How to Prepare Your Project for PCB Cart Manufacturing with Altium Designer

The electronics industry is massive and there are plenty of PCB manufacturers to choose from for your next order. When you need to prepare your next board for fabrication and assembly, how can you quickly generate deliverables for manufacturers like PCB Cart? Instead of generating all manufacturing documentation manually, designers need an easy way to create deliverables for fabrication and assembly.

If you plan to work with PCB Cart to produce your next PCB project, you need to use the deliverable generation tools in Altium Designer. The documentation features in Altium Designer take data directly from your schematics and PCB layout, and they instantly generate required manufacturing files in standard formats. Add in the supply chain and distributor integration features, and you’ll have everything you need to prepare your next PCB manufacturing order through PCB Cart or other manufacturers. Here’s why you should use Altium Designer’s complete suite of design and documentation tools to create your next PCB.

ALTIUM DESIGNER®

The industry’s only design application that helps you prepare for manufacturing through PCB Cart and other manufacturers.

Any new PCB comes with a range of components and particular design requirements, and a design team needs to properly communicate these to their manufacturers. Companies like PCB Cart are a great option for building out a quick prototype or large order during full scale production. Whether you want to work with a company like PCB Cart or another manufacturer, your team will need design and production resources to help you get your new order into production.

Altium Designers’ complete set of PCB layout, documentation, and supply chain tools are ideal for getting your new board into production through PCB Cart. This complete set of production tools is ideal for getting your new system built and produced with a single application; you won’t have to use external PCB supply chain services or CAD utilities to prepare documentation for your PCB Cart order. Here’s how Altium Designer helps PCB Cart customers quickly get into manufacturing with minimal delays.

Preparing a PCB Cart Order in Altium Designer

PCB Cart is a well-known manufacturer providing fabrication and assembly services to worldwide customers. Designers that need a quick-turn prototype or a full-scale manufacturing run can access these services through PCB Cart. Designers can also take advantage of turnkey manufacturing services, where PCB Cart will provide logistical support and supply chain management as part of a fabrication and assembly run. Some of PCB Cart’s capabilities include:

- Quick-turn prototyping with low layer count up to ~5000 pieces

- Full-scale manufacturing at any volume up to ~1 million+ pieces

- Quality and reliability inspection up to IPC Class 3

- HDI, rigid-flex, and heavy copper PCB fabrication

- Automated assembly services

Designers can produce a range of unique designs through PCB Cart and have them assemble with relatively low lead times. Whether a new design is intended for low or high volume production, PCB Cart customers need the best set of design tools to help them prepare their order for production and assembly.

Use Altium Designer’s Layout and Fabrication Tools for a PCB Cart Order

With Altium Designer’s complete set of schematic design, PCB layout, and documentation tools, a design team can move through the entire design process and prepare their new project for high-volume production. Altium Designer’s great advantage is the ability to do everything in a single application, including preparing all deliverables PCB Cart customers need to start production.

- Before you prepare your PCB Cart order, be sure to run through a comprehensive design review as this will help prevent manufacturing delays.

Learn more about running a PCB design review in Altium Designer before fabrication.

- When you need to put a new order into production with PCB Cart or another PCB manufacturer, you can use the best set of documentation features in Altium Designer to create the PCB manufacturing files your fabricator needs.

Learn more about the documentation your PCB manufacturer needs.

- Altium Designer has streamlined the entire design process to include schematic design, schematic capture, PCB layout, and manufacturing preparation in a single application.

Learn more about designing your circuit board in Altium Designer.

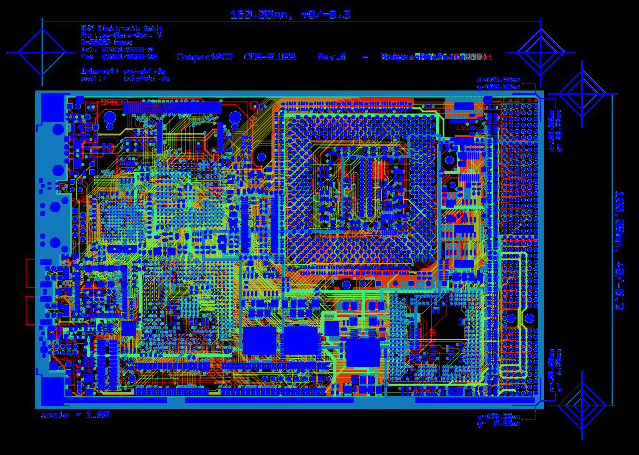

Altium Designer lets you instantly generate Gerber files and other documentation.

Sourcing Components For Your PCB Cart Order

Designers will need to create a complete set of PCB fabrication deliverables for their PCB Cart order, including the following sets of files:

- Gerber files

- Assembly and stackup drawings

- NC drill files in standard format

- Pick-and-place files for automated assembly

- Vendor-neutral layout data (ODB++/IPC-2158 files)

- A complete BOM with sourcing data

Even if you’re using PCB Cart’s turnkey service, you’ll need to ensure your components are sourceable as you create your design. Failure to identify obsolete or EOL components early in the design process can force a redesign once you send out your board for manufacturing. Instead of falling victim to component shortages, you can use Altium Designer’s complete set of supply chain management tools with supplier data integration to source components for your new design.

