Seamless Wearable Technology of the Future

Most digital interactions still demand attention – buzzing alerts, swipes, and screen time that disrupt the moment. Next-gen wearables are beginning to change that. The best of today’s smart wearable tech anticipates user intent, reduces friction, and seamlessly integrates into the rhythms of daily life.

Imagine you’re walking the dogs. A message arrives, but instead of a buzz or a screen flash, your smart glasses quietly speak in your ear: “New message from Sarah…Dinner at six?” You say, “Reply, sure, let’s meet at six.” No hands, no phone, no break in stride. That’s seamless wearable technology.

Or consider a discreet biometric health patch that tracks vitals and shares a patient’s real-time data to a care team, with no app for the user to open, learn, or adjust. It just works quietly, continuously, and comfortably in the background.

Across wearable technology categories, seamless experiences share a few defining traits:

- User Interaction fades into the background. Devices only require taps, swipes, and codes when absolutely necessary and stay silent the rest of the time.

- Design aligns with daily habits. These products work with familiar habits and routines. If you already wear glasses, why not a pair that plays music, takes photos, makes calls, and reads messages? If you wear a ring, why not have it track your sleep or other biometric data?

- Comfort and style are essential. A smart ring should look like jewelry. A patch should feel like nothing. Wearable tech glasses should be stylish and comfortable all day. The fashion, jewelry, and tech industries will be converging.

- Context is understood and anticipated. Seamless wearables learn when to act and when to stay silent. A smart ring vibrates when a medication is missed. Glasses respond when spoken to. The best devices support your intent without interrupting your flow.

Each of these traits contributes directly to product adoption by making wearable devices feel natural, intuitive, and delightful to wear daily. As devices become more embedded in daily routines, seamless wearable experiences will define the category.

Wearable Technology: Beyond Effortless to Truly Empowering

Beyond everyday convenience, wearable devices are beginning to unlock life-changing experiences. Take Meta’s smart glasses. Early adopters included people with impaired vision who struggle with everyday tasks. For $350, they gained something remarkable: the ability to ask, “Hey Meta, what am I looking at?” The glasses snap a photo, analyze the scene with AI-powered sensors, and respond in plain language.

Need help reading a menu in low light? Ask, and the wearable interface reads it quietly into your ear. No special settings, no awkward gestures. Just a natural voice, heard only by you. For these users, the experience delivers independence.

We are at a turning point. Next-gen wearable technology are becoming front-line interfaces for communication, navigation, health, and much more. And they are doing it in ways that feel natural and fluid.

