Transform Your PCB Design Processes with PLM Integration

With growing demand and increasing volumes of PCB’s necessary to power the huge number of devices in development today, it falls on PCB designers to be both effective and efficient—their efforts are critical determinants of success. However, if companies have not yet invested in modern technology and teams find themselves dealing with legacy systems, it becomes an uphill battle.

The traditional approach to PCB design often has hurdles, including but not limited to data silos, version control challenges, component obsolescence, poor collaboration, and cumbersome change management, which can lead to increased costs, delayed time-to-market, and a higher risk of product failures.

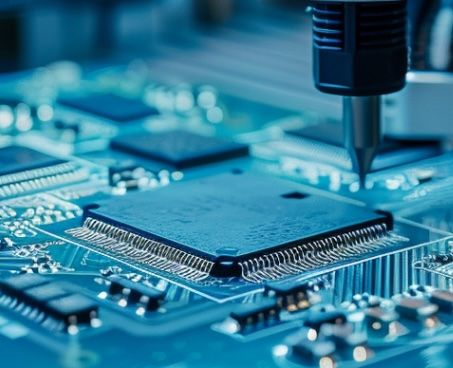

The PCB Design Process

The PCB design process is arguably the most important part of the electronic product development cycle. It is, at least, a strong foundation. It involves a combination of electrical engineering, mechanical design, and manufacturing considerations that, traditionally, have been fraught with challenges, including:

Data silos:

Information related to PCB design is often scattered across various disparate systems and departments. Such siloing of data hampers collaboration and usually leads to inconsistencies in projects; engineers, for example, may have limited access to mission-critical information, affecting the decision-making process and potentially leading to the introduction of errors.

Version control issues:

The management of multiple design iterations can be time-consuming and error-prone without suitable systems in place. If legacy systems lack version control capabilities, keeping track of changes across teams, identifying the current iteration of a design, and preventing overwrites can be a massive pain point—a time-consuming and error-prone one. This can lead to design conflicts, excessive rework, and, in the end, delays in the development process.

Component obsolescence:

With hasty advancements and component lifecycle variations being common in electronics, designers must be on top of component management, which includes keeping up with component availability, lead times, and potential substitutes. Without that, if obsolescence strikes, they will face challenges in sourcing new components, which inevitably result in delays and increased costs.

Inefficient collaboration:

PCB design often involves cross-functional teams, including electrical engineers, mechanical engineers, manufacturing personnel, and quality assurance. If these stakeholders can’t communicate with ease, collaboration takes a hit and the process can be delayed, prone to more errors, and the product quality might lessen.

Time-consuming change management:

Implementing design changes isn’t easy and it takes time. Consequently, coordinating changes across siloed teams, updating documentation, and guaranteeing consistency can be a real challenge, especially without automation for manual processes.

Is Product Lifecycle Management a Comprehensive Solution?

So, these problems necessitate a fresh and integrated approach to the management of product life cycles. Product lifecycle management (PLM) offers exactly that. This software manages the entire lifecycle of a product, from its conceptualization to its eventual retirement, encompassing various aspects, including design, development, manufacturing, distribution, service, and disposal.

For companies that already use PLM, this innovative software platform acts as a company-wide central repository for all product-related information. It acts as a single source of truth to guarantee data consistency and accessibility, which opens the door to collaboration, easier decision-making across silos, and process optimization across the board.

Benefits of PLM Integration in PCB Design

But how exactly does PLM integration into the PCB design process help teams out?

- Collaboration: Courtesy of the improved communication and information sharing among design teams, manufacturing, and other stakeholders.

- Improved data management: Centralized storage and management of design files, components, and documentation help to streamline processes and reduce errors.

- Efficient change management: PLM enables controlled and traceable changes to design data to reduce the risk of disruptions and ensure compliance to relevant regulations.

- Accelerated time-to-market: With the combination of streamlined workflows and reduced changes to design data, faster product development cycles are almost guaranteed, assuming everything else is running as usual.

- Enhanced product quality: Comprehensive data management and collaboration improve the end result of a project.

- Reduced costs: Optimized resource use, reduced rework, and improved product quality lead to cost savings in the long run.

Core Benefits of PLM Integration

PLM integration turbocharges the PCB design process; integration offers companies a suite of capabilities that, when used right, make a massive difference. For example, if a company uses PLM to centralize its data, automate typical manual-entry tasks, and improve collaboration through the facilitation of a single source of truth, it will find itself able to optimize its product development cycles and deliver high-quality products.

