High-Power Output Power Supply Design

A designer faces far more challenges when dealing with devices requiring a power supply with high power output. For a start, they can’t opt for an off-the-shelf IC package for their converter/regulator requirements. In addition, the combination of high voltage and high current requires careful component selections and design decisions. Also, no power supply circuit is perfectly efficient, so the designer must constantly manage the heat produced by losses within the circuit components. Nevertheless, the following tips provide a good starting point for considering when designing a device that includes a high power output power supply.

Trace Length

The first tip may be obvious but can often be forgotten. Keep traces that carry high currents short, as short as possible. This approach keeps resistive losses down and makes it easier to design the traces as wide as board space allows using polygon pours. In addition, it reduces the risk of cracks forming in the trace by physical flexing due to thermal expansion cycling effects.

Trace Area

Short and wide traces are good, but for very high currents, they may still be inadequate. A common technique uses a solid fill in an internal layer that high current devices connect to using vias. Increasing the copper thickness is usually the next step for increasing current carrying capacity by reducing the current density. The main disadvantages of thicker copper layers are increased manufacturing costs and lead times.

Another solution for reducing current density is not applying a solder mask to the traces carrying high currents and allowing the solder to create a layer on top of the copper trace. This process is relatively simple, but it has the disadvantage that the two layers of dissimilar metals will be prone to cracking due to thermal expansion effects across the board. Also, this only works for traces on the top and bottom of the board.

A more straightforward method is to create an external conductor link across the board using a length of wire or a copper busbar. PCB bus bars eliminate the need for thicker copper layers by providing a high current path across the PCB. These are available as laser-cut bespoke shapes to integrate with the board design. In addition, busbars are available that can be bolted or wave-soldered into place.

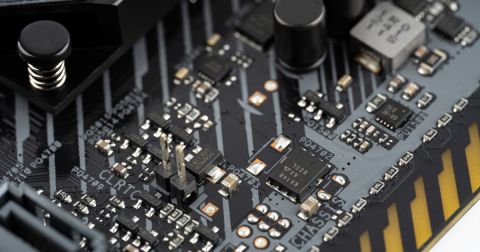

Component Mounting

The point where a component is mounted to the board will create areas where the high currents flowing through the board need to feed into the component through a single conducting pin. This issue can be particularly seen with high current FETS. Parts are available with a 90A rating that may appear perfect for a high-power application. However, when mounted to a PCB, the conducting pin area is too small to handle this maximum rated current. The component selection must consider the current that can flow into the device and the current that the component itself is rated to handle. With high current applications, it’s often the board design and constriction that limits the current.

A solution, in this case, is to parallel multiple smaller components, so the current flow from the board through the component pins is divided down to below the maximum value. This solution will require more board space and potentially increase costs, but the lower current density in the board will come with a larger heat dissipation area.

Thermal Management

No power supply circuit is perfectly efficient, so the designer is always aware of managing the heat produced by losses within the circuit components. High power output requirements exacerbate these issues and introduce the need to handle the heat from PCB track losses due to the large current flows.

Electronic components that handle high currents will produce high levels of thermal energy that will need to be managed. This heating places constraints on positioning such components on the board that must be balanced by the overriding need for short trace lengths. Traditional advice is to distribute such components across the board to dissipate the thermal energy, but this requires a trade-off with trace length. Having all such parts close together will generate a localized hot spot that will need careful thermal management to conduct and radiate the energy away using in a controlled manner. Hot spots left unchecked can cause warping of the board, cracking, and even delamination of the board in extreme circumstances.

A common feature with controlled power supplies, particularly the switch-mode variants, is the feedback circuits that control the voltage output are typically sensitive to changes in temperature. It is therefore essential that thermal management ensures that heat is dissipated away from those components that implement the control functions. Furthermore, this must be in such a manner that this area of the board experiences relatively stable temperatures over the device’s operating range using thermal isolation design techniques such as board cutouts to protect components from high board temperatures.

Board Design

When designing the board layout, thermal management should be the second priority after current density. Using traces to conduct thermal energy from hot components can be enhanced with the use of thermal vias to connect multiple layers and increase the thermal conducting capacity of the board. In addition, polygon pours around components can create areas that provide more efficient thermal conductance if necessary. Via stitching techniques can also help direct heat flow away from hot spots and thermally sensitive parts to boards areas capable of absorbing or radiating the thermal energy.

Summary

When designing high-power PCB layouts, the challenge is to co-manage high current flows and thermal management issues together, when they can often throw up contradictory design requirements. The test of a good designer is solving these problems without resorting to expensive solutions.

The thermal implications of high currents and temperature in traces can be wide-ranging for the complete circuit board. Therefore, calculating the current density in the PCB will ensure that the design will work effectively in the planned operating environment. For more information, refer to my article on quick and dirty copper current density simulations.

I’ve previously written an article on designing a new switching power supply with a 5.0V and 6.0A output requirement using a high current buck converter design which contains helpful advice for designers.

Have more questions? Call an expert at Altium and discover how we can help you with your next PCB design. You can download a free trial of Altium Designer here.