What Is Collaborative Engineering?

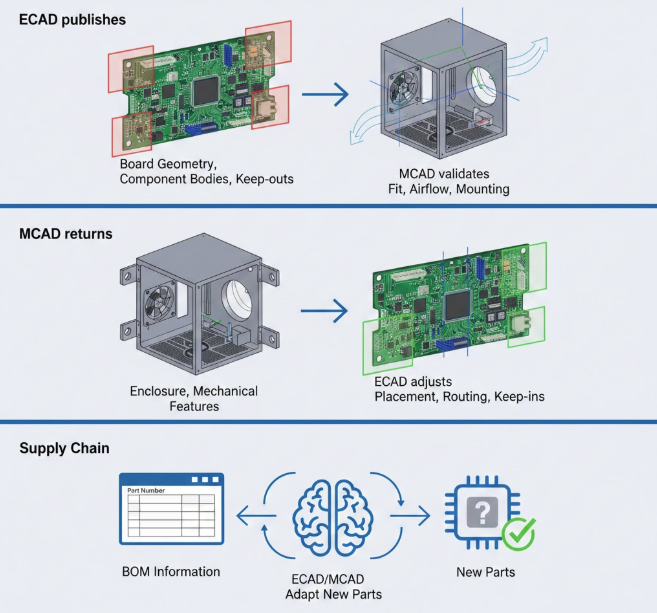

Collaborative engineering is how multi-disciplinary teams design products together in real time. For Altium users, it means ECAD (electrical), MCAD (mechanical), and supply chain stakeholders work in one connected environment, where they are sharing models, BOM intelligence, lifecycle data, and process context. Done well, it shortens cycles, cuts rework and reduces risk from part shortages or mechanical clashes.

Key Takeaways

Collaborative Engineering Defined

Collaborative engineering is the practice of designing products together, not sequentially, by connecting the tools, data, and people across electrical, mechanical, and supply chain domains. Instead of passing files in a relay, teams co-create with live synchronization and shared source of truth.

Core principles:

- Single source of truth for design data (schematics, layouts, 3D models, BOM)

- Bidirectional synchronization between ECAD and MCAD

- Up-to-date supply chain insight (availability, price, lifecycle)

- Shared change context (versioning, design updates, approvals).

Before diving into design, it helps to have a clear set of guardrails. This checklist brings together the essentials for smooth ECAD-MCAD integration, up-to-date supply chain visibility, and clear change coordination. Think of it as your “pre-flight” for collaborative engineering-covering 3D accuracy, BOM intelligence, shared change awareness, and early manufacturability checks. When these boxes are ticked, teams move faster, avoid surprises, and deliver products that launch on time with fewer risks.

Why It Matters to the Three Domains

Successful product design depends on three interconnected disciplines: electrical, mechanical, and supply chain. In particular, ECAD-MCAD collaboration and “digital thread” practices are widely shown to reduce re-spins and time to market; it is only natural to bring supply chain/procurement into the fold. Each brings unique constraints and priorities, and when they work in isolation, delays and redesigns are almost guaranteed. This section explains why collaboration matters for each domain and how early alignment prevents costly surprises.

Electrical (ECAD)

- Designs must fit the enclosure, meet thermal budgets, and respect mechanical limits.

- Component choices should remain available through the product’s lifecycle.

- Early visibility to height, keep-outs, and mounting prevents board spins.

Mechanical (MCAD)

- Enclosure, connector, and fastener elements depend on accurate 3D parts data from ECAD.

- Collisions and tolerance issues are cheaper to fix in digital than in tooling.

- Thermal and structural analyses depend on ECAD fidelity.

Supply Chain

- Up-to-date BOM risk checks prevent last-minute redesigns.

- Lifecycle alerts catch NRND/EOL parts early.

- Cost and lead times drive design trade-offs and launch dates.

