Regulatory Compliance Through Traceable Component Sourcing

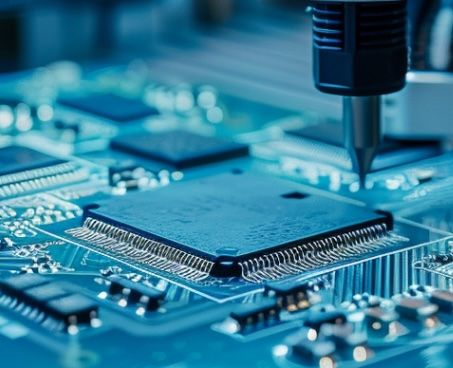

With the electronics industry deepening in complexity and dependence on critical components during times of shortage and regulatory change rising, it has become most important that PCB designers and manufacturers approach the development of printed circuit boards (PCBs) with adaptability and compliance in mind. Doing so requires meticulous attention to detail, especially when it comes to sourcing components.

With that in mind, traceable component sourcing, where the origin and journey of each component can be demonstrably tracked, has become an indispensable tool for PCB manufacturers.

The Challenge of Regulatory Compliance

With geopolitical conundrums causing supply chain disruption and a dearth in accessibility to certain natural resources, new initiatives related to ESG, and consumer awareness around the use of potentially harmful chemicals in electronics, global policymakers are working to change the way that the industry and mass demand impacts the planet. As a result, PCBs, which give life to every device, are now subject to a myriad of changing regulations that depend on their application. To name just a few:

- RoHS (Restriction of Hazardous Substances Directive 2011/65/EU): Restricts the use of certain hazardous materials like lead, mercury, and cadmium in electronic components and electrical equipment.

- REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals (EC) No 1907/2006): Requires extensive registration and notification for substances used in manufacturing, including those used in PCB components.

- Conflict Minerals Regulation (US: Dodd-Frank Wall Street Reform and Consumer Protection Act, Section 1502; EU: Regulation (EU) 2017/821): Both the US and EU editions aim to curb the trade of minerals sourced from conflict zones to promote ethical sourcing practices for minerals like tantalum, tin, tungsten, and gold commonly used in electronic components.

- IPC Standards: IPC, a trade association that standardizes electronic equipment manufacturing requirements, has, at present, “over 300+ active multilingual industry standards” that “[cover] nearly every stage of the electronics product development cycle.”

To meet these regulations, companies must command a solid knowledge of component composition and have in place a robust system for tracking their provenance. Traditional, paper-based methods of documentation are now, ultimately, inadequate in the pursuit of transparency and traceability due to the complexities of regulations, especially REACH, which has extensive chemical registration requirements.

The Benefits of Traceable Component Sourcing

With that in mind, putting in place a digital system for traceable component sourcing is the route forward, and it offers a multitude of benefits for PCB manufacturers that extend beyond just regulatory compliance:

- Enhanced regulatory compliance: Enables demonstrably compliant sourcing practices and reduces the risk of non-compliance penalties, which can and potential product recalls for violations of regulations like RoHS or the Conflict Minerals Regulation.

- Improved quality control: Provides a clear audit trail for components and facilitates the identification and isolation of potential quality issues early in the manufacturing process, which translates to fewer defective boards and reduced overall production cost.

- Supply chain transparency: Promotes transparency with stakeholders, which builds trust between third-parties and consumers involved in the creation process and use of the final product. Traceability allows manufacturers to demonstrate their commitment to ethical sourcing practices, which, given the proliferation of environmentally and socially conscious consumers, is now more important than ever before.

- Risk mitigation: Allows for quicker and more targeted responses to product recalls and safety concerns. If a company can pinpoint the exact source of a non-compliant component, manufacturers can isolate the issue and implement corrective actions fast, which will reduce disruption and any potential damage that faulty products might cause to brand reputation.

