What Every PCB Buyer Should Know About Buying Assemblies

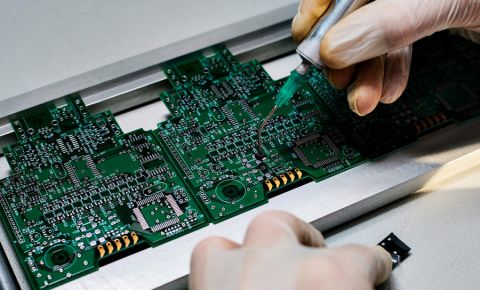

PCBA buyers looking to purchase assemblies should know the potential risks they face with different service levels from an assembly house. A buyer's job is to take the engineering specification and keep it inside, as well as the completed printed circuit boards, and consign these items to a PCB assembly house. Once the assembly process begins, buyers should be aware of all the factors that could increase cost or lead time, as well as watch for these items in a quote from the assembly house.

If these factors aren't understood, buyers may have sticker shock at the price of the assemblies, lead times might be unexpectedly long, or warranties may not be given for certain defects. In the worst case, assemblies need to be heavily reworked or even scrapped simply because a buyer did not understand what they saw in a quote form. Buyers should understand these points as they may need to be specified in a PO or verified in a board house's terms and conditions, and it is the buyer's responsibility to understand what they are purchasing from a PCB assembly company.

Top 5 Surprises When Buying PCB Assemblies

PCB assembly surprises can happen at any point during the assembly process: at the beginning when working up a quote, during assembly, and after boards are received and inspected. Wrong means quotes are too high, lead times are not as expected, or there are multiple pauses throughout the process which delay your delivery date. This includes cases of turnkey assembly, where the only role of the PCB assembler is to source and kit your components.

We have found several common surprises that quickly turn into major headaches:

- Unexpected costs in a quote

- Failing to account for parts attrition

- Inflated parts cost in turnkey builds

- Part-footprint mismatch

- Bare PCB defects that become assembly defects

If you want to avoid these problems, here is some critical information to know.

Turnkey Builds Add a Component Cost Markup

Assemblers essentially offer two service levels for PCB assembly: full turnkey and consigned assembly. In a full turnkey build, the assembler procures the components on your behalf and ensures the delivered parts kits are complete and accurate. In consigned assembly, the customer must order the components from a distributor or kit their own components. The ordered components are then shipped to the PCB assembler.

The most common source of sticker shock in full turnkey builds is due to the markup the PCB assembler applies to the components. The markup can be substantial, and even ordering parts at volume does not do much to offset the markup applied by the assembler. Markups can be as low as 25%, but we have also seen markups exceeding 100%.

Instead, order or kit your own components. The small investment in packaging material and inventory holding will pay off, even on small prototype runs. The franchise component distributor websites make it very easy to upload your BOM and create an order for your build. You can also use free services like the Octopart BOM Tool to scan across distributor inventories and create orders for your components on participating franchise distributor websites.

PCB Assembly Orders Require Parts Overage for Attrition

This is another major reason for cost overruns, especially in consigned assembly. PCB assemblers have overage requirements to account for parts attrition, and it is very common that buyers do not account for the overage requirements. Buyers often miss the overage requirements because they depend on component package size, component mounting (SMT versus through-hole), component package type (leadless versus leaded), and the physical size of the part.

For an example of overage requirements for attrition, take a look at the example below. This example comes from PCB Fab Express, a company I have used many times for PCB assembly.

Image source: PCB Fab Express

Rework Is Not Free

PCB assembly companies will provide rework for an assembly, but rework services come with a price tag. The PCB assembler will only provide free rework in the event you can prove that an assembly defect is the fault of the assembler. They will not provide rework under the following conditions:

- The assembly problem originated in the PCB design data or design outputs

- The assembly error originated as a PCB fabrication defect performed by another company

In the first case, it is solely the responsibility of the PCB designers to ensure the data is correct. If the assemblies are not functional, this may originate in the electrical design, something which assembly rework can't fix.

In the second case, the root cause of the problem and responsibility for it could lie with either the PCB designer or PCB fabricator. In either case, the assembler is not obligated to do rework for free. Fabricated PCBs generally cannot be reworked aside from minor changes on the surface layers. If the designer cannot find a fix, then the boards typically need to be scrapped and the production run may be wasted.

Lead Time Can Provide Price Flexibility

Typical lead time for a PCB assembly order can be approximately 3 weeks for small to moderate size orders. For shorter runs of prototypes, you may be able to get the PCBs sooner, but at a higher price tag.

The reverse is also true: you can often get assemblies for a lower price tag when you are willing to extend your lead time, and the same can apply for PCB fabrication. Lead times are one lever buyers can pull to help offset the cost of expensive components, such as in a turnkey build.

Fabricators Don’t Review Your PCB Footprints

PCB fabrication companies will always put your board through a DFM review to ensure conformance to their processing capabilities. However, PCB buyers and engineering teams should be aware that a PCB fabrication company does not review your PCB for accurate footprints. In fact, a PCB fabrication company does not provide component review services of any kind. You might get lucky with a manufacturer that does both fabrication and assembly, but to date I have not seen these manufacturers provide any kind of footprint review when they receive a design.

Typically what happens is the fabrication house will produce the PCB as designed, and you will not know that a BOM item does not fit the pad arrangement until the PCBs are going through assembly. The assembler will not be able to place the part, and you will be forced to find another solution.

What should a designer or buyer do in this situation? There are a few options:

- Design a simple chip carrier board and produce it overseas for very cheap

- Find a pin- and package-compatible alternative

- Do nothing in assembly and attach the desired component using flying leads

In my experience, I have found that the designers will scrap the boards and rebuild them in a new run.

Obviously, this is the wrong time to find out that your PCB footprint data is incorrect. A comprehensive library review is needed when creating PCB components. For standardized packages, you can also generate the components in your CAD software, such as the IPC-Compliant Footprint Wizard for Altium users.

Always Review and Refine Your Specification

Just like your product’s function has a specification, your PCB assemblies should also have a specification relating to the quality requirements, service level, and expectations for the finished assemblies. It’s common to send the PCBA specification to the assembler when requesting a quote to ensure they can meet your requirements and your service level request.

Whether you need to build reliable power electronics or advanced digital systems, use Altium’s complete set of PCB design features and world-class CAD tools. Altium Develop provides the world’s premier electronic product development platform, complete with the industry’s best PCB design tools and cross-disciplinary collaboration features for advanced design teams. Experience Altium Develop today!

Back

Back