Types of Printed Circuit Boards

Once you start designing Printed Circuit Boards, you’ll find that different applications require have specialized design requirements. In order to meet all your design requirements without sacrificing workflow productivity, you need PCB design software that is adaptable to any design requirements. Working with the best PCB design software with a unified design interface makes it easy to define and satisfy design requirements for your specific application.

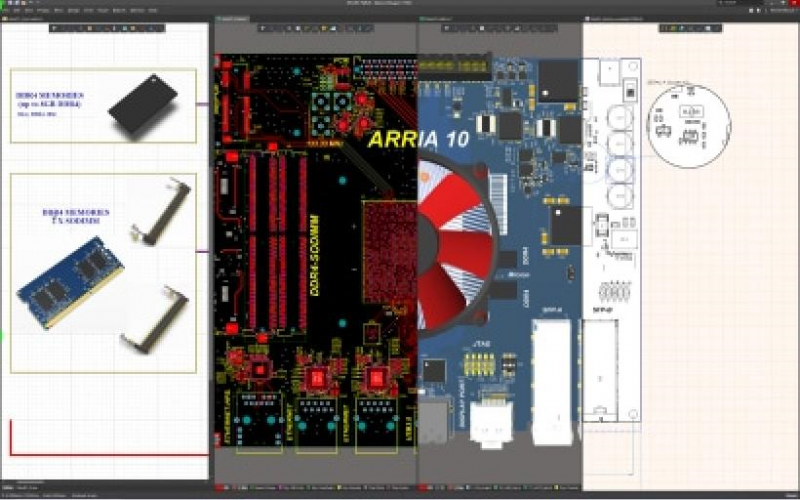

ALTIUM DESIGNER

A PCB design software package that lets you design unique PCBs for any application.

Unless you live completely off the grid, you’re surrounded by a large number of PCBs at any time. All of these Printed Circuit Boards are tailored for specific applications, and no single PCB is interchangeable between devices. The implicit customizability required in PCB design means that designers and engineers need design software that can be used to build PCBs for any application.

The types of printed circuit boards can vary: rigid PCBs, flexible PCBs, and rigid-flex PCBs being among some of the most current design processes. However, more can go into the types of printed circuit boards that you choose to use than just shape: what’s the copper demand of your printed circuit, and therefore what is the solder and solder mask necessities? Are there going to be surface mount components or through-hole technology used?

A single-sided PCB will have enough constraints and dimensions that require fine adjustments and precise calculations. But what about a multi-layer or even multi-board system? The types of printed circuit boards are ever-adapting to the technological capacities and needs that engineers are considering, but is your design software changing too?

PCB Design for Any Application

Not all Printed Circuit Boards are created equal, and most applications have their own set functional requirements. Likewise, not all PCB design software packages are immediately tailored to design for any and all applications. Simpler PCBs like a single-sided PCB layer, low-speed devices need a relatively fewer number of design rules and components than other devices. Whatever the application, your PCB design software should act as your best library editor and allow you to customize your design specifications.

All of this is accomplished with design rules. Many PCB design software packages contain industry-standard design rules, which saves designers a significant amount of time. Your design software should allow you to choose which design rules are appropriate for your application and allow you to specify your own design rules. Once it comes time to validate your design, your software should check your layout against these rules and make error correction easy.

Tailoring Your Design Software to Your PCB Application

Building towards specific applications takes design software that lets you define the parameters of your design environment. This includes defining customized design rules, building customized components, specifying your layer stackup, and your power/ground arrangement. All of these aspects form the foundation of designing for specific applications.

- Your PCB design software should include design rule checking and customization features. This will help ensure that your design can meet the requirements for your application. Learn more about design rule configuration and checking.

- Specific PCB applications often require creating customized components with specific functionality. Learn more about creating customized components.

- From board shape to layer stackup and base material options, your design software should include all the options you need to work with any board arrangement. Learn more about board customization.