Technical Solutions for Traceability

The benefits of digitalization aside, we’d be remiss not to point out that there are so many options available for PCB manufacturers that intend to achieve traceable component sourcing, and more opportunities to optimize the process come into existence every year. Below are three such technologies that form the foundation of traceable solutions.

Blockchain Technology

A technology still in its infancy, blockchain, which offers an immutable digital record of component origin and movement throughout the supply chain, creates a cryptographically secure, distributed ledger that tracks every step a component takes from the raw material stage to its final destination in a PCB. Many leading companies, including Walmart, Coca-Cola, Ford, and Maersk, have now invested in blockchain to unlock this shared point of truth across their multinational supply chain networks.

Cloud-Based Traceability Systems

Cloud-based systems—PLM and, to a lesser extent, ERP, for example—provide a centralized platform for the management of component data, which gives companies access to real-time tracking and reporting. These systems, which nearly 92% of digital leaders have adopted, are optimized for ease of use, with user-friendly interfaces that capture, store, and analyze component data and enable real-time visibility into the supply chain so that manufacturers can track component movement and identify potential issues when they crop up.

Electronic Data Interchange (EDI)

EDI, software that sits between siloes to facilitate communication, streamlines data exchange between manufacturers and suppliers so stakeholders can access accurate and consistent component information. Specifically advantageous for PCB manufacturers, this system can automate the exchange of data points like part numbers, material composition, and certifications—removing the risk of human error, which is common in manual data entry tasks.

How to Implement Traceable Sourcing Practices

The implementation of traceable sourcing practices is, unfortunately, not a simple flick-of-the-switch scenario. It will take a multi-pronged approach by companies, and while that might represent a substantial initial outlay, the eventual gains do outweigh the expense. Here are the key considerations:

Partner with Reputable Suppliers

Building strong relationships with reliable suppliers is definitely the foundation of a successful traceability program. If all parties are on board, that is. Companies should collaborate with suppliers who already prioritize ethical sourcing and maintain robust traceability systems, or if they have an abundance of resources, they should consider working with suppliers willing to invest in upscaling their efforts with the company’s assistance. When looking for suppliers, focus on those that can provide comprehensive documentation on component origin, certifications, and compliance with relevant regulations.

Standardize Supply Chain-wide Data Collection

Data collection shouldn’t be siloed; with that in mind, establish clear protocols to capture and store the component data mentioned throughout this article (critical for RoHS compliance). By standardizing organizational-wide data collection, companies have consistency, which facilitates efficient analysis.

Invest in Traceability Technology

Leverage the appropriate technologies, including those listed above, to automate data collection and management. Investment in traceability tech streamlines the process and reduces the risk of human error; importantly, companies should look into solutions that integrate with existing manufacturing workflows and, as most are now using the ‘as-a-service’ model, offer scalability to accommodate future growth.

Conduct Regular Audits

The regular auditing of suppliers and internal processes helps companies to ensure the integrity and effectiveness of the traceability—and, indeed, any collaborative—system. Suppliers and third-party vendors should provide the company with regular updates. However, companies should err on the side of caution and conduct regular on-site visits to facilities to check in on workplace conditions, internal procedures, and employees to identify any potential gaps, weaknesses, or issues that might bring their brand into contention with governing bodies and consumer discontent.

Unfortunately for companies that used to toe the line between ethical and unethical practices, traceable component sourcing is no longer a luxury but a necessity for PCB manufacturers that intend to remain compliant. If companies can embrace available technologies and implement robust sourcing practices, manufacturers can guarantee that their PCBs meet the highest standards of quality and safety while also safeguarding brand reputation and market position. It’s getting even more competitive out there, and while traceability initiatives might affect the bottom line at first, it’s important to remember that these changes aren’t just about meeting regulations; compliance will, in the end, give companies a strategic advantage through hard-earned consumer trust—something achievable only through transparent and responsible manufacturing practices in a world full of lesser products.