Power Supply PCB Design

Power supply layouts are a common source of EMI, both in terms of conducted and radiated emissions. The emissions from a power supply PCB layout can be solved with a few basic principles, which apply for isolated and non-isolated power supplies. The layout practices are often buried in datasheets or somewhat implemented in development boards, but it can be difficult to separate best practices for low EMI from the arbitrary practices implemented by inexperienced dev board designers.

That's why we created this guide: to provide PCB design and layout guidance for power supplies that are EMI aware. These power supplies also tend to have very strong power integrity, as the power quality problems experienced on power rails often become sources of EMI, especially on power rails for large digital processors. Throughout this guide, I will link to other resources that help you understand why we can implement certain choices in power supply design and why some design decisions are outdated.

Common Power Supply Characteristics

Power supplies in today's modern PCBs are always pushing the limits of power density and feature density. They operate at higher frequencies, broader control loop bandwidth, and with more integrated features than in systems of the past. Power supplies are both an electrical system, due to the topology of the power regulator circuitry, and there is an element of mechanical design present in the systems due to the enclosure and thermal management requirements.

PCB layout should take all of these factors into account. However, this is not all that is implemented in the PCB layout. There are also safety and reliability standards which impact power supply PCB design, including IPC standards, industry-specific standards, and safety requirements to protect against exposing the user to dangerous currents.

Important Design Standards for Power Supply PCBs

There are many industry standards that apply to power supply PCBs, ranging from IPC standards to other industry-specific standards. Two of the basic IPC standards that will ensure your power supply does not experience ESD or excessive temperature rise in conductors are:

- IPC-2221: This general design qualification standard applies to power supply designs by specifying creepage and clearance requirements. These requirements are meant to help prevent ESD between exposed conductors on the surface layer and between conductors on internal layers. Learn more about designing to IPC-2221 standards in high voltage designs.

- IPC-2152: This standard applies to current carrying capacity in conductors with the intent of limiting temperature rise in conductors. This limit should be used to size polygons, copper pour, power planes, and power rails on the surface and internal layers. Learn more about sizing conductors in your PCB layout to ensure low temperature rise.

Other important IPC standards will govern reliability, such as IPC-6012 and IPC-A-600, which may classify a power supply design as Class 2 or Class 3. UL/IEC standards are also important in multiple industries as these will specify safety requirements on a range of products.

Power Supply and Regulator Topology

A correctly designed PCB, including the PCB stackup and layout, can support any of the common types of power supplies or power regulators:

- Isolated power supplies

- AC-only, AC/DC converters, or DC/DC converters

- Multi-output power regulators

- Multiple power regulators in the same PCB

- Prepackaged SMD or through-hole power supply modules

- Switching at high frequencies for regulated DC output

- For adjustable AC supplies, multiphase bridge topologies with switching stages

Within these different types of power supplies are specific circuit topologies. Learn more about standard power converter topologies.

It's not uncommon to see a mixture of these different types of power supplies or multiple regulator circuit topologies in the same PCB, or in the same multi-board assembly as separate modules. Before starting the PCB layout and routing power rails, we need a suitable PCB stackup that will support the required thermal demands, voltages, and clearances/copper weight in the design. Your design also might benefit from an alternative PCB stackup material, such as a ceramic or metal-core PCB.

PCB Stackup for Power Supplies

The PCB stackup for a typical power supply or power regulator module can be very basic, particularly when the current demands and thermal demands are minimal. Standard two-layer PCB stackups are acceptable for low-power dedicated power supplies or modules. These devices do not require controlled impedance and may only require heavy copper in order to provide the required power output.

The most common situation is that the power supply on a PCB will have the same stackup as wer-the rest of the system because the design is fully integrated. Most commonly, this means the layout for the power supply is placed above a ground plane on a multi-layer PCB stackup.

Example showing 6 of the layers in a multi-layer stackup with 1 layer allocated to power rails. This is the most common practice for power rail routing in high-speed digital designs and mixed-signal designs. There could be more than 1 power plane within this layer arrangement pattern.

Power rail routing can then be done on an internal layer that is dedicated to power nets, or on an external layer spreading around the rest of the board. We may do this for several reasons:

- Placing power rails near a ground plane provides extra capacitance and low spreading inductance

- A dedicated power layer can be used for multiple rails with different voltages and currents

- Separating power layers by ground prevents a certain type of mixed-signal EMI where two planes oscillate with respect to a virtual ground

- Power rails on an internal layer may exhibit lower EMI and can still act as a reference for signal layers

Once we have an understanding of these points, we can see how some older application guides and outdated layout guidance from semiconductor vendors result in bad layout practices.