Collaboration is a process that has a value stream. The value stream shows how ECAD, MCAD, and supply chain teams exchange data and decisions in real time. By syncing geometry, constraints, and BOM intelligence early, teams reduce risk and accelerate development. Here is how the flow works and why timing is critical.

With supply chain/procurement as part of the collaborative effort, BOM checks happen at the concept stage instead of after a layout being completed. Then, the ECAD-MCAD sync can run continuously so that DFM/DFA feedback returns early to the designers.

A Day in the Life: Cross-Domain Collaboration

What does real-time collaboration look like in practice? A common scenario is described below, where a single design change shows how ECAD, MCAD, and supply chain teams resolve issues together-without email chains or late-stage surprises.

- ECAD moves a board-to-wire connector by 1.5 mm for routing clearance.

- MCAD sees the change instantly; a clash marker appears against the enclosure wall.

- MCAD adjusts the enclosure openings → thermal team validates airflow impact.

- Supply chain warns the board-to-wire connector supply is too to support an upcoming run; proposes an alternative that meets reliability requirement.

- ECAD swaps the component; MCAD confirms mechanical fit is still appropriate.

The result is a faster, more coordinated change cycle, and no surprises in a prototype build. Modern collaborative design platforms like Altium Develop bring these domains together.

Measuring Success

How do you know if your company’s or team’s collaborative engineering is working? Any process, product, or project should have defined metrics against which we can judge success.

The answer lies in tracking the right signals that are relevant to PCB design and product development cycles. Leading indicators show early progress, such as like fewer board spins and shorter cycle times. Lagging indicators confirm the long-term impact of collaborative engineering practices, such as fewer field failures. The table below shows some leading and lagging metrics that indicate success.

|

Leading |

Lagging |

|

Fewer board spins and enclosure reworks. |

Fewer field returns due to fit/thermal issues. |

|

Shorter cycle time from concept to release. |

Reduced expedited shipping or last-minute component premiums. |

|

Lower BOM risk scores at pre-release. |

Improved on-time launch performance across programs. |

|

Higher first-pass yield in prototypes. |

Conclusion

Co-design is not just file sharing, but a continuous exchange of geometry, constraints, and proposals. Collaborative engineering aligns electrical, mechanical, and supply chain work around one truth. For Altium users, that means ECAD-MCAD collaboration, up-to-date BOM intelligence, and shared change awareness. The payoff is tangible: fewer surprises, resilient supply chains, and products that launch on time with quality intact.

Whether you need to build reliable power electronics or advanced digital systems, Altium Develop unites every discipline into one collaborative force. Free from silos. Free from limits. It’s where engineers, designers, and innovators work as one to co-create without constraints. Experience Altium Develop today!

Frequently Asked Questions

What is collaborative engineering in electronics design?

Collaborative engineering is a real-time, cross-disciplinary approach where ECAD, MCAD, and supply chain teams work from a shared set of design data instead of passing files back and forth. It enables teams to co-design, review changes instantly, and resolve issues early.

How is collaborative engineering different from traditional ECAD–MCAD handoffs?

Traditional workflows rely on sequential file exchanges, which often introduce delays and version conflicts. Collaborative engineering uses bidirectional synchronization and a single source of truth, so electrical, mechanical, and supply chain updates stay aligned as changes happen.

Why should supply chain teams be involved during early design?

Early supply chain visibility helps catch risks like NRND/EOL parts, long lead times, or cost spikes before layouts are finalized. This prevents late-stage redesigns and supports better trade-offs between performance, cost, and availability.

What problems does collaborative engineering help prevent?

It reduces board spins, mechanical clashes, BOM-related rework, and last-minute component substitutions by surfacing fit, thermal, and sourcing issues earlier in the design cycle.

How can teams measure whether collaborative engineering is working?

Common indicators include fewer prototype reworks, shorter concept-to-release cycles, lower BOM risk before release, improved first-pass yield, and more consistent on-time product launches.