An Overview of Power Supply Design

Power supplies are an essential element for all electronics equipment, irrespective of whether they use batteries, mains power, or any other power source to energize their electronic circuitry. It is therefore crucially important to get the design of the power supply correct. Any errors and the power supply may deliver the wrong voltage or be unable to provide the required current. It may generate too much noise that affects its own circuits of nearby equipment. It may even fail in a manner that can cause a hazardous situation, be that an electric shock or cause an uncontained fire. The list of potential problems from incorrect design goes on.

Power Supply Design Considerations

For power supplies connected to AC mains supplies or other noisy energy sources, input filtering is essential to minimize the effects of transients and noise at the input affecting the power supply output. The filtering required will depend on the AC input's nature, other devices connected to that supply, and the circuitry's sensitivity connected to the output. For example, AC supplies in industrial environments where high current switching circuitry is present will typically have significant voltage spikes present that could damage an unprotected power supply.

For AC-connected power supplies based on the traditional transformer and rectifier technology, over-voltage protection on the power supply output should be considered to prevent any fault in the rectification from causing consequential damage to connected circuitry.

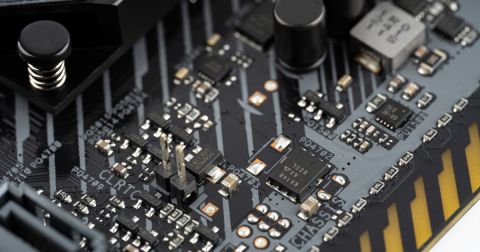

PCB thermal management is an important consideration. Power supplies can generate high localized temperatures that need to be dissipated efficiently. This issue is particularly relevant for linear regulators with a considerably higher power loss than an equivalent switch-mode power supply circuit. The PCB area around the power supply can potentially be prone to thermal distortion due to temperature changes, causing physical movement and affecting components mounting in that area. Some parts such as capacitors and encapsulated integrated circuits can be sensitive to such motion, resulting in cracking or materials and wires.

For switch mode power supplies, calculating the optimum operating frequency requires a trade-off between performance, efficiency, cost, and physical size. Typically the lower the frequency, the better the efficiency, and the higher the frequency, the better the cost and size. However, components required for filtering tend to dominate these factors and so getting the filter design right should be before moving onto the switching circuit design.

Power Supply Design Guidelines

Designing complex power supplies requires the use of a simulation tool such as SPICE. Manual recalculations for different design options and component selection will take too long and carry too significant a risk of errors being made. Integrated Circuit manufacturers offer design tools for simulation and component calculation purposes that can give designers a head start.

PCB layout can significantly influence output noise levels for a power supply, both as line ripple and emitted electromagnetic radiation. Time spent optimizing the layout can save time resolving noise issues and add additional filtering components.

When designing a switch-mode power supply, the input filter must be correctly designed to ensure the filter characteristics combined with the input impedance of the power supply cannot result in resonant oscillation issues under certain circumstances. This problem will be influenced by power supply loading, highlighting the benefits of using simulation tools to model complex operating conditions.

When modeling designs, don't forget to check the damping of inductive components. It is vital to ensure that a step change to current flow cannot generate voltages that exceed the maximum rated values of the power supply components or damage circuitry connected downstream of the power supply output. Such transient effects are most commonly seen at power up and down and can result in premature device failure.

Power Supply Design Tips

My top three tips have been collated from years of experience in providing power supply design help to junior electronics engineers/technicians. I hope you find these equally helpful.

Power supply performance will be affected by loading, so when designing your circuits, analyze its performance under no load, typical load, and maximum load conditions. A power supply circuit that operates within specification under its maximum load may well be out of specification under other loading conditions.

Power supply performance will be affected by temperature, which is affected not only by its environment (ambient temperature and airflow) but also by factors such as loading. Therefore, thorough thermal analysis under all possible internal (input voltage, component tolerance, output loading) and external (thermal, noise) conditions are necessary to guarantee power supply performance in all scenarios.

Power supply performance will be affected by time; that is, component performance and values change over time. This effect is particularly noticeable in some types of capacitors. Therefore, design calculations need to take account of component tolerances over the life of the device. This issue applies to the power supply itself and the circuitry that the power supply drives. Therefore, the power supply will see changes to the performance of the circuitry as a load change.

Have more questions? Call an expert at Altium and discover how we can help you with your next PCB design. You can download a free trial of Altium Designer here.