Good Power Supply PCB Design Practices

The typical switching power supply circuit consists of a controller IC, switching FETs, input and output capacitors, and passives connected to the pins on the controller IC. Most importantly, there is an inductor and/or transformer to supply some inductance in the switching current loop. Some designs may also use chokes or EMI filters on the input or output sides of the regulator circuit.

The layout and routing of these components falls into a list of typical guidelines:

|

Current loop path |

|

|

Feedback line |

|

|

Passives placement |

|

|

Switch node |

|

|

Clearances and creepage |

|

|

Material selection |

|

|

Parallel FET placement |

|

| Routing style |

|

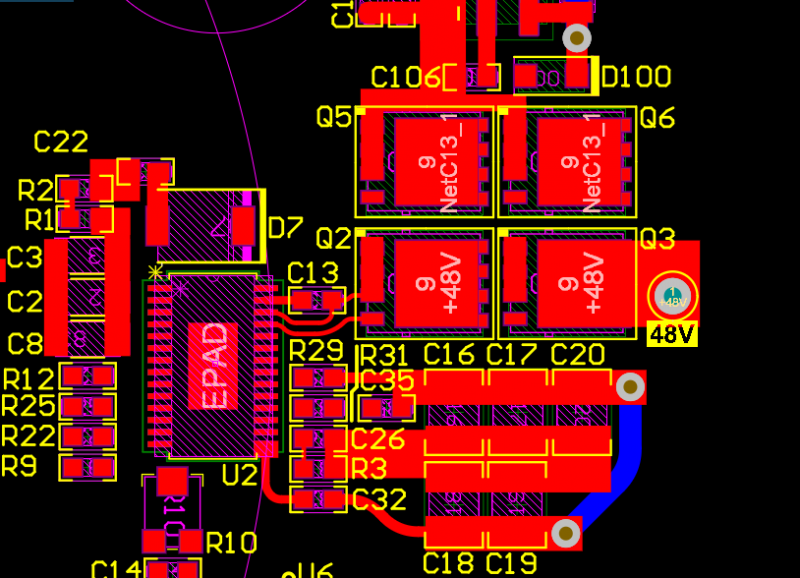

The “tight loop” guideline is not always well-defined, which leads to some poorly contextualized guidance about how to layout a power supply in a PCB. A sufficiently small loop area for the switching current path can be maintained on a single layer or by placing the components on both surface layers. How this is achieved depends on the pinout and the size of the components used. To see how this works, let’s look at an example.

Example 1: 3.3V/3A Buck Converter

A “tight” loop along the switching node to the feedback line and the output rail are shown below in an example 3.3V/3A buck converter. The feedback line comes from the output rail and wraps around the inductor to connect back to the feedback pin on the regulator (below the PGOOD pin). If the feedback line were too noisy due to coupling from the switch node, the feedback line could be routed through an internal layer.

This particular example shows how the regulator layout can be done on a single layer with small footprint. The 2D and 3D views of the layout are shown below.

This particular regulator part number (PN: TPS62903RPJR) and layout have been used in many of my projects with digital components. This part number is excellent for powering smaller systems that have multiple high-speed interfaces; the control loop bandwidth is sufficient to help maintain stable power as long as there is sufficient capacitance.

Note that the location of ground in this design is on the neighboring layer (L2). However, there is also a large copper pour in this layout; note that the copper pour is not required for the regulator to function. In this particular design in the example, the design needs copper pour on the top layer but not for the sole purpose of providing a ground connection.

Example 2: Isolated DC/DC Converter

In an isolated DC/DC converter, we have two important elements in a power supply which helps maintain stable output power and user safety:

- Separate ground planes on the input and output sides

- An optocoupler in the feedback line

These power supplies require having a clear separation between the input and output sides of the design, which normally happens at a transformer. To control the flow of high-frequency currents and prevent high-frequency EMI, you can use a safety capacitor (Y-type) that has voltage rating matching the value required for galvanic isolation (normally in the kV range).

A layout example from our flyback converter example project is shown below. Here, the galvanic isolation boundary is clearly defined beneath the transformer and we can see clear separation across the conductors on the input and output sides. Note that this design does not include a ground plane as it is a simple PCB module with DC output.

