An Introduction to Wheatstone Bridge Circuits and Differential Amplifiers

If you need to measure resistance precisely, a Wheatstone bridge is a simple circuit that provides a way to do so by taking a voltage measurement. Despite the simplicity of a Wheatstone bridge, it can be a challenge to make use of one effectively. In this article, we’ll take a look at Wheatstone bridge circuits, how they work and how we can effectively use them with modern electronics.

Many sensor types use a Wheatstone bridge internally, as the resistance measured in the circuit can be linked back to some other phenomenon that causes the resistance of the sensor to change. You’ll find Wheatstone bridge circuits in all kinds of compression and tension-based devices, such as air and fluid pressure sensors, strain gauges and more. While in some devices, there is an integrated circuit providing amplification of minute voltage changes, it’s also common to have direct access to the bridge, such as in a strain gauge/load cell.

Wheatstone bridges are one of those circuits that you might not feel like you’ve come across before, but you probably have inside some device or sensor you are using. Virtually every digital scale uses a Wheatstone bridge-based load cell, for example. The simplicity and effectiveness of a Wheatstone bridge makes it an incredibly powerful circuit, even if it does have a relatively niche application.

Note: There is some math in this article to help you understand how to determine the unknown resistance, but it is very simple! It might look like a bunch of formulas, but don’t tune out, as it’s the same formula broken down in different ways with the hope of making it easier to explain.

What is a Wheatstone Bridge?

A Wheatstone bridge uses two balanced legs in a bridge circuit (i.e., two voltage dividers) to provide a link between the voltage across the bridge circuit and some unknown resistance of one resistor in the Wheatstone bridge. The simplest type of Wheatstone bridge balances two legs of a bridge circuit, one leg of which includes the unknown component. In other words, if you know the values of three of the resistors, you can calculate the resistance of an unknown fourth resistor simply by measuring the voltage across the bridge. This circuit provides a voltage change as the resistance changes, allowing a microcontroller or other device to measure determine the resistance of the unknown element by reading the voltage through an ADC.

Typical applications for a Wheatstone bridge circuits in modern devices primarily include strain gauges, load cells, pressure sensors, relative humidity sensors, thermistors, and resistance temperature detector (RTD) probes. The Wheatstone bridge is capable of measuring minimal changes in resistance down to milliOhm levels as long as the ADC being used has sufficient resolution (high bit depth). Note that there are many bridge topologies other than a Wheatstone bridge. Other bridge circuits can be used to measure capacitance, inductance, and impedance; however, we will not be looking into those in this article.

Taking a Resistance Measurement with a Wheatstone Bridge Circuit

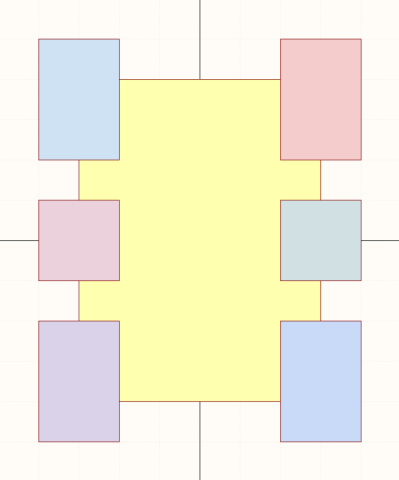

The working principle of the bridge is the use of four resistors typically represented by a diamond shape. In Altium, we need to present this as a box-like shape as shown above. Here, we have three known resistances and a fourth resistor with an unknown value. When we supply a voltage across to the top and bottom terminals of the bridge as shown above, the bridge creates two parallel voltage dividers. It the voltage is measured across the centre of the bridge, it can be converted converted into a resistance using the formulas I'll show here. These formulas are simple enough that you can implement them in a small MCU.

To begin, from looking at the above circuit, you should be able to see that the voltage between V0 and V1 will be equal to 0 V when the four resistors satisfy the following relation.

Here, R? is the unknown resistor, and the other three resistors have known value. Here, we can solve the above formula for R? for this particular case where the voltage between V0 and V1 is equal to 0 V.

This condition can be used to calibrate the Wheatstone bridge with a varistor or a potentiometer, but it does not help us determine an unknown resistor in other cases.

To determine the value of the unknown resistor, let’s take the circuit shown above a little further. The voltage across R2 as measured at V0 will be:

In the bridge above, know that this will be made up of 10K resistors so V0 will be half the input voltage of 5V:

In other words, V0 should always be 2.5 V if we use high-quality resistors. This will be the case no matter what happens to the unknown resistor. Now the voltage divider with port V1 has our unknown resistor, so we have a similar equation for the voltage across R? (as measured at port V1):

Because we are measuring the difference between the voltages at the two ports, we can write V = V0 - V1 and substitute the above equations into this expression. This gives us the following:

Note that you can see we will have V equal to 0 if the unknown resistor R? is equal to R3*R2/R1, i.e., if the bridge is balanced.

