The High-Reliability PCBA Design and Test Challenge

High-reliability electronics must go through multiple rounds of testing and qualification to ensure they can withstand their intended operating environment. Designing to performance standards, whether the baseline IPC standards or more stringent industry standards, is the first step in ensuring a reliable circuit board can be manufactured with a high yield and will perform as required in its ideal environment. Over several rounds of prototyping, design and test teams will have to stress designs to their limits to see how much stress they can withstand during operation.

Once failures in high-reliability systems are observed, boards must be examined and inspected in order to identify and eliminate root failure causes. The exact strategy involved in failure analysis depends on the system being designed and its operating environment. Design teams should have a thorough understanding of the testing requirements placed on fabricators, assemblers, and test engineering teams so that comprehensive reliability assessments can be performed.

In this e-book, readers will gain a thorough look into PCB testing and analysis, starting from basic tests performed on bare boards and completed assemblies. Covered topics include:

- Some common failure mechanisms and how these can be identified

- How manufacturers can take steps to assess the reliability of a PCBA

- Electrical stress test methods

- Where thermal challenges exist in a PCBA

Click the PDF above to read more about PCB reliability and testing. You can also read the original, full-length content here:

PCB Testing 101: Important Methods and Metrics

What is Burn Testing of Electronics?

Overview of Electrical Stress Test Methods for PCBAs

Overview of PCBA Reliability And Failure Analysis

PCB Thermal Analysis Software

About Author

About Author

Zachariah Peterson has an extensive technical background in academia and industry. He currently provides research, design, and marketing services to companies in the electronics industry. Prior to working in the PCB industry, he taught at Portland State University and conducted research on random laser theory, materials, and stability. His background in scientific research spans topics in nanoparticle lasers, electronic and optoelectronic semiconductor devices, environmental sensors, and stochastics. His work has been published in over a dozen peer-reviewed journals and conference proceedings, and he has written 2500+ technical articles on PCB design for a number of companies. He is a member of IEEE Photonics Society, IEEE Electronics Packaging Society, American Physical Society, and the Printed Circuit Engineering Association (PCEA). He previously served as a voting member on the INCITS Quantum Computing Technical Advisory Committee working on technical standards for quantum electronics, and he currently serves on the IEEE P3186 Working Group focused on Port Interface Representing Photonic Signals Using SPICE-class Circuit Simulators.

Related Resources

Related Technical Documentation

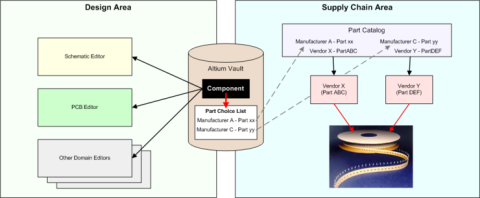

Multidisciplinary Product Creation

- Align data and context across every discipline

- Collaborate concurrently with no silos

- Make faster decisions with shared visibility

- Stay connected through real-time updates

Learn More