The placement of the y-type capacitor (C12) is near the flyback transformer. This ensures a low-impedance path across the isolation barrier for high-frequency currents, allowing them to close a circuit loop back to the power supply input rather than radiating away from the secondary side of the PCB layout.

Grounding and Magnetics

The examples above have shown the standard grounding method where the system has a single ground net, and another example where there is galvanic isolation between two sides of a transformer and thus two different ground nets. One of the most important factors determining the performance of your power supply PCB is how ground is defined and where it is located in the PCB. This is a matter of ensuring power stability and low EMI from switching stages in power regulators.

There is another guideline surrounding the usage of magnetics in power supply PCBs with ground planes: removing ground below magnetics. This guideline includes removal of ground below inductors in a DC/DC converter and removing ground below chokes. There has been some research on the removal of ground below magnetics and the impact on EMI and power conversion efficiency. For example, see this Signal Integrity Journal article by Ken Wyatt and Steve Sandler.

Based on Wyatt and Sandler’s results, and based on Monolithic Power Systems experimental results presented at this link, we can define a few frequency ranges where an impact on emissions can be observed:

|

Below 10 MHz |

|

|

10 MHz to ~150 MHz (LISN) |

|

|

Above ~150 MHz |

|

Older power regulators running in the 10 kHz switching frequency range would have the majority of their emissions residing in the <10 MHz range, so we can understand why the ground cutout would be useful in these designs based on the results in the table.

However, newer designs can run at ~MHz switching frequencies, and a significant amount of emissions would be confined at >10 MHz frequencies. In this case, the results illustrate that a ground cutout should not be used as it creates an opportunity for high-frequency radiated and conducted emissions from the DC/DC converter.

Bad Power Supply PCB Design Practices

There are several guidelines which are based on older power supply technology or are based on bad dev board examples and should not be followed. Some of these ideas come from mixed-signal PCB design, and others come from a misunderstanding of the role of certain filtering components and grounding strategies:

- Placing ground cutouts below magnetics/switching nodes/etc. - this always creates an opportunity for larger emissions

- Using ferrites across ground nets in isolated regulators - this eliminates galvanic isolation and creates a safety problem

- Input filter designs without safety capacitors - these components ensure there is a safe failure mode and reduce conducted emissions

- Star grounding - this confines supply noise but removes ground below signals, creating a larger radiated EMI problem

- Ferrites or filters on regulator outputs - these can reduce the bandwidth of the control loop and cause a transient to drive the regulator into instability

- Lack of circuit protection - include TVS, reverse polarity, and/or surge protection wherever there is a chance for the system to receive ESD or surges

- Heavy copper - not all designs need heavy copper; sometimes it is simpler and lower cost to use more plane layers

- Chassis ground connection - do not connect a chassis ground to a net which carries a high current as this creates a safety risk for the user of the device

- Earth ground connection - treat the earth connection as a chassis ground; it should not be used as the power supply return, only as a safety ground or dump for RF currents.

All Your Power Supply PCB Design Tools in One Application

By now it should be clear that designing safe power supplies requires multiple design tools, analysis steps, components, and simulations. To stay productive, power electronics designers need a complete set of PCB layout, simulation, and component sourcing tools, and designers can work at maximum productivity when all their design tools are in a single program.

Altium Designer’s major advantage over other ECAD applications is its integration. Everything needed to design power electronics and other advanced designs is located in a single program. You won’t need to add in external programs to finish your designs, you can do everything needed to get your board designed and manufactured with a single application.

- Altium Designer helps ensure your PCB for your power supply complies with basic industry standards with its full suite of rules-driven design features.

Learn more about the complete set of PCB design tools in Altium Designer.

- Power supply PCBs can have a range of complex components that require careful 3D design to ensure fit to an enclosure while complying with important safety standards.

Learn more about Altium Designer’s native 3D PCB design features.

- When you’re ready to share your designs with your team members, you use the Altium 365 platform, the only cloud platform that lets you share and collaborate on complex circuit board projects.

Learn more about sharing your PCB project data with Altium 365.

Whether you need to build reliable power electronics or advanced digital systems, use Altium’s complete set of PCB design features and world-class CAD tools. Altium provides the world’s premier electronic product development platform, complete with the industry’s best PCB design tools and cross-disciplinary collaboration features for advanced design teams. Contact an expert at Altium today!