How Structural Electronics Enables 3D, Flexible, and Wearable Integration

I spent a week redesigning circuits because a mechanical engineer couldn't change an enclosure. The analog signals had to wrap around the entire board, doubling trace length, all because cables needed to exit specific sides of the box.

That was traditional electronics. Structure first, circuits second.

Structural electronics integration flips everything. The circuit becomes the structure. The structure becomes the circuit.

This shift sets the foundation for new possibilities in 3D flexible electronics and wearable structural electronics that unify electrical function with physical form.

Structural Electronics: What Becomes Possible

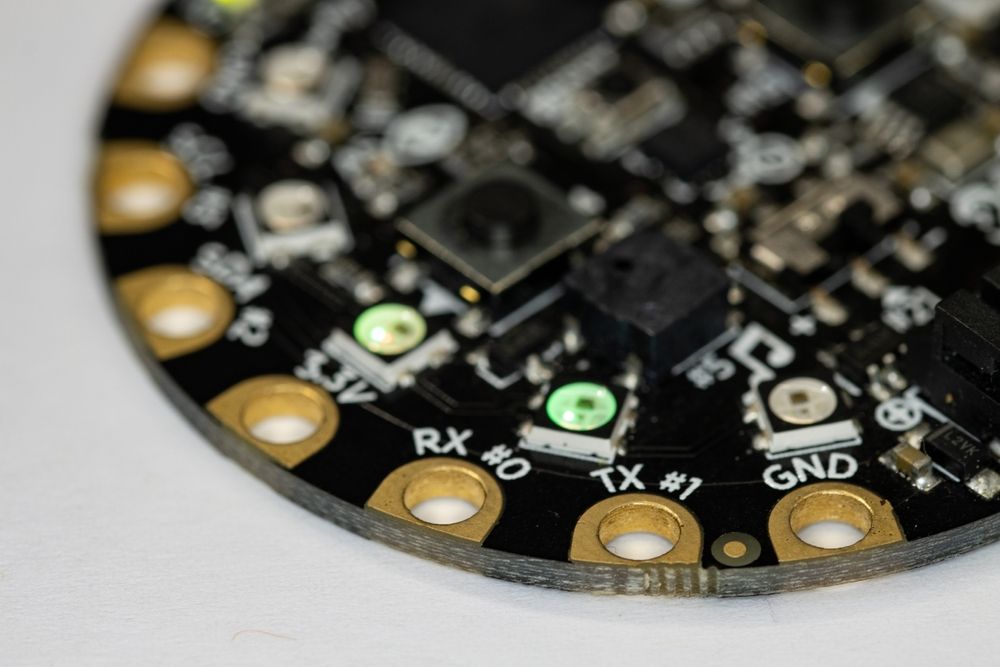

Imagine a smartwatch where the band itself monitors your pulse, not through attached sensors, but through embedded electronics in flexible materials like conductive fibers woven directly into the material to detect blood flow patterns.

The display bezel contains touch sensors, and the crown integrates pressure detection. Every surface becomes functional while maintaining the mechanical properties you expect.

This is already happening. Recent breakthroughs in stretchable electronic circuits and liquid metal interconnects enable exceptional conductivity with high flexibility, creating electronics that bend, twist, and stretch like fabric, clearly ideal for wearable structural electronics.

Structural Electronics: Beyond Wearables

Smart clothing represents just the entry point. Research in digital embroidery has created garments that monitor health during daily activities while maintaining durability and breathability.

But the real transformation happens in applications where traditional electronics fail.

Imagine aircraft wings embedded with stress sensors throughout the structure—not mounted on the structure, but structurally integrated electronics that form part of the composite material. Every rivet, every panel becomes a data collection point without adding weight or complexity.

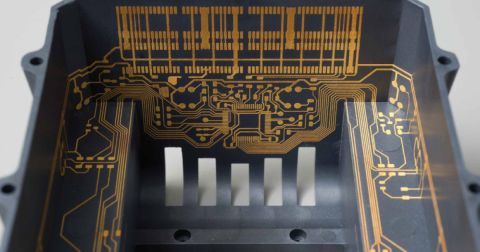

In the automotive industry, dashboards evolve into single, integrated units. The plastic housing contains all the circuits for displays, controls, and sensors—eliminating the need for wire harnesses in smart surfaces and traditional PCB assemblies. No separate PCBs. No discrete component mounting. Just seamless electronic integration in molded structures.