Designing for Advanced Applications for PCB Design

If you’re designing a PCB, you’ll have to consider manufacturing at some point. Printed Circuit Board assembly and planning for it requires some knowledge for coating, base material, holes, vias, and the soldering performed on your board. PCB manufacturing and assembly is a large portion of any design, though, so having a baseline functional knowledge of the specifics for it will help immensely throughout the design and production stages.

Designing for advanced applications requires implementing a number of design and layout rules. Different types of PCBs need different design rules that depend on their capabilities. This is where working with design rule checking can greatly streamline your workflow. Imagine getting all the way through a design only to discover that a surface mount component is poking through the planned enclosure. Not everyone has the time to memorize every design rule for every application, and great PCB design software will include standardized design rules and allow you to build custom design rules.

Working with project templates that are tailored to your design rules is a great way to streamline your project workflow. Rather than flipping back and forth between an old and new design and copying design rules manually, you’ll have a head start on your new design when you work with a project template. You can enhance your workflow by quickly importing the design rules that your application requires.

Improve Your Productivity with Customized Design Rules and Templates

Overcoming all the design challenges that come with modern PCB design requires software that can streamline your workflow and seamlessly check your design against standardized design rules. Working with project templates that are tailored to your specific application reduces your design time and helps you keep your design settings organized in a single location.

- Design of modern PCBs for specific applications can create significant layout and routing challenges. Learn more about solving layout challenges in modern PCBs.

- You can simplify your design process for specific applications using project templates. Learn more about streamlining your workflow with PCB project templates.

- Rules checking features help you identify potential or immediate problems in your design before you receive your first shipment of boards from your manufacturer. These checks should be run at the schematic or layout level. Learn more about avoiding common design mistakes with rule checking.

Editing design rules in Altium Designer

Customized PCB Design in Altium Designer

If not you, then assuredly one of your coworkers or peers has worked a job where they’ve had to use multiple iterations of design software, programs, and features to get all the tools they need. But when considering the constantly increasing variety in types of printed circuit boards, you’ll want design software that can meet any solder and copper need for any printed circuit shape. The only holes should be the ones planned for in your design.

Other PCB design software packages separate the features you need into different modules, or even into entirely different programs. What sets Altium Designer apart from other design programs is the unification of design tools into a single interface. Your design tools will synchronize beautifully without having to move between separate modules. Instead of using piecemeal design software, look to the only PCB design platform that lets you operate in a single environment.

Get Access to Industry-standard Design Tools in Altium Designer

Whether you are designing simpler PCBs or you need to design a new smartphone, Altium Designer gives you access to all the best design tools demanded by the PCB design industry. You’ll have the ability to do more than just customize your user interface and design rules. Altium Designer gives you access to top-quality simulation tools, deliverable generation for the manufacturing process, and component creation tools.

- Altium Designer is built to maximize your productivity and improve your workflow. You can customize the design interface to fit your needs. Learn more about customizing the user interface in Altium Designer.

- Building devices with unique form factors are possible by synchronizing Altium Designer with an external design tool like Solidworks. Learn more about synchronizing Altium Designer with Solidworks.

- The PCB component editor in Altium Designer allows you to add proprietary components to your PCB. You’ll be able to tailor your PCB to any application. Learn more about creating schematic symbols and footprints in Altium Designer's component and library editor.

Altium Designer integrates all your tools in a single interface, helping you move from design to production without a hitch. Forget about working with separate design tools, try working in an environment that unifies your design, simulation, verification, and manufacturer deliverable tools in a single interface. This will give you the flexibility to implement the design strategy that works best for any type of PCB.

If you’re tired of working with separated design features that just won’t synchronize properly, the unified PCB design environment provided by Altium Designer can provide the solution. You’ll have the power to design any type of PCB for your unique application. When you work in an integrated design environment, you’ll be able to design your next unique electronic device to the highest standards.