Are Your SMD Components Reliable for Aerospace?

Aerospace systems are the one area that demand paramount reliability, both in the commercial and military segments. These systems can operate over a huge range of temperatures, pressures, and altitudes, including in Earth’s orbit and beyond. As such, there is an expectation of perpetual uptime for aerospace systems, as well as long lifetimes with MTBF values exceeding 10,000 hours of continuous operation.

SMD parts used in these environments, particularly integrated circuits and passive components, need to meet certain materials, construction, and testing requirements to ensure the full lifetime of the components can be realized. Before building the BOM for your aerospace system, make sure you understand how parts are qualified for flight.

Component Factors That Compromise Reliability

Materials

Materials need to be strong enough to withstand large temperature swings and vibration, but there is more involved in materials used in electronic components. Any of these factors can lead to early failure of components when a design is ready for flight:

- Thermoplastic materials need to be tested for outgassing if a product will be deployed at very high altitudes (low pressure) or vacuum environments.

- Metals with high vapor pressure, such as zinc and cadmium, should not be deployed in vacuum environments as these metals will sublimate. Nickel plating can be used to prevent sublimation, but this should be verified with some testing.

- Components containing pure tin and some tin-based platings on components can undergo whiskering during flight. This creates risk of shorts as whiskering grows over time.

Metal Component Body

A component with a metal casing or enclosure is typically mechanically stronger than thermoplastic components, but the metal body will create a danger of shorting or arcing as altitude increases. This occurs because the dielectric strength of air decreases as altitude increases due to the reduced density of air at higher altitudes. As a result, any electrical equipment or electronic device operating at high altitude may require a higher Basic Insulation Level (BIL) or larger clearances between conductors to compensate for the lower dielectric strength.

In fact, if you look at the IPC-2221B standard for clearance and creepage, you will see that the standard defines a conductor spacing requirements as a function of DC/peak AC voltage. If you look at Table 6-1 and compare columns B2 and B3, you will find that the large difference between these values is based on the elevation where the board is deployed (see the footnotes in the image below).

IPC-2221B conductor spacing requirements. Learn more in this article.

Note that column B4 and A5 specify clearance values for two coated conductors at any elevation, and this offers one solution to the higher clearance requirements for uncoated conductors at high altitude. The problem is that the coating could outgas, similar to the thermoplastic material issue listed above. Any coating, potting material, or encapsulant should be tested for outgassing before use.

Structural Support

Integrated circuits and SMD passives are not slabs of material, they have an internal structure that determines their mechanical reliability. If a component does not have sufficiently strong internal structure, the component can fail at low pressure or high pressure. Just like the research results I discussed in another blog on high-pressure electronics, the same group of components could fail at low pressure. Testing in a HV/UHV environment for extended periods and subsequent inspection can be used to identify components which will fail at low pressures.

Vertical Offset Parts

Some parts may not sit flush against landing pads, or there may be large space between the part and the PCB. This creates a risk of large amplitude vibrations during flight, leading to solder fatigue and failure of the assembly.

To address this problem, a spacer or filler compound may be required under the part to fill excessive part-to-PCB gap. The filler compound can be an epoxy or a small plastic spacer, but the support will need to be qualified for outgassing and thermal reliability. Epoxy filler can be difficult to work under small components; consult with a MIL-SPEC compliant PCB assembler about their capabilities and process for applying a spacer or underfill for these components.

Landing Pads

High-density assemblies can be difficult to design and assemble to Class 3/3A standards, which is required for aerospace electronics. The land pattern must be designed to ensure a sufficiently large solder fillet forms on the exposed leads. Similarly, the leads need to be large enough to hold a sufficiently large fillet. If neither condition is met, there may not be enough solder to withstand mechanical shock or vibration during flight.

In the case where the solder fillet on the component lead ends up being too small (or vice versa), an adhesive could be used to help fixate the part to the PCB. If the parts in question create a lot of heat, a 2-part epoxy or other adhesive may degrade at high temperatures. Instead, a thermal paste could be used on the part as this will provide adhesion and heat transfer with a single material. Outgassing of these materials needs to be tested, and the strength of the bond should be tested.

Obtaining MIL-SPEC Components

Components that are designed to withstand tough conditions found in aerospace are normally marketed as MIL-SPEC components, in reference to the Military Specification standards set by the US Department of Defense (DoD). Many SMD component vendors, such as Vishay and Kemet, offer a line of MIL-SPEC components which may not be available through commercial distributors like Digi-Key or Mouser. Instead, customers will need to contact the vendor directly to obtain the components.

As part of a data package for these components, vendors can provide test data which proves reliability in various operating conditions, ranging from large temperature swings to vibration and vacuum environments.

If a component is not specifically qualified for MIL-SPEC, it could still be used for aerospace as long as it can be proven to be reliable in flight. This involves a range of stress tests, some of which are discussed above. You can also check out the following resources:

- The High-Reliability PCBA Design and Test Challenge

- Overview of PCB/PCBA Reliability Testing and Failure Analysis

- What is Burn-in Testing for Electronics?

- Designing with Shock Management for Avionics PCBs

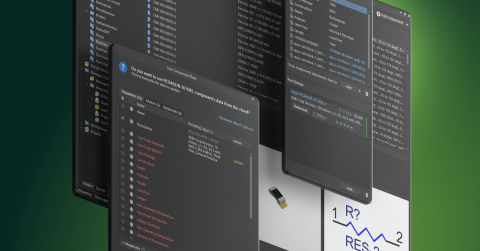

Whether you need to build reliable power electronics or advanced digital systems, use the complete set of PCB design features and world-class CAD tools in Altium Designer®. To implement collaboration in today’s cross-disciplinary environment, innovative companies are using the Altium 365™ platform to easily share design data and put projects into manufacturing.

We have only scratched the surface of what’s possible with Altium Designer on Altium 365. Start your free trial of Altium Designer + Altium 365 today.