PCB Design Guide for Engineers: Part 1 The Team

Who is involved in the PCB design and engineering process? Creating a PCB layout is a team effort, not just one person’s responsibility. Multiple engineering and scientific disciplines come together to make your vision a reality. As the project engineer, your first step is identifying and assembling your PCB design team, ensuring all key roles are covered for a successful project.

PCB Design Guide for Engineers Part 1: The Team

This PCB Design Guide for Engineers: Part 1 is the first in a free PCB design books series serving as a handbook for the novice/student, or electronics engineering professional. The series will give you an understanding of the methods, stages, and practices in producing a printed circuit board (PCB) from an engineer’s vision. From conception to delivery of the fully assembled PCB, we guide you through basic design stages using online PCB Design Software along with proven industry practices that can be tailored to your particular needs.

Understanding the Key Players in PCB design team

The members of your staff can be the following (See Figure 1):

Figure 1: Basic PCB design team organization.

Design Engineer

You — Yes, you are in the driver’s seat as a PCB engineer, balancing both performing your tasks and managing the PCB design teams listed below to bring this PCB to life. And, you are responsible for the end PCB board product. The final sign-off and approval are yours. The buck stops here.

The success of your product design cycle rests on your ability to manage your internal and external resources effectively along with the many free PCB engineers' software tools you may use to complete your product development

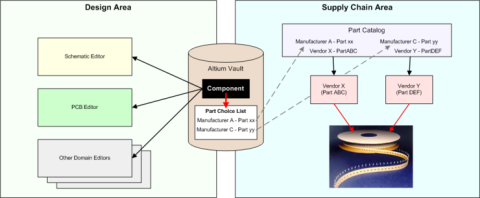

ERP/MRP System

Enterprise resource planning (ERP) and material requirements and planning (MRP) are where it all begins. From the initial concept to the final product, your ERP/MRP system plays a significant role in the design and development of your processes and planning. Most of the software tools used by your team for the design and development of your products interface directly with your MRP PCB materials system. Altium Designer Book has a supplier link system that can link directly to your ERP/MRP system using an open database connectivity (ODBC) connection. Having this link available to external supply resources along with a link to your company’s parts database allows you to seamlessly integrate all of that data into your supply chain.

PCB Designer CID+

This team member should be well-versed in all facets of the design and PCB layout process. In fact, in some cases, you may just have to hand over the completed schematic and bill of materials, and the PCB designer does the rest, including managing the entire process for you. This allows you to have the freedom to focus on other project-related tasks. The PCB designer has an understanding of the electrical characteristics of electronic circuits and how to apply and produce the documentation required to fabricate and assemble a PCB. In addition, the designer should be well-versed in the material sciences related to PCB manufacture, as well as the processes related to PCB assembly.

It would be well suited to have a designer who has been trained and holds the title of CID (Certified Interconnect Designer- Basic) or CID+ (Advanced) from the IPC — Association Connecting Electronics Industries. CID and CID+ are valuable professional credentials recognized throughout the electronics industry. Altium Designer® in the hands of a skilled PCB designer delivers the PCB design tools to get the results you are looking for in a finished PCB design book.

(Note: If you are not using a PCB Designer, then you must defer to your mechanical engineer who would be able to design a PCB and traverse the landscape of the external fabrication and assembly resources as well as be an invaluable resource when it comes to the documentation process.)

PCB Designer 2 / Librarian

You may have an organization with more than one PCB designer. The second PCB designer may or may not have CID certification. Know the strengths and weaknesses of your PCB design teams and assign tasks accordingly. A junior PCB Designer may be assigned the task of managing your company library or you may have a dedicated librarian in place.

Your library contains complete data on the components that will be used in your design, as well as schematic symbols, PCB footprints, 3D models, and any related documentation to rigid-flex PCB design. It is a fundamental element in determining the success or failure of your designs. Guidelines must be created to govern the creation, management, and storage of the library.

PCB Service Bureau

Your organization may not have enough resources to complete a project with many PCBs. You may require the services of a PCB service bureau to help with the completion of a large project. A PCB service bureau usually consists of a group of highly- skilled PCB designers with many years of experience in the industry. The services they provide vary from service bureau to service bureau. Some may provide only design services while others may provide complete turnkey services where they are responsible for the delivery of the completed PCB prototype and assembled printed circuit board.

