Securing Early Access to Cutting-Edge Components

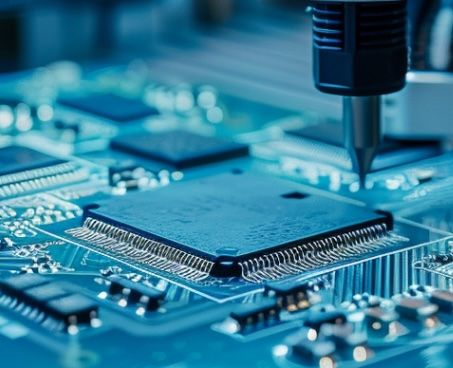

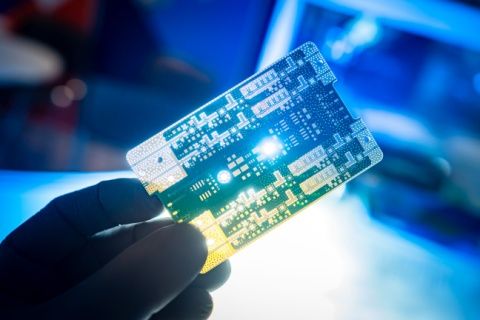

Historically, PCB designers have faced the ongoing challenge of finding the right component for whichever purpose their eventual manufactured PCB will serve. With supply shortages, poor quality parts, and unreliable vendors filling the space, that has proven troublesome. Today, with the oversaturation of the tech market and growing consumer demand for bigger and better, designers now face an even more difficult task: sourcing cutting-edge components.

And that begs an important question: how do PCB manufacturers secure early access to the top-quality components that power the plethora of devices and gadgets we have at our disposal?

Here are the key ingredients for the recipe to success.

Build Strategic Partnerships

Building solid relationships with both distributors and component manufacturers helps companies to create a resourceful network that can give a significant edge over the competition. Here’s how:

Direct Manufacturer Engagement:

The fastest way to secure early access to new components is via direct communication with the engineering team at a manufacturer. A direct line to the source, expressing interest in their upcoming technologies, demonstrates your company's commitment and helps you stand out from the many potential customers. In some cases, designers can participate in surveys or early-access programs that can further solidify your position as well as help drive the development of these new products.

Through these platforms, if you’re offered a Non-Disclosure Agreement (NDA), the manufacturer can share some confidential information about upcoming technologies and application support, including detailed technical specifications, datasheets not yet publicly available, design examples, and potential compatibility issues with existing components that your designers might be using.

Proactive Industry Intelligence Gathering

Events and Conferences:

Trade shows and conferences are prime hunting grounds for uncovering new and conceptual components. Often, these events have early demonstrations and prototype discussions that can grant you a glimpse into the future of component tech. Look for technical deep dives focusing on emerging components and their potential applications; attending these sessions allows designers to better understand the technical intricacies, performance characteristics, and possible design challenges associated with these cutting-edge parts. Some events also provide hands-on workshops for interested parties to gain practical experience with pre-release components. This is an invaluable experience. Designers can explore the functionalities first-hand, test integration with existing tech, and troubleshoot potential issues before full-scale production begins.

News and Online Communities:

Knowledge is power. Subscribe to industry publications, relevant company blogs, and online forums to stay updated on upcoming component releases and technological advancements. You can extend this to business social media like LinkedIn, where you can follow industry leaders who often provide valuable insights into future trends. For the best results in this domain, try not to fall into the silent majority. Don’t be a passive observer; participate in discussions, share your expertise, and build a reputation within the field to attract potential partners and providers further down the line. This is a proactive, social approach that many—especially engineers—shy away from but could position you to identify and capitalize on emerging trends before they become mainstream.

Scenario Planning:

Businesses should always anticipate potential roadblocks and develop contingency plans—especially when it comes to budget allocation and resources available. Early access components often come with higher costs and more potential for technical challenges than long-term tried-and-tested ones. Factor these considerations into the budget and development timelines. Here are some specific examples:

- Limited Availability: Early access components might have limited production runs initially, which impact the quantity companies can secure. Be prepared to adjust your production volume or find alternative sourcing options.

- Potential Design Iterations: Technical specifications and datasheets for pre-release components are often subject to change. This could necessitate design modifications or additional prototyping before finalizing your PCB layout.

- Integration Challenges: Integrating cutting-edge components with existing technologies isn’t always as easy as plug-and-play. Thorough testing and potential design adjustments might be required for optimal operation.

While not an exhaustive list, these strategies, when implemented, can help PCB designers secure early access to the latest components and assist in the development of flagship devices. Remember, the race for the cutting edge is more of a marathon than a sprint; it takes a lot of preparation. Building strong relationships, proactively gathering intelligence, and designing PCBs with flexibility in mind are absolutes that should not be ignored in pursuit of the industry gold standard. While there will be challenges, the rewards of being first-to-market with the very best PCBs and devices are, without a doubt, worth it.