Wire Harness Design for the Circular Economy: Designing for Disassembly and Reuse

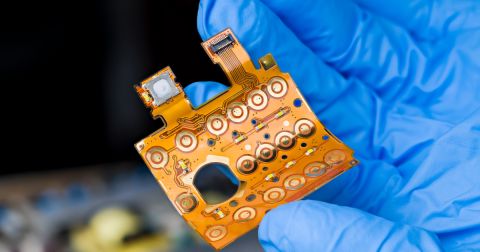

As industries embrace sustainability, hardware teams are under pressure to rethink how products are designed, built, and disposed of. Much attention is given to batteries, PCBs, and packaging, but there’s one, often-overlooked, component that has a significant role to play: the wire harness.

Wire harnesses are central to the function of almost every electronic system, from electric vehicles and appliances to industrial machines and smart devices. But when it comes to end-of-life disassembly, refurbishment, or recycling, they're also among the most challenging elements.

In this post, I'll explore how harness design impacts product sustainability and how you can align your development process with the principles of the circular economy, not by overhauling everything, but by adopting more innovative, forward-thinking design practices.

The Shift from Linear to Circular

Traditional product development follows a linear lifecycle:

Design → Build → Use → Dispose

In contrast, the circular economy promotes a regenerative model:

Design → Build → Use → Reuse/Repair/Recycle → Loop

In this model, products are designed for performance and manufacturability, longevity, modularity, ease of disassembly, and material recovery.

Wire harnesses play a key role in this shift. They can either make circular design easier or get in the way, depending on how they’re built.

Why Wire Harnesses Pose Sustainability Challenges

Unlike PCBs or batteries, wire harnesses are often:

- Deeply embedded in enclosures

- Custom-shaped to non-standard geometries

- Fastened with permanent clips or adhesives

- Lacking modularity for part-level replacement

This makes them difficult to:

- Disassemble without damage

- Sort and recycle by material type

- Reuse in remanufactured products

- Repair when only one section is faulty

The result? Harnesses often end up as waste, even if the rest of the product is recyclable.

Designing Harnesses for Circularity

Designing for the circular economy doesn't mean sacrificing performance or innovation. It means embedding end-of-life thinking into early-stage design decisions.

Here are the key principles to guide your harness design process.

1. Design for Disassembly

- Use fasteners that allow for easy harness removal (e.g., snap-fits, removable clips, non-permanent adhesives).

- Avoid routing wires through sealed compartments unless absolutely necessary.

- Separate high-voltage, signal, and power harnesses for easier identification and handling.

Pro Tip: Document disassembly paths as part of your design package. It helps service teams and supports regulatory compliance.

2. Use Modular Harness Segments

- Instead of one large, custom-fitted harness, design using modular harness sections that connect via standard interfaces.

- Modular harnessing makes replacing, upgrading, or reusing specific system parts easier without scrapping the entire assembly.

Example: In automotive applications, front-end and infotainment harnesses are increasingly modular to support platform reuse across models.

3. Enable Material Separation

- Choose wire insulations and jackets that are identifiable and separable for recycling.

- Avoid mixed-material connectors unless clearly labelled or designed for separation.

- Provide wire color codes and labelling that align with recycling standards in your target market.

4. Design for Repairability

- Allow access to connectors and junctions without disassembly of the entire product.

- Use harness routing paths that make sense for maintenance workflows.

- Document wiring logic, pin mappings, and harness structures clearly and store this data digitally, not just as PDFs.

Insight: Digital harness design tools like Altium's allow teams to maintain precise records of wire lengths, connections, and schematics, which improves supportability and traceability post-production.

5. Support Data-Driven Sustainability Reporting

With increasing regulations like the EU’s Ecodesign for Sustainable Products Regulation or Extended Producer Responsibility (EPR) policies, OEMs are expected to track and report material content and recyclability.

Harnesses designed in a connected, intelligent system can feed into these reports, enabling easier declarations of:

- Recyclable copper content

- Plastic composition in connectors and jackets

- Critical raw material use (e.g., rare metals in shielding or coatings)

Having this data available as part of your PLM or design platform reduces friction during audits or certifications.

Digital Design in Sustainable Harness Engineering

Much of circular design starts with information: knowing what materials are in your product, how components interact, and what changes have occurred over time. Without that visibility, disassembly and reuse become guesswork.

This is where digital harness design tools, particularly those integrated into your PCB and system workflow, make a measurable difference. Tools like Altium bring harness development into the same environment as board and schematic design. They support centralized libraries of connectors, wire types, and materials, while enabling automated documentation, traceable design history, and consistent output generation.

When combined with a circular design mindset, these tools empower teams to:

- Visualize disassembly impact before manufacturing begins

- Validate modular harness layouts in the early design phase

- Capture sustainability-relevant metadata (like material types or reuse flags) without additional manual work

These improvements go beyond daily operations and directly contribute to long-term goals in sustainability and product lifecycle management.

Circularity as a Competitive Advantage

Sustainability isn’t about just about compliance anymore. It’s a powerful way to stand out in the market. Leading OEMs, like Volkswagen Group or Volvo Cars, are already putting these principles into practice by:

- Designing harnesses for second-life reuse, especially in refurbished or remanufactured products

- Simplifying wire routing to support automated or manual disassembly workflows

- Standardizing interfaces and segments to enable easier field repair or sub-assembly replacement

- Using measurable sustainability metrics (e.g., recyclability rates, modularity scores) as part of product marketing and compliance documentation

Applying circular design principles to harnesses can:

- Reduce environmental impact

- Improve product longevity and serviceability

- Lower end-of-life processing and recycling costs

- Support brand commitments to ESG (Environmental, Social, and Governance) and net-zero goals

Final Thoughts

It might not grab the spotlight, but the wire harness can make all the difference when it comes to hitting your sustainability goals.

By designing harnesses for reuse, disassembly, traceability, and material separation, engineering teams can align with circular economy principles and create functional and future-friendly products.

With the right digital design tools, building this into your process doesn't have to mean more effort, just smarter, more intentional decisions from the start.