Unveiling the Benefits of PLM for Modern PCB Designers

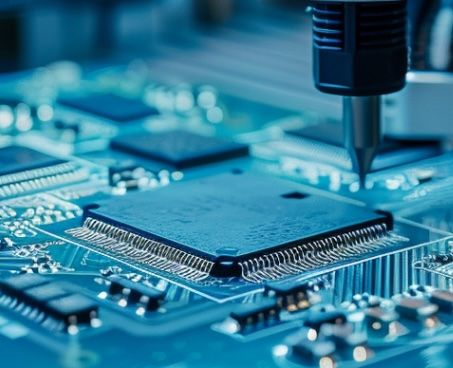

The printed circuit board design field is dynamic. It is constantly leveling up to meet the demands of smaller and more intricate yet more powerful electronics, and while traditional design software remains the cornerstone of this process, a new method to optimize design has emerged: product lifecycle management (PLM). The integration of PLM into businesses’ workflows has given PCB designers access to centralization that drives them towards greater efficiency, collaboration, and evolutionary innovation.

Here’s how.

Collaboration and Streamlined Communication

PLM serves as a centralized repository for all PCB design data. This means all stakeholders—from designers and engineers to manufacturers and quality assurance—can access the most current revisions, eliminating version control headaches and streamlining communication across previously siloed departments and teams. The version control features found within PLM systems operate to track changes and are meticulous in that action, assisting designers in rollbacks when necessary. It’s a single source of truth that facilitates collaboration and change across iterations.

Efficiency and Minimizing Errors

As it can integrate easily with existing PCB design software, companies that invest in PLM find that it helps designers leverage familiar tools within the PLM platform itself. This eliminates the need for error-prone manual data transfer, which mitigates risks and frees up valuable time and resources for other, arguably more pressing tasks. The system can also automate tedious tasks such as generating Bills of Materials (BOMs) and manufacturing documentation, which frees designers to focus on core creative endeavors rather than admin—a burdensome and often elongated task.

Accelerating Time-to-Market

By streamlining collaboration and automating tasks, PLM acts as a time-compression device for design cycles. That equates to faster product launches, which gives companies a vital competitive edge in a growing, saturated industry. But the benefits don’t stop at speed. PLM, in some respects, is the epitome of the term “more haste, less speed”; the system helps designers to identify potential manufacturing roadblocks—from compliance and functionality issues to lack of component availability—early in the design phase to prevent potential costly delays downstream, which is beneficial for both the bottom-line and, ultimately, the ticking clock.

Design Reusability and Knowledge Sharing

Given that PLM acts as a single source of truth for the entire process, it’s worth noting that it excels at storing and retrieving past design data, which allows designers to reuse successful components and layouts in new projects—a massive time save. It’s somewhat like having a library of proven designs at the click of a button, reading to be incorporated into new products. You can also create design libraries that facilitate the sharing of knowledge through the provision of a digital space where best practices and innovative concepts are readily accessible to all members of the team. This is especially beneficial for junior designers, who can study and learn from senior colleagues’ previous failures and successes, accelerating the training process and bringing fledgling prospects up to speed.

Supply Chain Visibility and Component Lifecycle Management

The supply chain is the lifeblood of any major operation. Especially manufacturing. The last few years have emphasized that in no uncertain way, with component and stock shortages affecting the greater majority of industries around the world. While the supply chain’s volatility, especially in light of geopolitical tensions and natural disasters, is unpredictable, PLM does at least give its users access to real-time insights into component availability, which helps designers make informed choices during the creation process. This proactive approach to design decisions lessens the risk of encountering supply chain disruptions and the consequent scrambling for alternative parts later in development. Not only that, PLM tracks component life cycles, alerts designers, and suggests alternatives when parts are nearing obsolescence—a level of foresight that helps designers maintain manufacturability without a sudden breakdown.

Advanced Change Management and Design for Manufacturability (DFM)

Beyond the revision management that PLM enables, it also facilitates the creation of comprehensive change management workflows, which make sure all stakeholders are notified and involved in the approval process of designs. This reduces the risk of introducing errors during design modifications, ensures a review process that is transparent and efficient, and mitigates the potential for misunderstanding between departments. Companies can also integrate PLM systems with their DFM tools to help designers identify and address potential manufacturing issues early in the design phase; this development allows designers to produce functional and manufacturable hardware at reduced production cost and with an unhindered transition from design to fabrication.

Design Quality and Cost Reduction

Businesses that vie for the top spot in the markets are under constant pressure from stakeholders to increase quality while decreasing cost. Sometimes, that seems like an unachievable feat. But PLM helps with that, too. By enabling early manufacturability analysis, the system helps designers conceptualize PCBs that are easier and cheaper to produce. Easier equals less manufacturability concerns, which results in notable cost savings. Importantly, in a period of time where products are considered more mediocre than in previous decades, PLM also packs Design for Reliability (DFR) practices, which allow designers to create PCBs with a longer lifespan and fewer potential failure points. That, when put into practice, goes a long way toward guaranteeing customer satisfaction, which is one of the most important factors in making or breaking a business, no matter how established it may be.

PLM: The PCB Designer’s Strategic Advantage

It goes without saying that the comprehensive suite of benefits offered to modern PCB designers by product lifecycle management is immense. While already pivotal team members, the enhancement facilitated by PLM turns designers into strategic partners within the product development process, with wider-ranging influence on other stakeholders than previously. This innovative system helps companies create a culture of well-devised collaboration and boosts efficiency across the board, accelerates time-to-market, opens up time and space for design innovation, and helps to guarantee quality and cost-reduction. It’s a human-tech augmentation that gives PCB designers a springboard to excel in their craft.

By integrating PLM into your company’s workflow, you are giving your PCB designers a significant competitive advantage and the ability to ensure their products are developed and manufactured with unparalleled effectiveness and efficiency. It’s facilitating a world where PCB design is not just about creating circuits but about making a lasting impact. That’s the benefit of PLM.

To elevate your PCB design standards and unlock unparalleled efficiency and innovation, look at Altium Enterprise Solutions, where we bring digital transformation to life with a comprehensive, digitally integrated electronic design solution for enterprises.