Wearable Tech Is a Fast-Growing Sector

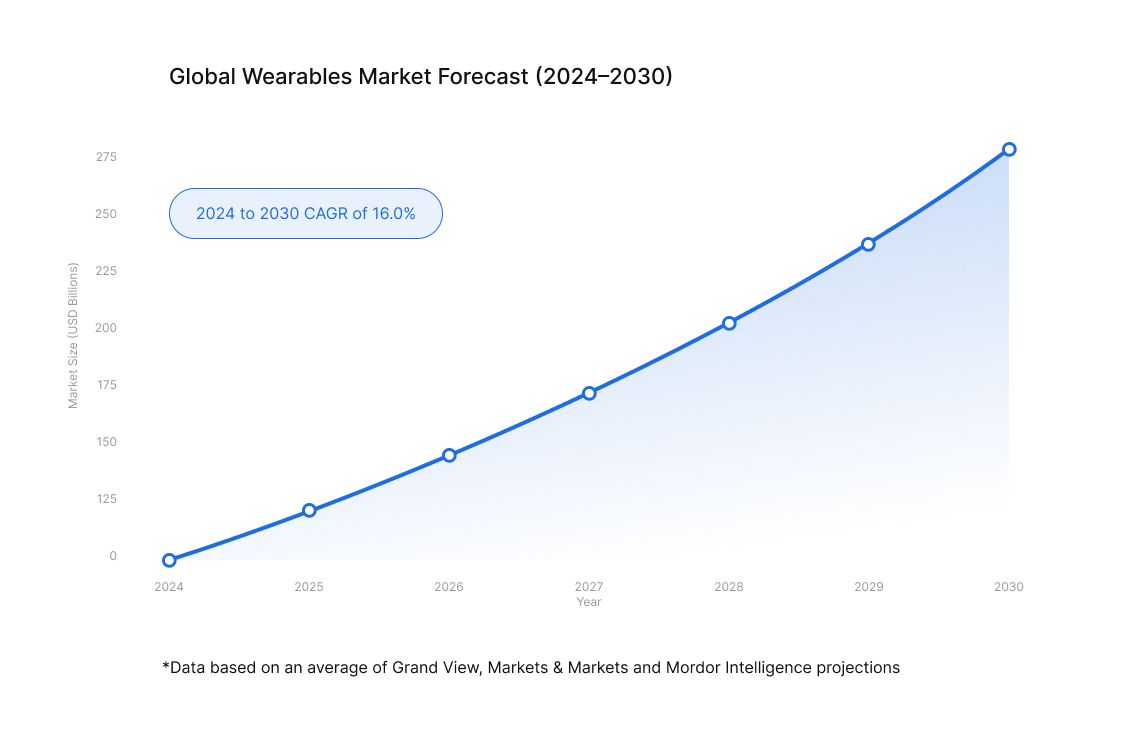

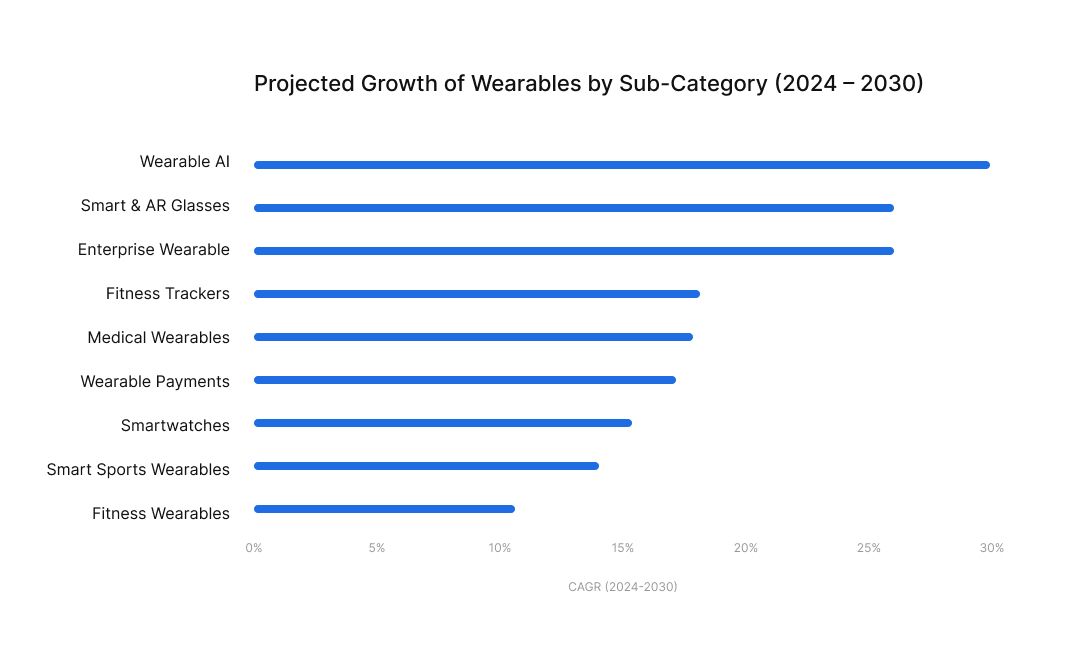

From 2024 to 2030, analysts project a compound annual growth rate (CAGR) of approximately 16%, with the market expected to surpass $275 billion by the end of the decade.

Leading subsegments, including wearable AI, smart/AR glasses, and enterprise wearables, are forecasted to grow even faster, all with a CAGR of over 25%.

Building Seamless Tech From the Inside Out

Creating seamless wearable technology begins with the physical layer. Smart wearables must move with the body, conform to its contours, and withstand friction, moisture, and daily wear and tear. This requires a new design approach that fuses electronics with flexible materials and mechanical form.

