Stay Ahead of PCB Project Deadlines with Advanced Harness Design Tools

If you’ve worked on complex electronics products, you’ve likely experienced the crunch that happens when PCB harness design becomes the bottleneck. Deadlines approach, last-minute changes roll in, and suddenly your team is stuck reconciling cable drawings, connector pinouts, and outdated documentation. All while trying to keep the project on track.

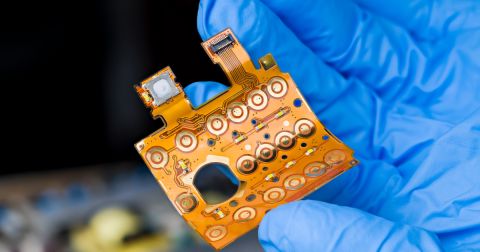

Modern electronic systems become more integrated and harness design is no longer a back-end task. It’s an important part of the electrical system that directly affects performance, manufacturability, and delivery timelines. Yet many teams are still managing it with disconnected tools and workflows that simply can’t keep up.

At Altium, we understand the challenges engineering teams face. That’s why we’ve built powerful, integrated harness design tools into Altium to help engineers stay ahead of change, avoid costly errors, and hit their deadlines with confidence.

The Problem with “Old School” PCB Harness Design

For too long, harness design has been treated as an afterthought, handled in isolation, often with generic drawing tools or spreadsheets. These methods might have worked in simpler times, but today they introduce real risks:

- Manual entry leads to mismatched data.

- Changes ripple through documentation late in the game.

- Mechanical and electrical teams fall out of sync.

- Manufacturing receives incomplete or inaccurate files.

These issues don’t just slow things down. They cause delays, rework, and missed milestones. One effective way to address these challenges is by adopting integrated PCB harness design platforms that automate data flow and enforce rule checks, significantly reducing the risk of human error and process bottlenecks.

Modern PCB harness design tools help teams stay ahead of tight project deadlines by replacing manual, disconnected workflows with digital ones. For instance, Mercedes-Benz Cars reported up to 20% reduction in development time after implementing a fully digital approach to wiring harness design using a 3D master method. While Altium’s solution focuses on 2D intelligent harness design within an integrated electronics design environment, the underlying principle is the same: eliminating drawing duplication, improving data flow, and automating documentation processes all contribute to faster, more reliable development cycles.

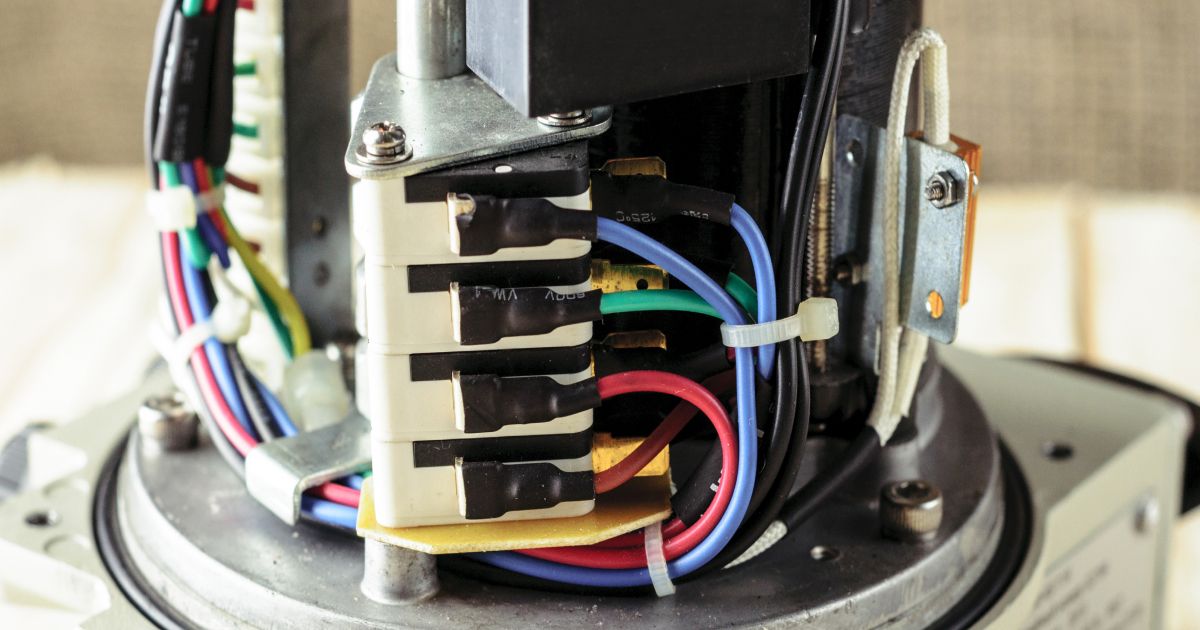

PCB Harness Complexity Is No Longer Optional

In nearly every industry, from automotive and aerospace to medical and consumer devices, wiring harnesses have grown in complexity. More functionality means more boards, more interconnects, and stricter constraints on weight, space, and signal integrity.

