critical in RF designs used in aerospace and automotive applications, where excessive heat can cause significant reliability issues. Ultra HDI's ability to distribute heat effectively ensures that components operate within their optimal temperature range, reducing the risk of failure and improving longevity.

The Future of RF and Ultra HDI

Most designers don't know that Ultra HDI is responsible for ensuring our ability to operate RF devices up to very high frequencies. BGA packages with fine pin pitch and small via pitch coplanar waveguides are a hard requirement for routing RF signals around a PCB at mmWave frequencies, otherwise the signals will hit the limits of fundamental transmission line mode propagation.

With advanced mmWave sensor systems and data center products that will communicate with much higher data rates, Ultra HDI may be the only way to ensure signal propagation in a PCB. For RF designs, this could be enabled by the design of smaller via structures, which could push frequencies of operation beyond 100 GHz.

Final Thoughts

Ultra HDI is more than just an incremental improvement. It's a game-changer in RF PCB design. By ensuring superior signal integrity, boosting performance, and solving heat management challenges, it's paving the way for the next generation of high-frequency applications.

If you're working on RF designs, start thinking about how Ultra HDI can elevate your projects. The future of RF is here, and it's built on Ultra HDI technology. With ongoing advancements and increasing demand for high-performance PCBs, adopting this technology now will ensure that your designs remain competitive and future-proof.