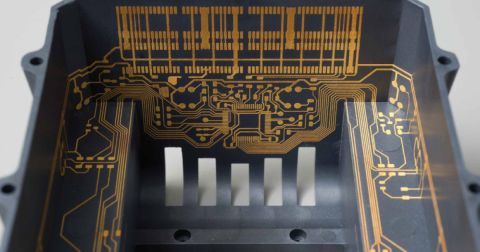

To break free from rigid constraints, engineers are turning to structural electronics. Techniques like in-mold structural electronics (IMSE), printed electronics and 3D-MID (Three-Dimensional Mechatronic Integrated Devices) embed circuits directly into the form of the product. Instead of forcing a flat PCB to fit a curved surface, the board itself follows the natural shape of the body.

For example, in a recent OnTrack Podcast episode on structural electronics, Altium product manager Jack Henriques explained how Altium’s 3D PCB tools enable traces to follow curved surfaces without losing signal integrity. “You can route traces over complex curved surfaces, and the software maintains consistent trace width, helping avoid signal degradation, even in ergonomic shapes,” Henriques noted.

By supporting nontraditional wearable design and embedded electronics, Altium solutions open the door to a new generation of seamless, body-aware wearables.

This Is What Seamless Wearable Tech Looks Like

Here are a few standout products that are redefining what seamless wearable tech looks and feels like in the real world.

- Mudra Band for Apple Watch: This neural wristband transforms finger movements into commands using bioelectric signals. Users can accept calls, scroll, or launch apps with subtle gestures. It brings touchless control to the Apple Watch ecosystem, making wearable tech feel more like an extension of the body.

- Meta Ray-Ban Smart Glasses (2nd Gen): These market-leading smart glasses integrate Meta AI for intuitive, hands-free interaction, enabling wearers to send messages, make calls, and receive real-time descriptions of their surroundings. A 12 MP ultra-wide-angle camera supports POV photo and video capture, while open-ear spatial audio delivers music and calls without blocking ambient sound. With support for live streaming, discreet voice responses, and classic Ray-Ban styling, the glasses offer style, practicality, and surprising affordability. Since launching in late 2023, they have sold more than two million units.

- Voormi Mij Smart T-Shirt: This next-gen wearable embeds micro-thermal sensors directly into knitted Merino fabric, creating a continuous biometric grid that monitors body temperature, humidity, and thermal load. Data is transmitted via Bluetooth and NFC to a companion app, where users can see real-time heat index and micro-climate insights. Despite its advanced tech, the shirt wears like a breathable and washable high-performance tee. Field professionals and endurance athletes are already adopting Mij shirts to track thermal stress and optimize hydration and rest.

- identifyHer Peri Patch: The women’s health space is one area where innovation is long overdue, and new wearables are helping to fill this void. Unveiled at CES 2025, the identifyHer Peri Patch is a discreet adhesive wearable that continuously monitors symptoms such as hot flashes, sleep disruption, and heart rate variability. The patch delivers clinically relevant data to a companion app for users and care providers. Its minimalist form factor and passive operation make it well-suited for daily life, offering meaningful support without requiring active engagement.

- XREAL One Pro: XREAL’s flagship AR glasses combine micro-OLED optics, spatial audio, and a frameless 90-gram design to create an immersive experience that feels more like stylish entertainment eyewear than a device. Electrochromic dimming and a 57° field of view deliver an impressive VR-like experience, allowing people to stream media or interact with content discreetly, even in transit.

- Circular Ring 2: This titanium smart ring offers clinical-grade health tracking, including ECG and anomaly detection, in a compact and stylish form. With no distracting notifications and up to eight days of battery life, it prioritizes discretion and wearability without sacrificing performance.

- Bee Wristband: Amazon recently acquired Bee, making a bold move into the wearables space. The sleek wristband transforms everyday moments into meaningful insights with a personal AI assistant that quietly captures conversations and tracks patterns, then surfaces timely reminders and summaries when needed. With dual microphones and advanced noise filtering, Bee delivers crystal-clear audio processing across 40 languages.

Designing the Future of Seamless Wearable Technology

The most exciting wearable technology on the market today resembles stylish clothing, jewelry, or eyewear that just happens to be more functional. This integration is possible because the user experience is so well-designed, the technology fades into the background. Achieving this level of seamless design calls for coordination across disciplines, from materials and mechanics to electronics and interface design.

Behind these breakthrough products are cross-functional teams solving tightly coupled engineering and aesthetic challenges. Altium solutions provide a collaborative design platform where engineers, designers, and RF/mechanical specialists collaborate in real time, aligning decisions across disciplines and accelerating the path to market-ready smart wearables.

Back

Back