A Big Kick in PCB Interconnect Solutions: Multi-Board Best Practices

In today’s world of densely packed components (HDI), advanced manufacturing capabilities, and wonky product shapes, you may find yourself at a loss for horizontal real estate and looking into vertical space. When a PCB gets too dense or overly complex, the designer may start looking to external modules or add-on boards to fill the product enclosure. Adding these additional PCBs creates a multi-board system that must be verified for connectivity and mechanical fit. Best practices for ensuring both revolve around the design process and workflow, ensuring best practices for these systems are implemented. Success in multi-board design and best practices for designing systems focus on multiple areas:

- Mechanical fit and board arrangements

- Electromagnetic compatibility (EMC)

- Power handling and power integrity

- Signal integrity on board-to-board interconnects

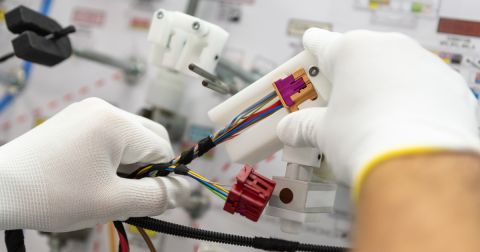

Whether it be your consideration of space within a product or keeping signals isolated from one another, you’ll likely need your boards to talk to each other. Enter board-to-board interconnects: the practice of running physical, non-printed cables between multiple printed boards in order to achieve a fully connected circuit.

Four Areas for Best Practices in Multi-Circuit Board System Design

Mechanical Fit and Rugged Design

One of the main reasons to use a multi-board system is to push components onto a separate circuit board, which will free up additional space in the enclosure. The connection between each PCB in the system and the orientation of each PCB has to be modeled to ensure proper fit within the enclosure. The board-to-board interconnection must also be able to withstand the environment where the system will be put into service.

When selecting connectors for a board-to-board or board-to-wire connection, start by balancing these factors against the mechanical strengths of the system design:

- Current value per pin

- DC or AC isolation and breakdown voltage ratings

- Temperature rating

- Number of mating cycles and pin plating material

- Locking or retention mechanisms

- Pulling force before disconnect

- Wire attachment method for board-to-wire connectors

These connector specifications will determine how rugged your multi-board system will be and the type of environments where it can operate.

Checking the form and fit in an MCAD application is also helpful in ensuring that the design will fit in its enclosure. However, not all designers have access to this type of software. It is still possible to verify the form and fit with selected connectors using inexpensive prototype boards or bare PCB materials. You could also use sheets of plastic or cardstock to arrange boards in an enclosure. To prototype the enclosure, 3D printing with plastic filaments is one option that will give a very good estimate of available space in the enclosure.

Early prototyping to estimate board size and dimensions is always a good idea. At some point, a mechanical engineer needs to get involved to simulate the placement of the final design. This will need to happen in MCAD software, as it allows all of the 3D elements in the PCB layout to be simulated for form, fit, and function.

A 3D-printed enclosure can be used to prototype a multi-circuit board assembly.

Power Handling and Power Integrity

Power integrity is normally brought up in the domain of high-speed digital designs, where we want to ensure low-noise power reaches digital power pins on large processors. In a multi-circuit board design, power can be passed between circuit boards, which is typically provided as line AC voltage or a DC voltage from a power supply board. Power integrity in this context refers to low-frequency AC or DC power integrity, where we want to minimize resistive loss along the board-to-board interconnects.

To ensure appropriate power handling in board-to-board interconnects, connectors and cabling should meet several important specifications:

- Low contact resistance and sufficient current limits on connector pins

- Additional capacitance, LC filtering, or higher-order low-pass filtering on power pins

- Circuit protection, such as TVS diodes or charge collector circuits for surge protection

- Sufficient copper at the connector lands on each PCB

- High enough pin count for handling the total required current

Once on the destination PCB, power integrity will be determined by the power supplies and distribution networks on the receiving boards.

Filters and capacitance were mentioned in the above list. As far as placement of these circuits is concerned, they should be placed close to the connector for the board-to-board interconnect. This ensures the filter has a chance to remove any noise from the power lines before making a connection to the wiring. The same applies to circuit protection, which should be placed closer to the connector and before any branches in the power distribution network.

Signal Integrity

From a high level, signal integrity in board-to-board interconnects relates to impedance matching and providing a reference conductor for signals on the PCB interconnect. In many connectors, wiring is bundled together or arranged in a ribbon cable format. Therefore, for each signal conductor to have its own reference conductor, many of the pins on the board-to-board connector will need to be tied to ground.

This is one reason why high-speed board connectors have so many pins and why the pins can have a very fine pitch. Some connectors can have a BGA-style mounting, where the connector solders onto an array of SMD pads on a PCB. Allocating approximately half of the available pins to ground and interleaving them in the pinout will provide reference conductors for each pin, which will then capture the return current for each signal on the board-to-board interconnect.

Snapshot of a high-density board-to-board connector pinout (PN: ASP-134488-01). Note how the ground pins interleave between these high-speed signal pins, which include single-ended and differential signals.

Finally, connectors designed to carry large numbers of signals will have a data rate specification (equivalent to a bandwidth specification) or a rating for a specific interface. These specifications effectively indicate the channel bandwidth that a board-to-board interconnect can provide. Make sure to allow some headroom for your interface when selecting a connector, and use the vendor-provided Touchstone file to simulate the S-parameters of the full interconnect for verification purposes.

EMI and EMC

EMC can already be quite challenging for many board designers, especially given the high failure rate for first-pass EMC testing or pre-compliance testing. Having multiple PCBAs in a multi-board system can make things more complex, and locating sources of EMI can be more difficult than in a single PCBA. The boards themselves and the PCB interconnects can be sources of EMI and contribute to EMC failure. In addition, boards that individually would not fail EMI testing may suddenly fail once put into a multi-board assembly, highlighting how the PCB interconnects can be a point of failure.

So, what are some practical steps that can be taken to prevent EMI problems early? Individual PCBs should still follow best practices for preventing radiated and conducted EMI. There are some initial steps that should be taken to address the source of EMI from a board-to-board interconnect: unintended conduction of currents along wiring in the PCB interconnect.

- As mentioned above, use filtering, particularly both differential and common-mode filter circuits.

- Add a sufficient number of ground wires to board-to-board interconnects.

- On some circuits, common-mode chokes can be used when other filter circuits are not appropriate.

- If shielded cabling is not needed for ESD or susceptibility reasons, do not include it on a cable or wire harness.

- Additional components for reducing system-level radiated emissions include EMI gaskets or shielding compounds.

Standard components for filtering common-mode and differential-mode currents come in an SMD module format. One example is the integrated fifth-order filter circuit shown below from Murata, which I recently used in the flyback converter module project on Altium Academy.

This 5th-order low-pass filter module from Murata (PN: BNX026H01L) is placed close to the output board-to-wire terminal block.

These EMI reduction options, along with designing the individual boards correctly, can eliminate many common causes of EMI failure. Many of the more complex EMI failure mechanisms involve issues with grounding, often in relation to chassis or shielding, so understanding grounding is quite important.

Whether you're building reliable power electronics or advanced digital systems, Altium provides a complete set of PCB design features and world-class CAD tools. To enable collaboration in today’s cross-disciplinary environment, innovative companies use Altium to seamlessly share design data and accelerate projects into manufacturing.

Interested in exploring multi-board PCB design? Discover how Altium Develop makes it easy to create complex designs and error-free system interconnections.