Electric vehicles, for example, require high-voltage lines, redundant power paths, and shielded cables to support powertrains, autonomous systems, and infotainment; all in a lightweight form factor. Even in traditional embedded systems, demands for modularity and fast product refresh cycles mean engineers are building products that have to scale, adapt, and still be manufacturable.

This landscape is making the old ways of working (manual harness drawings, siloed mechanical/electrical workflows, disconnected data) increasingly unsustainable. Teams need tools that not only keep up, but help them move faster and smarter.

Modern PCB Harness Design Tools for Modern Teams

Altium’s advanced PCB harness design capabilities are built to solve the problems head-on. Here’s how we’re helping teams stay on schedule without sacrificing quality.

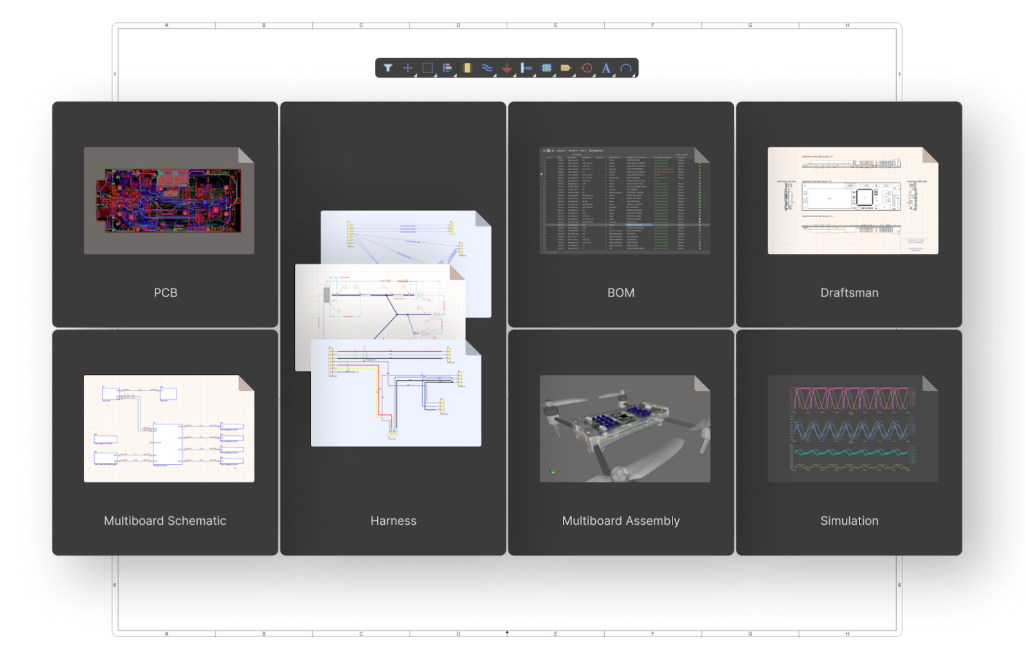

1. PCB Design and Harness Design, Together in One Workflow

No more jumping between tools or manually syncing harness data with your PCB layout. In Altium, you can define and manage your harness designs alongside your PCB projects in a single, integrated environment. When changes happen, everything stays connected, from schematic to harness to board.