The Structural Electronics Manufacturing Revolution

Traditional electronics require multiple steps:

-

Design the PCB.

-

Manufacture the board.

-

Assemble components.

-

Design the enclosure.

-

Integrate everything.

Structural electronics collapse this into a structural electronics manufacturing process. MIT’s 3D-printed electronics can be manufactured anywhere, breaking traditional supply chain models entirely.

The implications for mechanical engineers are profound. You’re no longer designing containers for electronics—you’re designing functional materials with embedded circuits. Weight disappears as a constraint. When circuits integrate into existing structures, electronic functionality adds virtually no mass to the system.

But mixing these two worlds isn’t always easy. Even though there are clear benefits, joining these areas brings new challenges and opportunities for both mechanical and electrical engineers working in 3D flexible electronics and wearable structural electronics.

What Mechanical Engineers Must Now Consider

Here's what most mechanical engineers don’t realize about electrical constraints. When you force longer signal paths due to mechanical decisions, you're not just adding copper traces. You're adding resistance, inductance, and capacitance to the signal path. Every millimeter matters electrically.

Signal integrity becomes your responsibility too. Electrical signals don’t flow like water through pipes. At modern frequencies, traces become transmission lines with characteristic impedance. That impedance depends on trace width, thickness, and distance to ground planes. Change the mechanical stackup, and you change the electrical performance directly—especially in structural electronics integration scenarios.

High-speed digital signals are especially sensitive. A 1 GHz clock signal has wavelengths measured in centimeters. Your mechanical decisions directly impact signal timing.

EMI and Power Distribution Challenges for Structural Electronics

Digital switching generates electromagnetic noise. Every signal transition leads to current spikes that force voltage fluctuations through the ground system.

Traditional PCBs resolve this by including dedicated power and ground planes that maintain clean and stable power distribution. In structural electronics, however, power delivery must embed directly into the mechanical structure. In this architecture, power traces run through flexible materials, and their resistance changes as the structure bends or deforms.

Thus, components in different parts of a structure may see varying supply voltages under mechanical stress. Electromagnetic compatibility becomes a system‑level design concern. The mechanical structure must serve as shielding while preserving flexibility, mechanical integrity, and power integrity.

Loop areas are pivotal, shaping both electromagnetic emissions and susceptibility to interference. In flexible structures, these loop areas shift dynamically as the system moves, causing continuously changing electromagnetic behavior.

Smart Infrastructure Takes Shape with Structural Electronics Integration

Building materials embedded with sensors create structures that monitor their own health. Concrete beams can detect stress and fatigue, while bridge cables report tension and vibration. The construction industry transforms when structural elements become intelligent, enabling real-time insight into performance and structural integrity.

Maintenance shifts from scheduled intervals to predictive analytics based on continuous data streams. Instead of replacing components on a fixed timetable, engineers act precisely when needed—improving safety, longevity, and cost efficiency.

Medical devices benefit enormously from similar integration principles. Prosthetics adopt embedded sensors and actuators to boost responsiveness. Surgical implants monitor healing progress and detect complications early. Even bandages are evolving, tracking wound recovery and automatically adjusting medication delivery.

Each application demands new thinking about form and function. The mechanical properties of materials must not only serve their intended structural or medical roles but also support embedded electronic functionality. In doing so, durability, flexibility, and intelligence must merge into a single cohesive design.

Aerospace Demonstrates the Power of Structural Electronics Integration

High-reliability applications showcase structural electronics’ full potential. One such domain is air travel and space, where rigorous performance standards accelerate maturity faster than consumer markets alone.

With new electric aircraft quickly being developed thanks to new and rapid increases in the energy density of batteries, we are able to help further eliminate weight while maintaining safety through the structural and thermal optimization of electrical enclosures, says ASR Engineering in their article Aerospace Electronics: What Role Does it Play? - ITChronicles.

Although weight reduction often draws attention, the real leap lies in capability. Since these systems integrate circuitry directly into structural components, they offer strength and electronic functionality perfectly suited for tasks like in‑flight health monitoring, lightning strike detection, and performance sensing in real time. Traditional systems still perform many of these tasks, but integrated electronics point toward a more efficient, intelligent future.

Applications in military and space demand extreme reliability, so structural electronics will likely advance faster in those sectors than if limited to consumer products. These premium domains also subsidize research that eventually drives innovation in mainstream devices.