Component management

At the foundation of efficient PCB design sits a solid component library; PLM facilitates this centralized repository to hold detailed component information, including specifications, suppliers, costs, and lifecycle stages. This comprehensive view basically facilitates informed component selection, reduces procurement lead times, and helps to mitigate the risk that comes with component obsolescence.

Bill of Materials (BOM) management

Effective BOM management is always super important for accurate manufacturing and assembly. Fortunately, PLM can, through integration with design data, automate up-to-date BOM generation to keep everything consistent and accurate. The software also enables impact analysis of component changes on the overall BOM, which allows for the quick assessment of cost implications and potential design modifications.

Design data management

Efficient management of design data is equally important when maintaining product integrity and facilitating collaboration between teams. PLM provides design release management—to make sure that only approved design data is transferred to manufacturing—and version capabilities that help designers to track changes, revert to previous version of product designs, and manage multiple iterations without hindrance. Comprehensive revision history within the PLM system gives designers an element of transparency and accountability, which enables effective root cause analysis and design improvements.

ECAD/MCAD integration

When it comes to successful product development, the traditional pain point often revolves around solos between electrical and mechanical engineering teams. PLM, in this case, enables integration between ECAD and MCAD tools, which helps to facilitate consistency and collaboration between the two teams’ designs. By providing a shared platform for design data, PLM reduces errors, improves design quality, and accelerates product development cycles.

Supply chain visibility

Understanding the supply chain is one of the most important parts in mitigating risks and ensuring on-time delivery. To keep teams proactive in their supply chain management efforts, PLM provides visibility into component availability. By identifying potential supply chain disruptions early on, organizations can implement contingency plans and reduce the impact on product development. A separate functionality that has proven particularly useful for companies is PLMs support for supply chain risk management, which allows for the assessment of supplier performance and alternative sourcing options in a pinch.

Compliance management

Adherence to industry regulations and standards is also a necessity for product success. PLM helps companies with compliance management by providing a centralized repository specifically for regulatory requirements and certification information, which features continuous compliance status tracking and the generation of necessary documentation. Naturally, such features reduce the risk of delays and product recalls—which are costly affairs best avoided.

Implementing PLM Integration

Successfully integrating PLM into PCB design processes requires careful planning and execution. Below, I outline key steps and best practices for a successful implementation. It is not exhaustive but it does highlight most of what you need to know.

Key Steps for Successful Implementation

- Identify PLM Requirements: Conduct a thorough assessment of the organization's PCB design processes and identify specific PLM functionalities required to address existing challenges. Define clear objectives and desired outcomes for the PLM implementation.

- Select a PLM System: Evaluate available PLM solutions based on the identified requirements, considering factors such as scalability, integration capabilities, user interface, and cost. Select a system that aligns with the organization's overall PLM strategy.

- Data Migration: Transfer relevant data from existing systems (ERP, CAD, etc.) into the PLM platform. Ensure data accuracy and completeness during the migration process.

- Process Mapping: Define and document PCB design processes in detail, identifying integration points with PLM functionalities. This step involves close collaboration between PLM experts and design engineers.

- User Training: Provide comprehensive training to end-users on PLM system functionalities and processes. Ensure adequate training to maximize user adoption and system utilization.

- Continuous Improvement: Establish a feedback loop to gather user input and identify areas for improvement. Monitor PLM system performance and implement necessary enhancements to optimize its effectiveness.

Overcoming Challenges and Best Practices

Implementing PLM can be challenging, but following best practices can mitigate risks and ensure successful adoption.

- Change Management: Effectively communicate the benefits of PLM to all stakeholders and address concerns about process changes.

- Data Quality: Prioritize data cleansing and standardization before migration to ensure data integrity.

- User Adoption: Encourage user participation through training, incentives, and change management initiatives.

- Iterative Approach: Implement PLM in phases, starting with core functionalities and gradually expanding.

- Vendor Partnership: Leverage the expertise of the PLM vendor for implementation guidance and support.

By integrating PLM into PCB design processes, organizations can unlock a wealth of benefits that drive efficiency, innovation, and product success. From enhanced collaboration and improved data management to accelerated time-to-market and reduced costs, PLM empowers businesses to optimize their operations and deliver exceptional products.

The journey to successful PLM implementation requires careful planning, stakeholder engagement, and a commitment to continuous improvement. By following best practices and leveraging the insights from real-world case studies, organizations can maximize the return on their PLM investment.

For the companies that embrace PLM and integrate it into their existing operations, the system will become an increasingly essential tool in their mission to maintain a competitive edge. It will streamline their design processes, reduce errors, and deliver high-quality products that meet the demands of a rapidly changing marketplace, which, I think we can agree, is an absolute game-changer versus legacy methods.