Access Component Sourcing Data Through Altium Designer

Altium has partnered with major electronics distributors and manufacturers to bring Altium Designer users a complete set of supply chain visibility tools and component sourcing data. These features are included with Altium Designer; users don’t need to use an external application to access PCB supply chain data and source their components. Altium Designer users also don’t need to browse distributor websites to find parts, and they don’t need to manually copy component sourcing data into a bill of materials for their PCB Cart order.

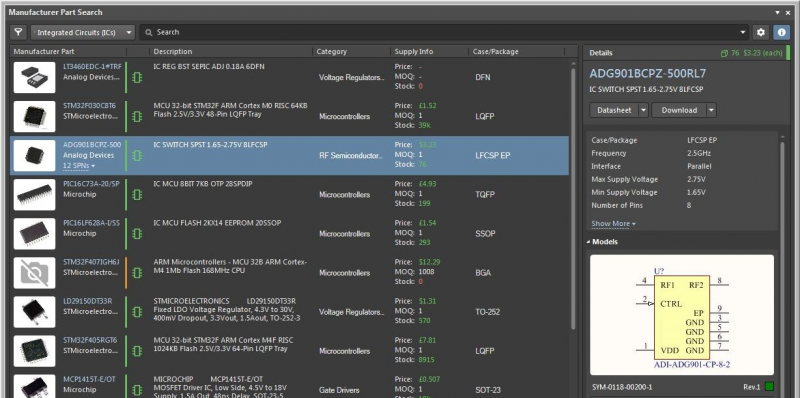

When you use Altium Designer, all sourcing data will be instantly imported into your BOM and all other design documents. This includes updated lead times, lifecycle status, costs, and available replacement components. All of this is available through the Manufacturer Part Search panel and the ActiveBOM utility in Altium Designer. With updated component data and sourcing information, designers have everything they need to stay productive and prevent redesigns before fabrication.

- Sourcing is an important part of the PCB design process. Design time can be reduced and redesigns can be eliminated when you can access sourcing data within your PCB design software.

Learn more about using sourcing tools as part of your PCB design strategy.

- Access to updated PCB supply chain data within your design tools helps you build a PCB manufacturing cost estimation and stay within your budget.

Learn more about creating a PCB manufacturing cost estimate for your PCB Cart order.

- Altium Designer includes the Manufacturer Part Search panel to help designers quickly find component data and footprints for their designs and to quickly build a BOM for their PCB Cart manufacturing order.

Learn more about the Manufacturer Part Search panel in Altium Designer.

The Manufacturer Part Search panel in Altium Designer.

Altium Unifies PCB Design and Supply Chain Management in the Cloud

Everything in the engineering design world is moving onto the cloud, but 3rd party data management tools can’t provide the design and management integration design teams need to be productive. Instead of keeping component libraries and PCB project data backed up on an external server or 3rd party cloud service, everything should be streamlined and accessible inside PCB design programs.

Altium has taken a major step to help PCB design teams stay productive and get through manufacturing quickly with a comprehensive design and supply chain management platform in the cloud. The new Altium 365 platform is ideal for remote design teams that need to track supply chain data, access design, and component data, and quickly send their designs out for production. Designers can manage all aspects of their project data and prepare their new designs for manufacturing through PCB Cart directly within Altium Designer.

Altium Designer Provides Complete Design and Manufacturing Integration

The power of Altium Designer’s integration between sourcing, design, and manufacturing comes from its underlying rules-driven design engine. The design features in Altium Designer use the same set of design rules and constraints throughout the design process. Designers can quickly create, evaluate, and release their designs in a single application. This ability to use a single rules-driven design engine for all aspects of a new project is key to eliminating redesigns and creating a new manufacturing order without delays.

- Altium Designer’s unified design environment gives users access to a complete set of design and manufacturing features in a single application. Everything needed to design, source, and manufacture a PCB is included in Altium Designer.

Learn more about the unified design environment in Altium Designer.

- Every Altium Designer user can access the Altium 365 platform and its sharing and data management features. This platform makes it easy to share and manage design and component data inside Altium Designer or on the web.

- When you need to bring component and design data management on-premises in a large organization, Altium Concord Pro provides an enterprise-level solution for data management.

Learn more about enhancing Altium Designer with Altium Concord Pro.

Altium Concord Pro on the Altium 365 platform provides supply chain visibility, component models, and data management features for any circuit board design project.

PCB Cart customers can have the most streamlined design and manufacturing experience when they use Altium Designer, the only PCB design platform that provides a complete set of design features for any new product. Whether you need to complete a small prototyping run or manufacture millions of units, Altium Designer has the design and manufacturing features PCB Cart customers need to be successful.

Altium Designer on Altium 365 delivers unprecedented integration to the electronics industry until now relegated to the world of software development, allowing designers to work from home and reach unprecedented levels of efficiency.

We have only scratched the surface of what is possible to do with Altium Designer on Altium 365. You can check the product page for a more in-depth feature description or one of the On-Demand Webinars.