With V0 and V1 connected to a differential ADC, we can measure the positive and negative voltage differential using a microcontroller or other device. The differential voltage is caused by the unknown resistor not being equal to the other resistor - the bridge being unbalanced. As a note, in practical applications, you will likely need to amplify the signal before connecting it to a differential amplifier.

With a bit of algebra, and with a measurement of this voltage differential V, we can solve the above equation for R? and calculate the value of the unknown resistor:

Remember, V is the differential across V0/V1, and VS is the supply voltage given to the Wheatstone bridge. In our example with R1 = R2 = R3 = 10 kOhms, we can calculate the unknown resistance R? if we measured a 1 V difference across the bridge. In this case, the unknown resistance would be:

You can confirm this by calculating the voltage output from both dividers individually, one providing 2.5 V (the known one) and the other to provide 1.5 V. If you want an online calculator as a sanity check, I like the one on Ohms Law Calculator. As someone who has dyslexia, even basic formulas can trip me up, so I typically rely on online calculators as a sanity check - don’t feel bad if you need an online calculator too!

Typically you’ll find a Wheatstone bridge application in the real world will give you much less substantial changes in resistance. However, so you’ll want to use one with an amplifier or an ADC with a programmable gain amplifier. For example, with a load cell, it’s not uncommon for me to use 128 times amplification or more.

Using a Wheatstone Bridge Circuit with an Amplifier

While there might be applications where you can use a Wheatstone bridge directly, real world applications for a Wheatstone bridge typically result in microvolts or millivolts of differential at best. As an example in my article on the Octopart Blog, Reading Small Signal Voltages, I reference a load cell which uses a pretty typical Wheatstone bridge strain gauge. The 100kg load cell only provides a voltage change of 50μV per kilogram. This isn’t much use for plugging directly into a microcontroller or other logic. So how do you use it?

Differential Amplifier

The most basic way to make the voltage change more useful is using a general-purpose rail-to-rail differential amplifier, no specialised ADC required!

By using a differential amplifier configuration, we can amplify the difference between the two Wheatstone bridge voltage dividers which can then be fed to a microcontroller ADC, or other device. The Wheatstone bridge circuit converts the resistance change into a voltage change, and the amplifier makes the voltage change useful. This is quite useful when working with sensors that exhibit very small changes in resistance as now the voltage difference can be read easily.

Alternatively, you could use an instrumentation amplifier instead of a general-purpose differential amplifier for greater precision.

High Impedance Amplifier

For additional precision, we can first buffer the output from the Wheatstone bridge. Due to the high input impedance, the stability and precision of the circuit are improved. You can implement this with buffer amplifiers (unity gain) or just use another operational amplifier with no gain as a buffer. By utilising a quad amplifier package, you can buffer and then amplify with a single IC package.

Instrumentation Amplifier

We could, at this point, take this circuit a step further by adding some additional resistors to build an instrumentation amplifier. Instead, we’ll take the more precise, compact and precise option and simple design using an instrumentation amplifier IC. An instrumentation amplifier is going to allow us to very precisely amplify the signal without having to worry overly much about using 0.1% or better resistors for the operational amplifiers or tune every circuit we build for precision. The IC manufacturer has already done that at the factory. While an instrumentation amplifier is more expensive than a single general-purpose operational amplifier, it offers cost savings in being an available IC solution without requiring high precision external components to make it function correctly. The space savings, and BOM line savings (and therefore inventory and feeders on a pick and place line) also should not be ignored.

An instrumentation amplifier is going to allow us to precisely amplify signals between the two inputs while also having excellent common-mode rejection. This way, any electrical noise picked up on our Wheatstone bridge’s cables or traces will be ignored as it should be nearly identical to both of our nets. The gain setting resistor is separate to our inputs, easy to calculate and simple to route. The gain resistor can also be set using a digital pot, or some instrumentation amplifiers have built-in digital pots which can be set over common protocols such as I2C or SPI.

As an added bonus, many instrumentation amplifiers have a reference pin which allows you to supply a DC bias to the signal, further simplifying reading the output of a Wheatstone bridge circuit from a single-supply device like a microcontroller.

You will find the gain function for the amplifier in the datasheet, for example, in the Texas Instruments INA821 datasheet we find the function:

By using this equation, we can easily calculate the correct value for Rg to obtain the gain we wish our amplifier to have. If we wanted to have 100 gain, we could simplify and rearrange the equation to:

Therefore, a 499 ohm resistor for RG will give us almost exactly 100 gain.

