Overview of the Gerber X3 File Format

Most designers and EDA vendors are probably unaware of the most recent update to the Gerber export formats from Ucamco. Quietly in 2020, Ucamco released an update to the Gerber format, with the new format known as Gerber X3. The new format looks a lot like the format, and unless your EDA software or CAM tool told you that you had a set of Gerber X3 files, you probably wouldn’t know it.

So what’s the big deal with this format, and why should designers and manufacturers care about it?

When we look at some of the new features and metadata available to be included in Gerber X3 file exports, it’s much clearer why Ucamco opted to perform this upgrade to the industry’s de facto manufacturing file format. I’ll outline some of the upgrades and new features in this article.

History of Intelligent Data Formats

First, I’ll give you a very brief overview of PCB manufacturing outputs, and hopefully this will illustrate the motivation for updating the Gerber file format to its current version.

Gerber files date back to 1980 with the original release of the RS-274-D file format; later in 1998, the format would be declared “technically obsolete” and it was replaced with the RS-274-X format, which remains the de facto standard to this day along with Gerber X2. In 1995, the first “intelligent” data format known as ODB++ was released as an attempt to bundle more fabrication and assembly data into a single data archive for handoff to PCB manufacturers. In March 2004, the original revision of the IPC-2581 standard was released, providing the same level of intelligence as an ODB++ output but in a single XML-based file (.IPC extension).

Click to learn more about today’s PCB output file formats

EDA vendors and CAM vendors have since supported the creation and viewing of these data formats to varying degrees. The trend in the evolution of these file formats should be clear: they have steadily incorporated more information about the PCB into the format as time has gone by. Some examples of supported data in these file formats includes:

- Component information

- Stackup and layer definitions

- Net names without the need for an external netlist (like IPC-D-356)

- Differential pair definitions

There have been other modern formats that have come and gone, which Happy Holden details nicely in another article. But the three that have survived so far are newer Gerber versions, ODB++, and IPC-2581. X3 brings the classic Gerber format much closer to what you would expect to see in an intelligent data format.

What’s New in Gerber X3

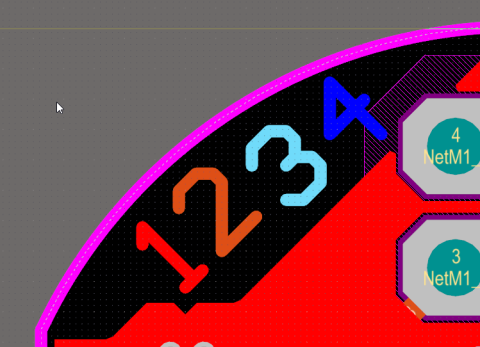

Gerber X3 still exports a batch of files that encodes the manufacturing data, with one file exported per layer. The new X3 format brings the ability to encode component and assembly data into a Gerber export which would normally require an additional set of PCB design exports. The new Gerber X3 format supports inclusion of the following information:

- Explicit definition of top and bottom placement layers

- Component reference designators

- Component manufacturer/internal part numbers

- Component placement details (location and rotation)

- PCB library details (footprint name and package details)

- Component outline dimensions

- Component pin locations

- Backward compatibility with earlier software maintained

The benefit for designers is quite clear: the format has the potential to eliminate the requirement for a separate PCB design outputs that would normally be handed off to assembly. The two big integrations into a Gerber export are the bill of materials and pick & place files. This could help prevent some of the common issues arising in PCB fabrication and assembly, such as a footprint mismatch between fabrication and BOM data.

What’s Not in Gerber X3

To see what’s not available in Gerber X3, one needs to only look at the ODB++ format as it is the closest competitor to Gerber X3 in terms of file structure and breadth of information. Gerber X3 still does not contain the following information which is already encoded in an ODB++ archive:

- PCB materials definitions in the layer stack

- Layer number/order in the PCB stackup

- Differential net definitions

Unfortunately, this means any CAM-based analysis requires defining the layer stack manually and arranging them into the appropriate order. CAM users will have to do this as part of process planning and performing a DFM review for customer orders. Gerber files allow export of mechanical layers or drawing layers, and it is common practice to put a layer stack drawing and impedance table into a Gerber layer (usually the drill drawing layer).

For more information about the Gerber X3 format and the syntax required to encode this information in component layer files, read the 2020.03 revision of the format from Ucamco. This document lists all syntax and provides example files showing proper usage of each command.

Whether you need to build reliable power electronics or advanced digital systems, use the complete set of PCB design features and world-class CAD tools in Altium Designer®. To implement collaboration in today’s cross-disciplinary environment, innovative companies are using the Altium 365™ platform to easily share design data and put projects into manufacturing.

We have only scratched the surface of what’s possible with Altium Designer on Altium 365. Start your free trial of Altium Designer + Altium 365 today.