Material Properties You Need to Understand

With structural electronics integrated into new products, component selection evolves drastically. Traditional electronic components assume rigid mounting on flat surfaces. But structural electronics demand parts that endure mechanical stress while preserving electrical performance. This added complexity forces electrical engineers to widen their parametric searches on component supplier sites.

That means package types matter more than ever. For example, ball grid array packages that behave well on rigid PCBs might develop solder‑joint cracks under flexural stress — an issue legacy PCB design rarely encounters. Even neutral factors like component orientation affect long-term reliability based on stress distribution, not just assembly cost or routing simplicity.

Passive components also change behavior under mechanical stress. Ceramic capacitors may exhibit piezoelectric effects, altering capacitance when stressed. Designers must consider broader capacitance ranges than manufacturers typically specify.

We might soon see capacitor variants with mechanical‑stress tolerances built into their specs, accompanied by mechanical stress curves on datasheets.

Temperature effects further complicate behavior. Components’ temperature coefficients affect resistance and performance. In structural electronics, thermal expansion ceases being only a mechanical issue: conductor spacing shifts under heat, turning it into an electrical concern as well.

Structural Electronics: The Tool Evolution

So how do we address these emerging challenges? Traditional design tools have long assumed a clear separation between the mechanical and electrical domains. While that distinction still holds in many cases, structural electronics integration increasingly blurs the boundary between the two—more than many existing tools and processes can comfortably accommodate.

Traditionally, Mechanical CAD (MCAD) software focuses on physical design, while ECAD / EDA tools handle circuitry and layout. In many organizations, simulation and design environments remained siloed across these domains. But today, engineers more often use multidisciplinary models that combine mechanical, electrical, and control system attributes—especially in aerospace and automotive applications. These physics-based models, such as “virtual commissioning,” test mechanical, electrical, and control behaviors simultaneously in a unified environment.

Although both electrical and mechanical engineers must deepen their understanding of each other’s domain, it would be far better to integrate these trade-offs directly into design tools. We already embed material and physics data into ECAD field solvers for impedance control; structural electronics demand even tighter ECAD–MCAD convergence so electrical engineers do less manual translation.

With structural electronics gaining traction, future design workflows will require integrated solutions. In time, mechanical decisions might instantly reflect electrical consequences, just as electrical choices affect structural performance.

It’s no surprise that multi-physics simulation has become a standard practice under realistic environmental conditions. Electromagnetic solvers now couple with mechanical stress analysis to reveal the full system picture. Thermal models must account for both power dissipation and structural heat transfer. Structural electronics will benefit strongly from such mechanical-electrical co-design capabilities. With all these facets in play, one truth is evident:

Design verification demands new methodologies and tool paradigms. You can no longer optimize electrical performance in isolation—you must understand mechanical constraints at the same time.

What Mechanical Engineers Need Now

For mechanical engineers, the fundamentals still hold: stress analysis, material properties, and thermal management remain essential. But in the realm of structural electronics, the design context expands dramatically.

Material selection now must include electrical properties. Mechanical analysis must consider dielectric constants, conductivity, and electromagnetic shielding effectiveness—these factors gain equal importance alongside mechanical strength and temperature resistance. In Kraig Mitnzer’s writings, he argued that mechanical properties should take priority, so long as electrical performance remains intact.

Structural electronics raise the stakes: successful integration of electronics and mechanics becomes interdependent, leading to a shift in how priority decisions get made in mechanical design. Mechanical engineers must understand how dielectric constants influence signal propagation, how thermal expansion alters electrical behavior, and how mechanical stress changes component characteristics.

But where does one begin? The quickest path is mastering mechanical electrical co-design fundamentals. Learn why trace geometry affects high-speed signal integrity, how power layout impacts circuit behavior, and how spacing influences electromagnetic fields.

Designing the Future: When Structures Think

We're moving beyond electronics as isolated components added to mechanical systems. While mechanical-electrical integration will still define many traditional designs, the future lies in products and materials that inherently combine both structural and electronic functionality.

This shift introduces new engineering challenges, but it also opens doors for engineers who master both disciplines. Entirely new product categories emerge. Existing systems gain capabilities that were impossible under the old separation of structure and circuit.

Adopting this approach demands new tools, processes, and thinking. The way we define the relationship between form and function changes. But the payoff justifies the complexity—structural electronics create responsive systems that adapt to real-time conditions and user behavior.

The engineers who embrace this synthesis will shape the future of intelligent structural design, driving a new era of smart materials and multifunctional products.

Explore how Altium supports printed electronics and enables the integration of electrical circuits with three-dimensional mechanical parts.