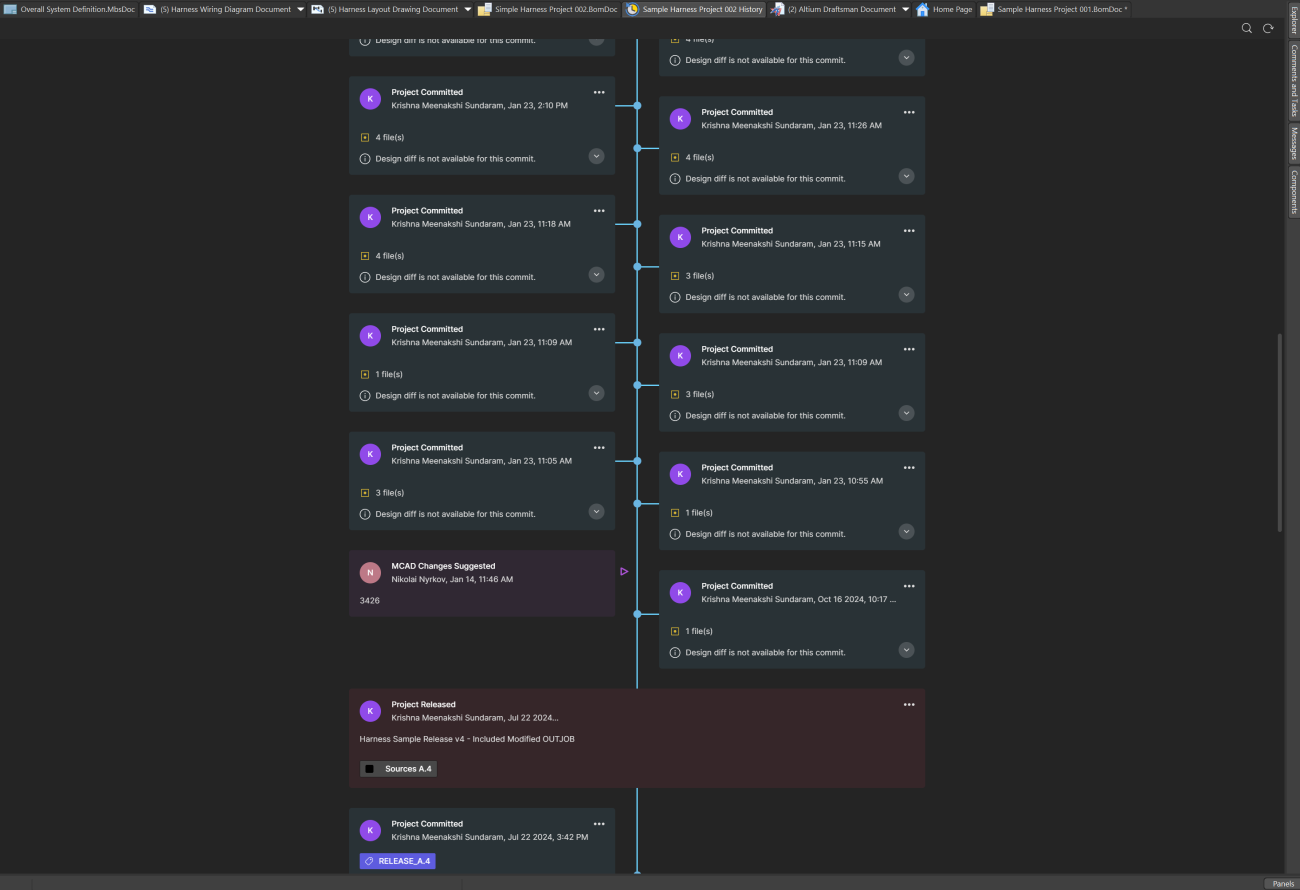

2. Cloud Collaboration for PCB Harness Designs

With Altium, your team can work from anywhere while staying completely in sync. Engineers, designers, and stakeholders always have access to the latest design data which means no more emailing files or wondering who has the most up-to-date version. Collaboration is seamless, and decisions get made faster.

3. Automatic, Accurate PCB Harness Design Documentation

Creating production-ready harness documentation no longer needs to be a time-consuming task. Our tools automatically generate clear harness schematics, wiring tables, and pinout reports, reducing the manual effort needed to prepare manufacturing outputs.

4. PCB Harness Designs: Build on What You’ve Already Done

When you’ve already designed a harness configuration that works, why start over? Altium makes it easy to duplicate and adapt existing PCB harness designs, including connector definitions, cable structures, and formatting standards. This gives your team a major head start on future projects and ensures consistency across your product lines.

Altium's Advanced PCB Harness Design Tools: Designed for the Real-World Pace of Engineering

The reality is: project scopes change, features evolve, and nothing ever goes exactly as planned. The question is whether your tools can adapt quickly when they do.

With Altium’s advanced PCB harness design tools:

- Design changes are manageable, not disruptive

- Documentation is consistent, clear, and complete

- Teams stay aligned across disciplines and time zones

- Deadlines stop feeling like emergencies

We’ve built these tools for real engineering teams who are juggling tight schedules, shifting priorities, and high-stakes product launches. If that sounds like your world, you don’t need more complexity. You need tools that simplify, connect, and accelerate your work.

Ready to Get Ahead of the Deadline?

If wire harness design is slowing down your projects or keeping your team stuck in reactive mode, it’s time for a better approach.

With Altium Develop, you can bring PCB harness design into your existing workflow, eliminate costly surprises, and deliver confidently. On time. Every time.

Explore our PCB harness design capabilities. Let’s keep your projects moving and your deadlines behind you.

Back

Back