How to Design a Coaxial Probe Feed for a Patch Antenna

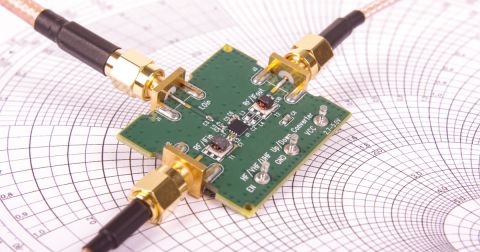

Implementation of a patch antenna in a PCB requires connection to another component or external module. This connection is very often placed as a microstrip line, possibly with a quarter wavelength matching line, such as in patch antenna arrays for advanced wireless systems. There is another method involving an SMA or other coax connector, but not on the same layer as the antenna.

Coaxial-fed patch antennas involve the use of a patch antenna on one side of the PCB, while the feedline is routed on the back side of the PCB. The connection between the two layers is implemented using a via. This article will show the main design equations for implementing this type of feedline method, as well as a simple example of this type of module.

Coaxial Feed to a Patch Antenna

The coaxial feed to a patch antenna involves placement of the patch antenna and its feedline element on two different layers. Normally we would put the patch on the top layer, and the feedline connection on the bottom layer. The feedline would then connect to the PCB through a vertical SMD coaxial connector (e.g., a vertical SMA connector such as 73251-1350 from Molex), and an internal via would route the injected signal to the patch antenna.

As we can see above, the coordinate where the patch antenna attaches to the via is not located at the center of the antenna. This is intentional because the antenna impedance varies across the surface of the patch antenna. Therefore, we want to connect the probe at a location where the input impedance into the antenna matches the coax cable/connector impedance. To do this, we first need the antenna impedance at the edge of the antenna, and we can use this to determine the feed location.

Coaxial Feed Design Equations

The standard set of design equations for end-fed patch antennas are used to size the patch used in this type of design. After this is completed, the coax feed location can be determined. To find the design equations for the patch dimensions and edge-feed patch impedance can be found in another article (linked below). You can also use our patch antenna calculator:

Once the patch impedance and length have been found, these need to be used to determine the inset feedline location. Normally, we are using a coaxial cable and a connector with matched impedance (normally to 50 Ohms). This is our target impedance to which we would like to match the patch antenna. At some location along the x-direction (see below), there will be a particular location where the antenna’s impedance will be 50 Ohms. This is the location where the feedline will be connected.

The location of the x-coordinate is found with the equation shown below.

In summary, the design process for the coaxial probe placement is simple:

- Select an operating frequency and stackup

- Use the frequency and layer thickness/Dk value to determine the antenna size

- Calculate the edge input impedance for the antenna

- Use the above equation to calculate the x-coordinate for the probe location

How to Design the Stackup

The first image above implies that the only allowed stackup for this type of connection is a 2-layer board, where the antenna is on the top layer and the antenna’s ground plane is on the bottom layer. While a 2-layer, standard 62 mil thick board can certainly be used, this is not a strict requirement. The benefit in using more than two layers comes from the ability to use digital components and high speed signals on the back side of the PCB, while the antenna is isolated on the opposite side of the PCB.

Take a look at the stackup example below. In this stackup, we could place GND on L2 and L3 as this would allow placement and routing of signals on L4. When the antenna is placed on L1, the thickness below L1 (4 mils in this case) would be the value used for the substrate thickness in the patch antenna design equations. More internal layers could also be used if desired.

Making the Connection in CAD Tools

The example below uses the 4-layer stackup shown above, with an SMA connector on L4 and the antenna on L1; L2 and L3 are ground. To make the connection to the patch antenna, a via should be placed directly from the center of the SMA connector, and it should be filled + capped so that the SMA can be soldered onto the via pad.

This type of via will be acceptable up to about 5 GHz. Beyond that level, the via structure will need to be optimized to a 50 Ohm target impedance with stitching vias, which might affect the signal propagation and modes in the interior of the patch antenna. This is because the via impedance diverges, as I’ve discussed in this article.

In an upcoming article and video, I’ll show an example module that uses a patch antenna for broadcasting at high frequency, and it will include a set of circuits on the back layer that use the feedline through the back side of the PCB. I’ll also show how to set a via style through the back layer that can handle much higher frequencies in the upcoming video.

Anytime you need to place antennas and design feedline methods, you can use the complete set of CAD utilities in Altium Designer®. When you’ve finished your design, and you want to release files to your manufacturer, the Altium 365™ platform makes it easy to collaborate and share your projects.

We have only scratched the surface of what’s possible with Altium Designer on Altium 365. Start your free trial of Altium Designer + Altium 365 today.