If you struggle a bit with rearranging formulas/algebraic equations, as always there is a great online calculator available - in this case, check out the one at SymbolAB. To calculate 100 gain as I did above, you could enter in something like 100 = 1+(49400/x), and it will solve x for you.

This would give us a circuit (without decoupling caps) which looks as we have above - much more straightforward than the other circuit’s we’ve looked at right?

Configuring Gain

You might be wondering how much gain you need, and what you should set the reference pin on the instrumentation amplifier to. Analog Devices has a handy online tool called Diamond Plot. This tool allows you to choose the parameters, such as gain/supply voltage and Vref so you can maximize the instrumentation amplifiers working range and adjust your instrumentation amplifier to your ADC or other application. By using a tool like this, you can ensure you create the largest dynamic range possible to have the highest resolution signal you can. The tool will also generate handy warnings if you have incorrect parameters. Different factors could lead to internal signal saturation, and this could reduce the maximum dynamic range of your signal, or lead to clipping and other issues.

For example:

- The input voltage signal is too high for the preset gain

- The reference voltage is too high for the generated output voltage signal

- The power supply voltage is too low

This tool could help to choose the correct parameters for your instrumentation amplifier specific to your application.

Suppose we change the initially displayed example’s parameters. In that case, you can see it will tell us we’ve done something wrong and give suggestions on what to change to bring the signal within the device’s capabilities.

This tool is designed explicitly for Analog Devices components. However, there is a broad range of Analog Devices parts available to be used with it. If you wanted to use a device from a competitor, you can likely find an AD part with similar parameters and use that in the tool.

Instrumentation Amplifier Examples

If you’re keen to use an instrumentation amplifier with your Wheatstone bridge, consider some of these budget-friendly options from Analog Devices, Texas Instruments and Maxim Integrated.

|

Parameter |

INA332 |

MAX4208 |

AD8293G160 |

|

Type |

Rail-To-Rail |

Rail-To-Rail |

Rail-To-Rail |

|

Range of Gain |

1000 V/V |

100 V/V |

160 V/V |

|

Gain Error |

+/- 2 ppm/Celsius |

+/- 25 ppm/Celsius |

+/- 5 ppm/Celsius |

|

Slew Rate |

5 V/us |

0.08 V/us |

~1 V/ ms (Filter Limited) |

|

-3 dB Bandwidth |

2 MHz |

750 kHz |

500 Hz |

|

Offset Voltage |

2 mV |

3 uV |

9 uV |

|

Offset Voltage |

2 mV |

3 uV |

9 uV |

|

Input Bias |

0.5 pA |

1 pA |

400 pA |

|

Current Supply |

415 uA |

1.4 mA |

1 mA |

|

Output Current |

48 mA |

25 mA |

35 mA |

|

OCMRR |

73 dB |

96 dB |

140 dB |

|

Supply Voltage |

2.5 - 5.5 Single |

2.85 - 5.5 Single |

1.8 - 5.5 Single |

|

Manufacturer |

Texas Instruments |

Maxim Integrated |

Analog Devices |

These instrumentation amps are great examples of budget-friendly options that can be used in your projects. Each has its strengths and weaknesses, with a wide range of capabilities represented in just these three components depending on your applications.

In Conclusion

A Wheatstone bridge is a classic circuit, with the original design and concept dating back almost two hundred years. There are not very many standard circuits that we use in modern electronics which have stood the test of time as well as the Wheatstone bridge. The simplicity of the circuit combined with its utility ensures we will continue to be using them long into the future.

We’ve only covered the basics in this article. There are ways to improve the linearity of Wheatstone bridge circuits. Depending on the type of sensor and how you are consuming the output of the bridge, we can increase the precision and reliability of the readings. We’ll cover those aspects more in-depth in sensor-specific articles in the future. There is also a wide range of other bridge circuits which, whilst generally not as popular as the Wheatstone bridge, still find uses for measuring capacitance and inductance among other values.

If you’re looking for an easy way to quickly improve your existing Wheatstone bridge circuit implementation, changing from a single supply to a dual supply is a very quick and easy way to gain resolution, flatten the response curve and improve noise immunity. If you’re currently using a 5V and GND circuit, for example, adding a charge pump based inverting switched-mode power supply will cost you three cheap components and give you a -5V supply. By having a +5V/-5V supply on your bridge circuit, your output will be balanced at 0v/ground. This improves rejection and any dual supply rail-to-rail general-purpose or instrumentation amplifier will be able to make use of the output signal without any changes required. The only other change you will need to consider is biasing the output of the amplifier to ensure the minimum and maximum voltages are within the range of what your ADC or other circuitry can easily read.