Choose wisely as to which designs you want to send to an outside resource. Even though you are outsourcing the actual design, someone must be tasked to manage that outside resource to ensure delivery of a design package and finished assembly that does not require rework by your internal resources and impacts your design timeline. The file export and file packaging capabilities in the Altium Designer book are well-suited for providing your external design resources with a complete set of the information they need.

Mechanical Engineer

Your mechanical PCB engineers are involved early on in the design process, helping to develop models of the initial concept of the enclosure that houses the PCB. This person works closely with the PCB designer to ensure the marriage of the PCB to the housing meets the requirements of the design intent. The design process can be unforgiving in this respect in that changes to the form, fit, and function of the PCB can often come throughout the design process, and sharing the data between the PCB designer and mechanical engineer must be seamless. Altium delivers in providing multiple output formats for interfacing with mechanical engineering toolsets as well as providing the Draftsman tool that can be used by a mechanical engineer to facilitate documentation.

Purchasing

Your resource to your external resource is the purchasing department. Purchasing manages (and pays) fabrication, assembly, turn-key, electronic component distributors, testing facilities, and testing equipment. Your purchasing department should be able to provide you with information and access to a wide variety of external resources that allow you to meet your short and long-term goals. An Altium Designer Viewer license can be valuable for your purchasing department to access bills of materials and other output data formats they may need access to communicate vital information to your outside resources.

In-House Assembly

This department should have highly skilled personnel who can deliver an assembled PCB. Utilize them for prototype assembly. They can sort out issues with placement in the early stages of the design process. Collaboration with them is essential throughout placement and in identifying issues with proper documentation that does not impede the design schedule. An Altium Designer Viewer license can be used by in-house assembly management, affording them access to documentation and allowing them to be better prepared for commencing assembly.

Quality Assurance

Your quality department can work hand-in-hand with your external fabrication and assembly resources to ensure the delivery of a finished assembly that meets the product specifications. A properly outfitted QA department has the resources available to them to inspect incoming assembled PCBs properly. IPC mentioned earlier, can provide organizations with all the documentation, training, and certification needed to perform these tasks. They also maintain a set of standards, which facilitate interfacing with fabrication and assembly.

PCB Fabrication House / PCB Assembly House

Choose wisely. With the support of your purchasing department, you should have many options in the choices you can make. Pricing, lead time, and availability of components and materials are just a few of the factors that can affect the delivery of a bare circuit board or even a completed assembly. Some vendors specialize in different areas such as quick turn prototypes high quantity orders with long lead times, or a variety of combinations of services that fall under the Turn-Key umbrella. Altium Designer book benefits your PCB design teams with the existing ability to export a broad range of PCB design book fabrication and assembly file formats. Vary your choices and develop relationships with fab and assembly houses so that expectations from both sides are met.

Advanced Testing

If you need advanced testing for a circuit board, remember that depending upon the test or tests required, it adds a significant amount of time to the end of the design cycle. Having a design environment like Altium Designer can afford you the ability to provide real documentation early in the design cycle, to quote early on, and be able to forward any changes that may affect the final delivery of tested PCBs.

Building a Strong PCB Layout Team for Success

Orchestrating all of the activities and tasks for product design can be a daunting effort, to say the least. As we continue the series through this guide, we will introduce you to proven design methodologies and design review procedures that increase success in delivering the desired finished design.

Team members' understanding of their roles in the multilayer PCB design & engineering process is tantamount to the measured success of the project. Team members must also have the proper tools to complete their tasks. While internal team members may have the tools to complete their tasks, external team members also have their set of tools that are unknown to you and must be able to communicate and or interface with your team’s tools and the environment to succeed.

Given the broad landscape of available tools in the professional PCB design & engineering market, it is essential to have tools that can interface across that broad spectrum seamlessly. Altium Designer provides such an environment. Beyond that, Altium Designer is not a tool just for engineers, the unified environment along with collaborative features can be tailored to any organization, be it a startup or a global organization. Altium Designer provides a licensing environment that is flexible and can be adapted to any organization’s needs.

USEFUL LINKS:

LICENSING

Altium Designer LicensingAltium Designer Licensing System

COLLABORATION

Getting Started with Collaborative PCB Design

ALTIUM DESIGNER FREE TRIAL

https://www.altium.com/free-trial